Micro spot welding technology of nickel plated copper wiring harness and copper plate

A nickel-plated copper and wire harness technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of affecting welding quality, softening of copper material, and high melting temperature of nickel coating, so as to improve the quality of solder joints and reduce the The degree of bending deformation and the effect of improving the strength of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described according to the drawings and embodiments below.

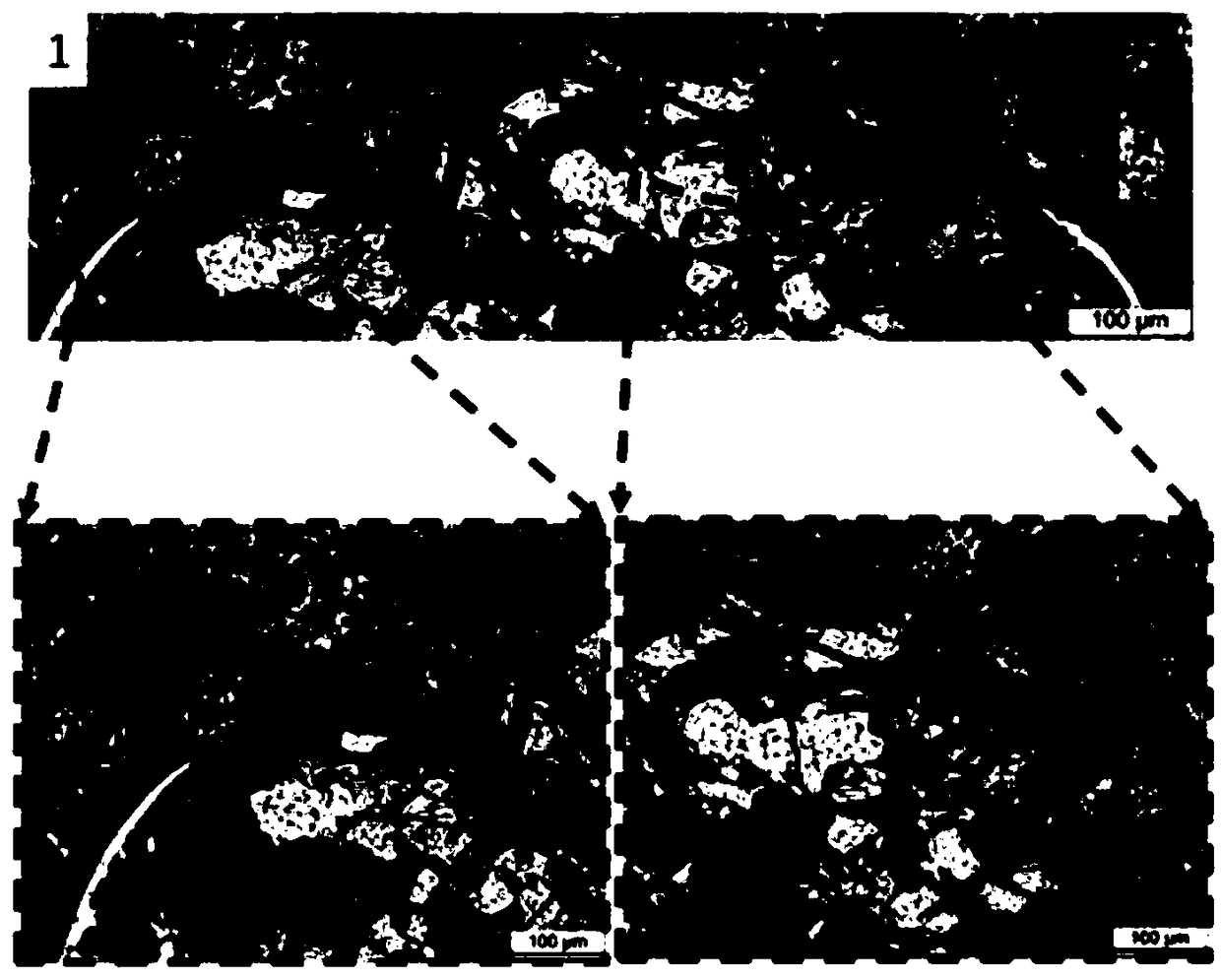

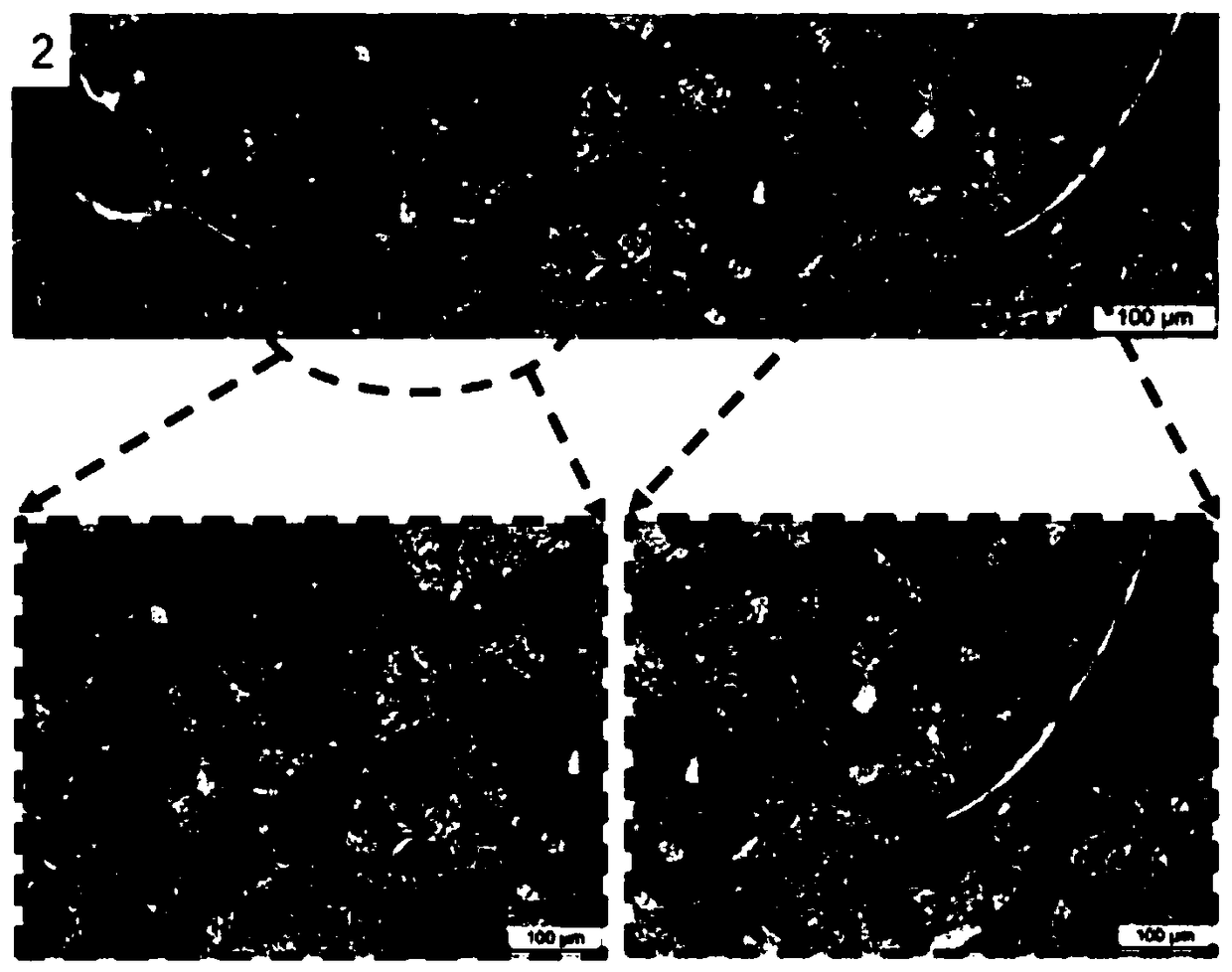

[0028] The micro-spot welding process of the nickel-plated copper wire harness and the copper plate includes the preloading of the welded parts, the first welding, the first cooling, the second welding, the second cooling, the third welding and the butt welding The specific operation steps of the whole welding are: first clamp the nickel-plated copper wire harness and copper plate to be welded together on the tooling, start the switch of the MIYACHI ISB-800A model spot welding machine, and the positioned workpiece to be welded will automatically run to Below the electrode, the welding head is lowered, and the workpiece to be welded enters the middle of the tungsten-copper electrode. The electrode will clamp the nickel-plated copper wire harness and the copper plate to be welded. The clamping force can be 150-180N. The clamping force of this embodiment is preferably 170N to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com