A method for realizing heterogeneous welding of titanium alloy and aluminum alloy

An aluminum alloy and titanium alloy technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problem of poor joint plasticity and high temperature performance, affecting the service life of welded parts, and the decline in mechanical properties of welds, etc. problem, to achieve the effect of reducing heat, good welding reliability, and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

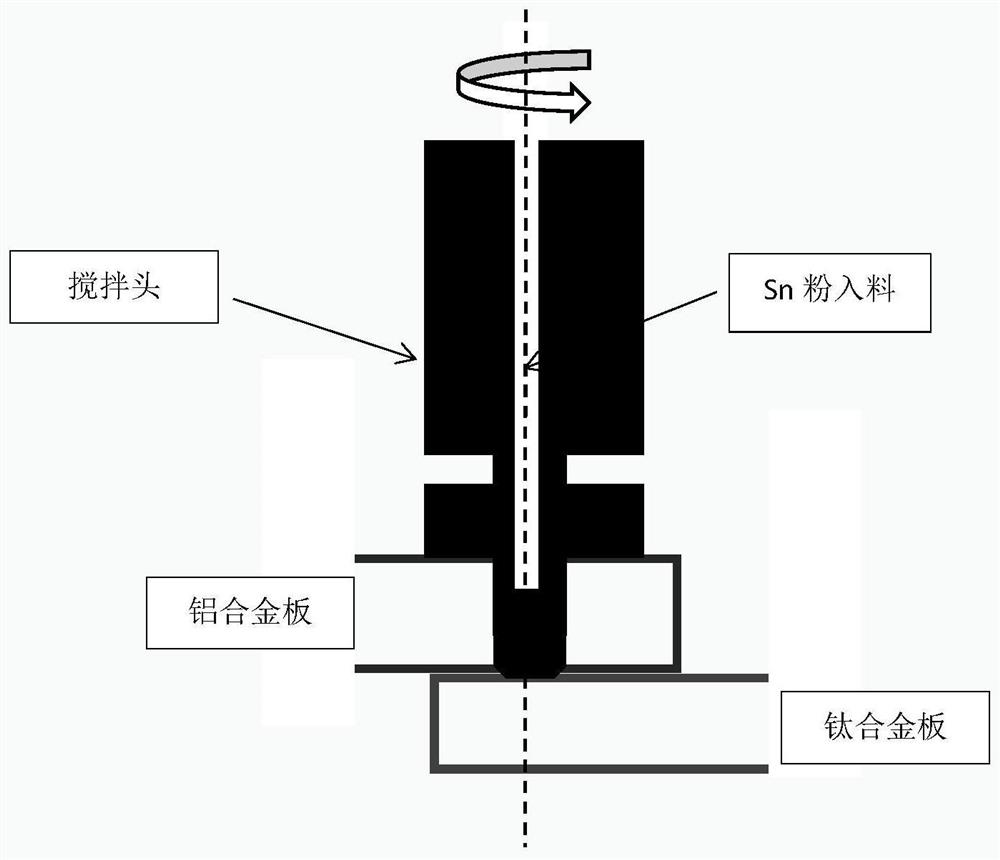

[0026] A method for realizing heterogeneous welding of titanium alloy and aluminum alloy, prepared according to the following steps:

[0027] (1) Design the stirring head: H13 hot work die steel is selected as the material of the stirring friction head, the diameter of the friction stirring needle is 8mm, and the size of the center hole is 4mm.

[0028] (2) Cleaning before welding: Prepare an 8mm thick aluminum alloy plate and a 2mm thick pure titanium plate, use a lathe to flatten the surface of the titanium alloy and aluminum alloy plate, and use alcohol to clean;

[0029] (3) Stir welding: lap the titanium alloy plate and the aluminum alloy plate, the aluminum alloy plate is on top, and fix it on the welding fixture, the stirring head goes deep into the joint position, and enters 0.5mm into the titanium plate, adjust the speed of the stirring head 800r·min -1 And the welding speed is 100mm·min -1 , start friction stir welding;

Embodiment example 2

[0033] A method for realizing heterogeneous welding of titanium alloy and aluminum alloy, prepared according to the following steps:

[0034] (1) Design of the stirring head: W-Re hard alloy is selected as the material of the friction stirring head, the thickness of the friction stirring needle is 10mm, and the size of the center hole is 5mm.

[0035] (2) Cleaning before welding: prepare a 10mm thick aluminum alloy plate and a 2mm thick titanium alloy TC4 plate, use a lathe to flatten the surface of the plate and clean it with acetone;

[0036] (3) Stir welding: lap the titanium alloy plate and the aluminum alloy plate, the aluminum alloy plate is on top, and fix it on the welding fixture, the stirring head goes deep into the joint position, does not enter the titanium plate but contacts it, adjust the stirring The head speed is 700r·min -1 And the welding speed is 75mm·min -1 , start friction stir welding;

[0037] (4) Welding powder feeding: use the air compressor powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com