A kind of preparation method and application of burdock polysaccharide pyrolyzate

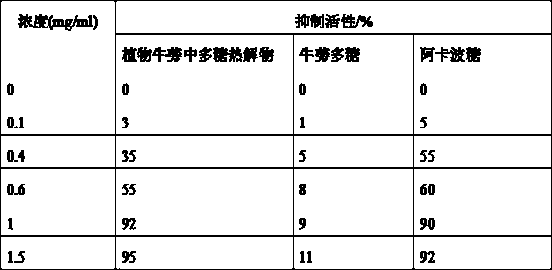

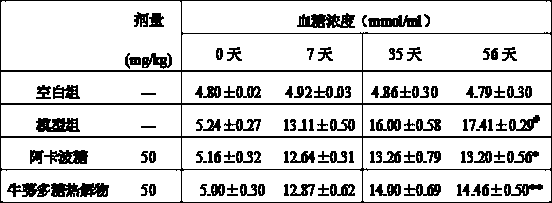

A technology of burdock polysaccharide and pyrolysate, which is applied in the field of preparation of burdock polysaccharide pyrolysate, can solve the problems of uneven structure, unstable activity and low activity of burdock polysaccharide, and achieves inhibition of α-glucosidase activity, structure and The effect of stable ingredients and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

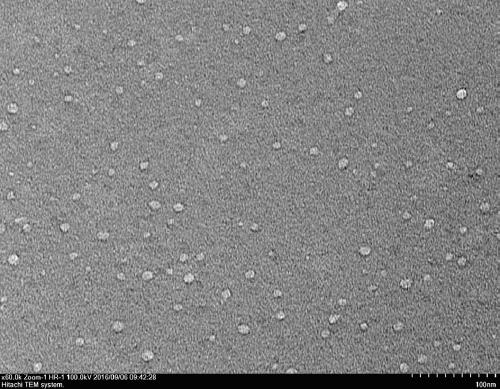

Image

Examples

preparation example Construction

[0035] A preparation method of burdock polysaccharide pyrolyzate, comprising the following steps:

[0036] ①Add burdock polysaccharide and water with a mass ratio of 1:1~100 into the reaction vessel, and pyrolyze it at a pyrolysis temperature of 100~260°C for 1~8 hours to obtain a mixed solution;

[0037] ②Centrifuge the mixture obtained in step ① at a speed of 1000~10000r / min for 1~5 minutes, take the supernatant and concentrate the volume to 0.5~0.1 times the original volume at 50~100°C to obtain a concentrate;

[0038] ③ Dialyzing the concentrated solution obtained in step ② with a dialysis bag with a molecular weight cut-off of 500-3000 for 1-3 days to obtain a retentate, and drying the retentate to obtain pyrolyzed burdock polysaccharide.

[0039] Preferably, the burdock polysaccharide is prepared according to the following steps:

[0040] ⑴Fresh burdock roots are washed and dried, peeled, sliced, add 2 to 5 times the weight of water, and extract twice at 75~85°C, the fi...

Embodiment 1

[0065] A preparation method of burdock polysaccharide pyrolyzate, comprising the following steps:

[0066] ①Add burdock polysaccharide and water with a mass ratio of 1:1 into the reaction vessel, and pyrolyze it at a pyrolysis temperature of 100°C for 8 hours to obtain a mixed solution;

[0067] ②Centrifuge the mixture obtained in step ① at a speed of 1000r / min for 5 minutes, take the supernatant and concentrate it at 50°C to 0.5 times its original volume to obtain a concentrate;

[0068] ③The concentrated solution obtained in step ② was dialyzed for 1 day with a dialysis bag with a molecular weight cut-off of 500 to obtain a retained solution, which was dried by rotary evaporation to obtain pyrolyzed burdock polysaccharide.

Embodiment 2

[0070] A preparation method of burdock polysaccharide pyrolyzate, comprising the following steps:

[0071] ① Add burdock polysaccharide and water with a mass ratio of 1:100 into the reaction vessel, and pyrolyze it at a pyrolysis temperature of 260°C for 1 hour to obtain a mixed solution;

[0072] ② Centrifuge the mixed solution obtained in step ① at a rotational speed of 10000r / min for 1 minute, take the supernatant and concentrate the volume to 0.1 times the original volume at 100°C to obtain a concentrated solution;

[0073] ③ The concentrated solution obtained in step ② was dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 3000 to obtain a retentate, which was dried by rotary evaporation to obtain pyrolyzed burdock polysaccharide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com