A method of rotational friction welding of titanium alloy and steel heterogeneous

A technology of rotary friction welding and titanium alloys, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of poor joint plasticity and high temperature performance, affecting the service life of welded parts, affecting the mechanical properties of welded joints, etc. Achieve the effect of good welding interface, improve welding efficiency and good welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

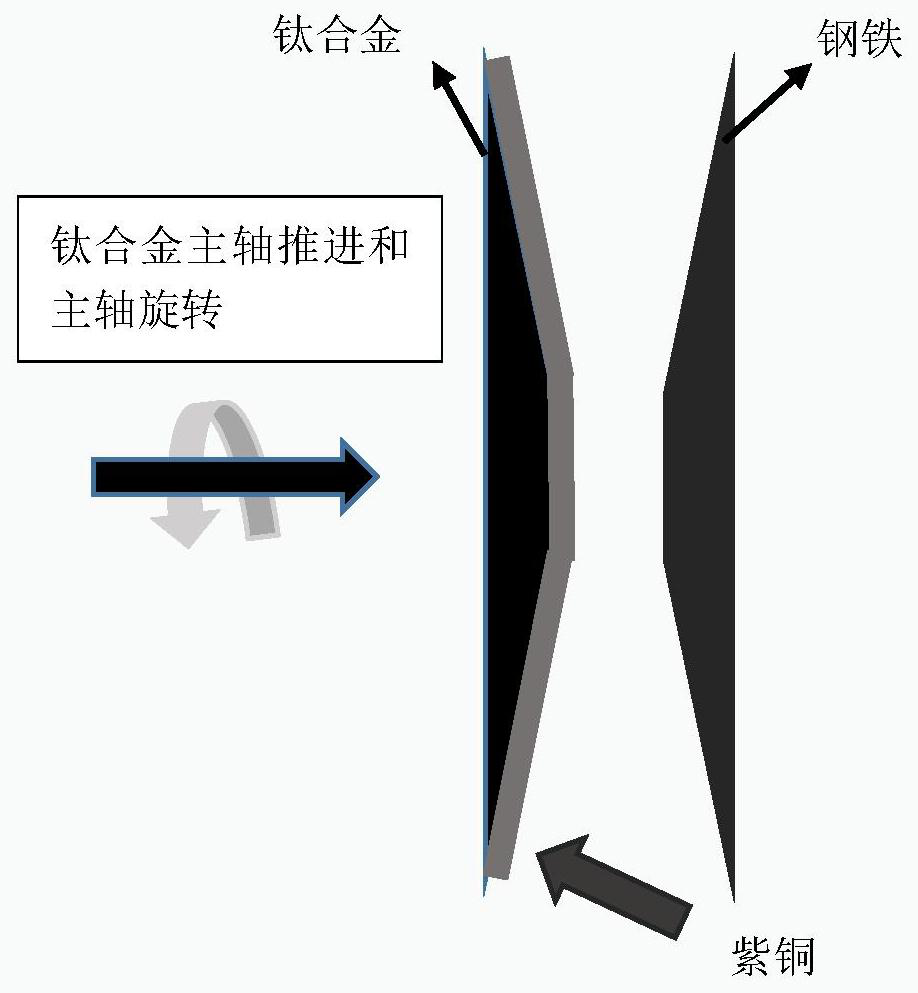

[0028] A method for rotational friction welding of titanium alloy and steel heterogeneity. Prepare as follows:

[0029] (1) Process the end face: chamfer the end face of TC4 titanium alloy and 316 stainless steel with a slope of 15°, leave a center circle with a diameter of 10mm and grind it to smooth;

[0030] (2) Titanium-copper pressure welding: pressure-weld a red copper sheet with the same diameter and a thickness of 1 mm to the end face of TC4 at a temperature of 950 ° C, a pressure of 10 MPa, and a pressure-welding time of 20 minutes.

[0031] (3) Cleaning before welding: Use a turning tool to remove the rough surface and scrub it with acetone.

[0032] (4) Rotary welding: fix TC4 to the main shaft, perform autorotation (700rpm) and gradually contact the fixed 316 stainless steel end face, the distance between the two is 100mm, the primary and secondary pressures are 400, 800kg respectively, and the upsetting pressure It is 1500kg, and the forward speed of the main sh...

Embodiment example 2

[0035] A method for rotational friction welding of titanium alloy and steel heterogeneity. Prepare as follows:

[0036] (1) Processing end face: TA2 pure titanium and 45# steel end face are chamfered, the slope is 5°, and the diameter of the central circle is 10mm and polished to smooth;

[0037] (2) Titanium-copper pressure welding: pressure-weld a red copper sheet with the same diameter and a thickness of 1 mm to the end face of TA2 at a temperature of 900 ° C, a pressure of 5 MPa, and a pressure-welding time of 30 minutes.

[0038] (3) Cleaning before welding: Use a turning tool to remove the rough surface and scrub it with acetone.

[0039] (4) Spin welding: fix pure titanium to the main shaft, perform autorotation (800rpm) and gradually contact with the fixed 45# steel end face, the distance between the two is 150mm, the primary and secondary pressures are 500, 1000kg respectively, and the top The forging force is 1500kg, and the forward speed of the spindle is 1mm / s. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com