Negative-pressure urotropin distillation device

A negative pressure distillation, urotropine technology, applied in distillation separation, vacuum distillation, organic chemistry and other directions, can solve the problems of affecting the dehydration capacity of the system, inconvenient operation, affecting the overall water balance of production, etc., and achieve a change in operability. , The effect of reducing labor intensity and reducing leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

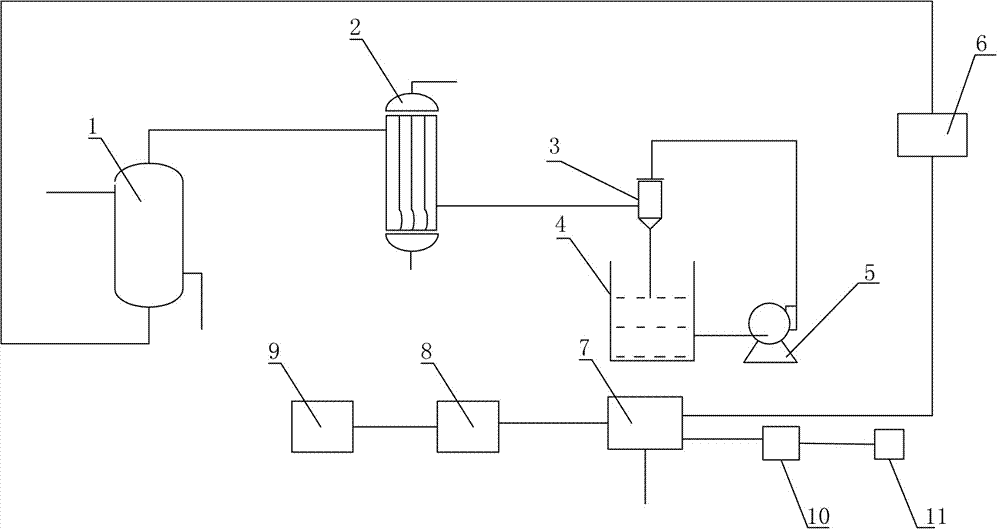

[0012] like figure 1 Shown, a kind of urotropine negative pressure distillation device comprises still 1, and described still 1 is connected with condenser 2 by pipeline, and described condenser 2 is connected with jet vacuum pump 3 by pipeline, and described jet vacuum pump 3 is connected to the circulating water pump 5 through a pipeline, and the collecting tank 4 is connected to the circulating water pump 5 through a pipeline, and the jet vacuum pump 3 is placed above the collecting tank 4, and the height difference between the bottom of the still 2 and the upper edge of the collecting tank 4 is 2-3 meters.

[0013] The still 1 is connected to the suction filter tank 6 through a pipeline, and the suction filter tank 6 is connected to a dryer 7 through a pipeline, and the dryer 7 is connected to an induced draft fan 8 through a pipeline, and the induced draft fan 8 passes through a pipeline. The pipeline is connected with the cyclone separator 9.

[0014] The dryer 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com