Composite phosphorus removing agent and preparation method thereof

A phosphorus removal agent and composite technology, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve the problem of large sludge production, low product utilization rate, and metals that are unfavorable to biological systems Growth and other problems, to achieve the effect of improving biological phosphorus removal efficiency, improving microbial activity, and reducing treatment pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A compound type phosphorus removal agent, the composition of the compound type phosphorus removal agent in weight percent is as follows: the mass percentage of sugar is 28%, the mass percentage of soda ash is 0.08%, the mass percentage of magnesium salt is 1.2%, and the mass percentage of calcium salt is 0.1% , and the rest is water.

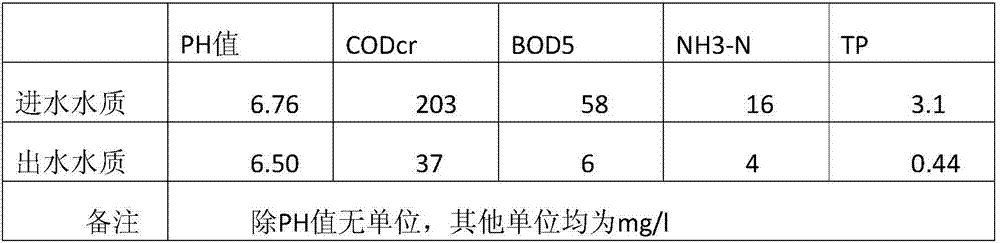

[0025] Take the actual application of domestic sewage treatment plants containing industrial sewage in the south as an example. The sewage treatment plant adopts the A2O process, and the compound phosphorus removal agent of Example 1 is added to the aerobic section. The treatment data are as follows:

[0026]

[0027] The proportion of inorganic salts that form precipitates in the agent is only 1.58%, which is much less than that of conventional inorganic phosphorus removal agents that rely solely on precipitation to remove phosphorus.

Embodiment 2

[0029] A compound type phosphorus removal agent, the weight percent composition of the compound type phosphorus removal agent is as follows: the mass percentage of sugar is 41%, the mass percentage of soda ash is 0.2%, the mass percentage of magnesium salt is 1.52%, and the mass percentage of calcium salt is 0.33% , and the rest is water.

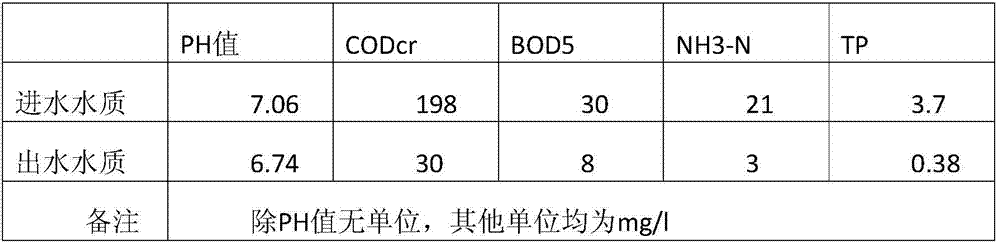

[0030] Taking the practical application of domestic sewage treatment plants containing industrial sewage in the south as an example, the sewage treatment plant adopts the A2O process, and the compound phosphorus removal agent of Example 2 is added to the aerobic section. The treatment data are as follows:

[0031]

[0032] The proportion of inorganic salts that form precipitates in the agent is only 1.51%, which is much less than the sludge formed by conventional inorganic phosphorus removal agents that rely solely on precipitation to remove phosphorus.

Embodiment 3

[0034] A compound type phosphorus removal agent, the weight percent composition of the compound type phosphorus removal agent is as follows: the mass percentage of sugar is 35%, the mass percentage of soda ash is 0.14%, the mass percentage of magnesium salt is 1.36%, and the mass percentage of calcium salt is 0.21% , and the rest is water.

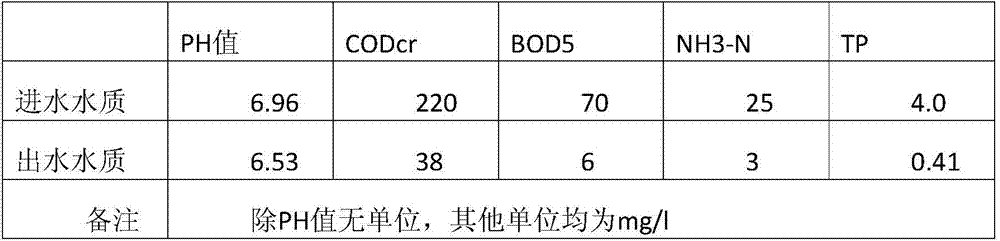

[0035] Taking the actual application of domestic sewage treatment plants containing industrial sewage in the south as an example, the sewage treatment plant adopts the A2O process, and the compound phosphorus removal agent of Example 3 is added to the aerobic section. The treatment data are as follows:

[0036]

[0037] The proportion of inorganic salts that form precipitates in the agent is only 1.57%, which is much less than the sludge formed by conventional inorganic phosphorus removal agents that rely solely on precipitation to remove phosphorus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com