A kind of silver-copper oxide composite electrical contact material and its preparation method and application

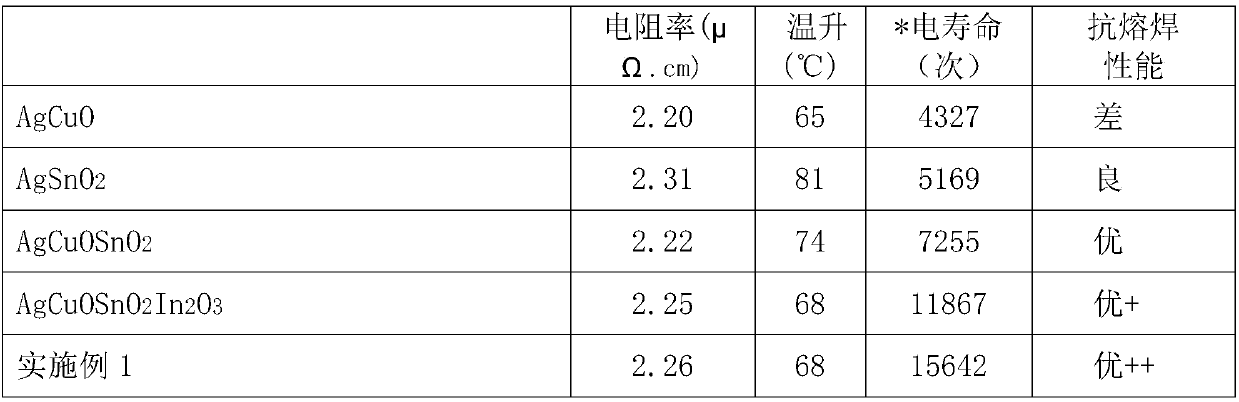

An electrical contact material and copper oxide technology are applied in the field of silver copper oxide composite electrical contact materials and their preparation, which can solve the problems of poor silver tin oxide processing performance, unsatisfactory comprehensive performance, increased surface resistance and the like, and improve comprehensive performance. , shorten the oxidation time, and make up for the effect of increasing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1, a silver-copper oxide composite electrical contact material, comprising the following components: copper oxide content 6%, tin oxide content 3.5%, indium oxide content 0.5%, tellurium oxide content 0.25%, oxide The antimony content is 0.25%, the balance is silver. Its preparation method is:

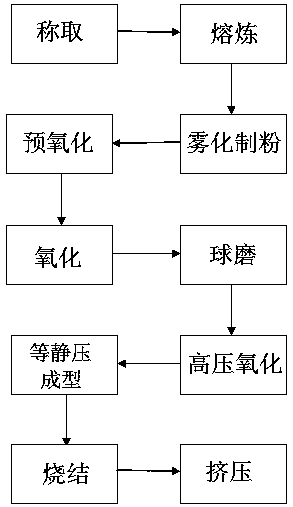

[0031] Step 1, weighing and smelting, calculating the required amount of silver, copper, tin, indium, bismuth and antimony according to the proportion of the silver-copper oxide composite electrical contact material to be prepared, and weighing for later use; then the weighed silver, Copper, tin, indium and additives are smelted into a melt in an intermediate frequency melting furnace;

[0032] Step 2, pulverizing by atomization, performing gas atomization pulverization on the smelted molten metal, and the particle size of the obtained powder is 150-200 mesh;

[0033] Step 3, pre-oxidation, pre-oxidize the powder obtained in step 2; first heat to 200°C, keep warm for 2...

Embodiment 2

[0039] Example 2, a silver-copper oxide composite electrical contact material, comprising the following components: the content of copper oxide is 6%, the content of tin oxide is 5%, the content of indium oxide is 0.2%, the content of bismuth oxide is 0.1%, and the content of oxide The antimony content is 0.1%, and the balance is silver. Its preparation method is:

[0040]Step 1, weighing and smelting, calculating the required amount of silver, copper, tin, indium, bismuth and antimony according to the proportion of the silver-copper oxide composite electrical contact material to be prepared, and weighing for later use; then the weighed silver, Copper, tin, indium and additives are smelted into a melt in an intermediate frequency melting furnace;

[0041] Step 2, atomization powder production, the smelted molten metal is subjected to gas atomization powder production, and the particle size of the obtained powder is 150-320 mesh;

[0042] Step 3, pre-oxidation, pre-oxidize th...

Embodiment 3

[0048] Example 3, a silver-copper oxide composite electrical contact material, comprising the following components: 6% copper oxide, 5.5% tin oxide, 0.2% indium oxide, 0.2% tellurium oxide, and The amount is silver. Its preparation method is:

[0049] Step 1, weighing and smelting, calculating the required amount of silver, copper, tin, indium, bismuth and antimony according to the proportion of the silver-copper oxide composite electrical contact material to be prepared, and weighing for later use; then the weighed silver, Copper, tin, indium and additives are smelted into a melt in an intermediate frequency melting furnace;

[0050] Step 2, atomization powder production, the smelted molten metal is subjected to gas atomization powder production, and the particle size of the obtained powder is 150-320 mesh;

[0051] Step 3, pre-oxidation, pre-oxidize the powder obtained in step 2; first heat to 200°C, keep it warm for 1h, then raise the temperature to 500°C, keep it warm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com