A method of laser-friction stir welding diamond tools

A diamond tool and friction stir technology, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of diamond thermal damage, graphitization, etc., and achieve the effect of improving the bonding strength of the interface and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

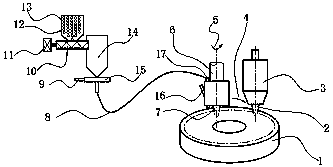

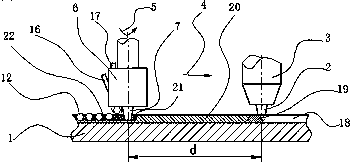

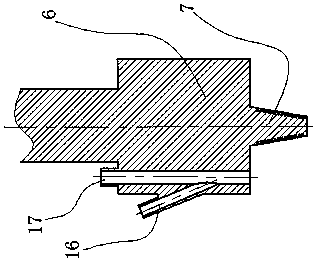

[0026] The following will be combined with Figure 1-3 The technical solution of the present invention will be described in detail along with specific embodiments.

[0027] Such as figure 1 As shown, the substrate of the diamond workpiece is 45 steel, and the metal bond is nickel-based solder. The laser beam is vertically incident on the upper surface of the metal bond powder to realize the connection between the metal bond powder and the substrate. At the same time, the friction stir welding system behind the laser beam Stirring is used to stir the solidified brazing seam, and simultaneously inject diamond abrasive grains into the friction stir welding pool to realize the solid phase connection between diamond abrasive grains and metal bond.

[0028] In this embodiment, the method for laser-friction stir welding a diamond tool includes the following steps.

[0029] Step 1: Preparing the substrate 1 of the diamond tool by mechanical processing, derusting, polishing and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com