Spherical tank heat treatment system with multiple burners that can be precisely controlled

A heat treatment system and precise control technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of no automatic control, equipment can not be reused, poor timeliness of control, etc., to achieve timely and effective adjustment, operation and use Convenience and the effect of improving the accuracy of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

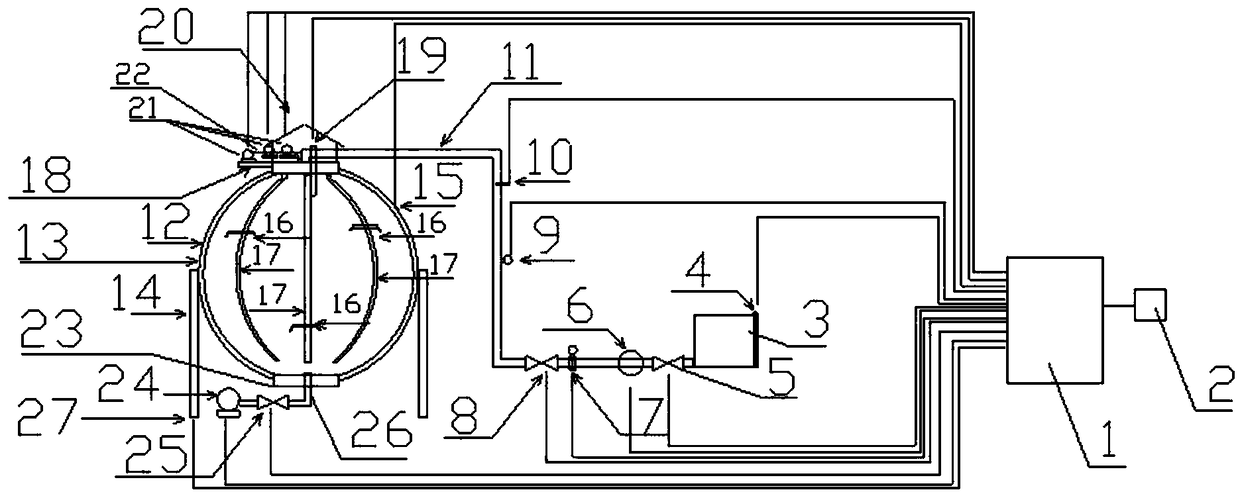

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] as attached figure 1 As shown, the heat treatment system of the spherical tank with multiple burners that can be precisely controlled includes a PLC control system. The PLC control system is connected with external detection and control equipment, receives the detection data transmitted by the external detection equipment, and transmits the control information to the control equipment for execution. corresponding controls;

[0026] In order to realize the object of the present invention, the multi-burner precisely controllable spherical tank heat treatment system of the present invention also includes other hardware facilities. Specifically include:

[0027] It includes an oil tank 3 , which provides oil for the system. There is a liquid level detection transmitter 4 in the oil tank. The oil tank is connected to the burner 16 through the oil delivery pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com