Hub casting mold

A technology for casting molds and hubs, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of reduced production quantity, reduced production efficiency, and low utilization rate of molten iron, and achieves reduced area, improved production efficiency, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

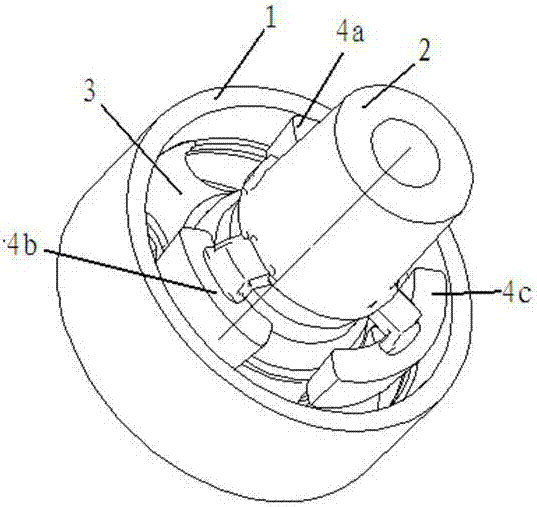

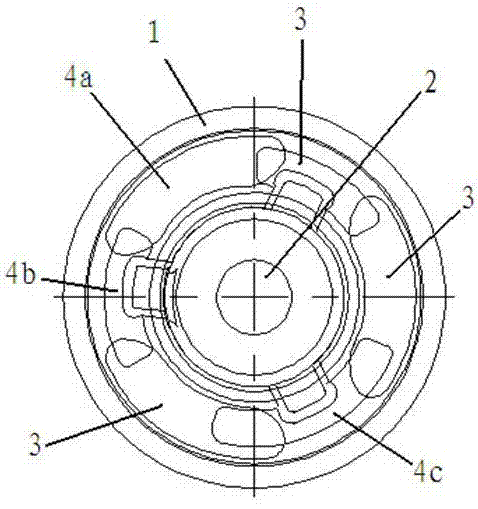

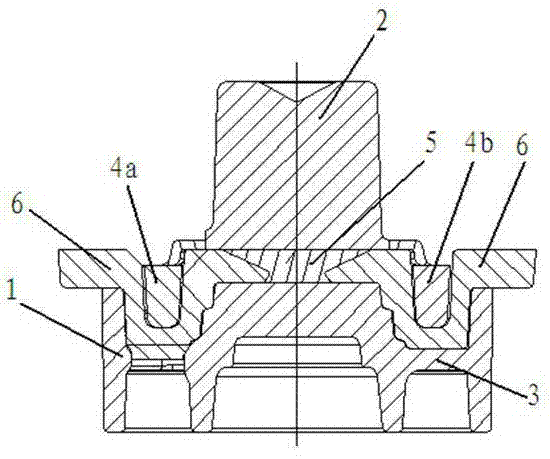

[0012] Such as figure 1 , figure 2 , image 3 As shown, the upper end of the center of the hub is connected to a riser 2 through the riser neck 5, the riser neck 5 is an inverted cone, and the lower end of the riser 2 is provided with heat-affected blocks 4a, 4b, 4c, between the center of the hub and the outer ring 1, corresponding to the position of the spokes 3, a sand core 6 is provided on one side of the hub to reduce the size of the riser neck 5 and form heat-affected blocks 4a, 4b, 4c, and the setting of the sand core 6 can reduce the riser neck The size of the mouth neck 5 can be removed by using a hand hammer, which solves the trouble of using a lathe to remove and greatly reduces production costs; setting heat-affected blocks 4a, 4b, 4c at the spokes 3 can delay the solidification of the connected spokes later than The solidification time at the joint between the outer ring and the web ensures that the quality of the outer ring is qualified; when working, the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com