Wax removal method for crude oil well

A technology for oil wells and crude oil, applied in the field of wax removal, can solve the problems of reduced circulation channels of crude oil, blockage of oil pipes, high wax content, etc., and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as Figure 1-Figure 4 Shown, the present invention is used for the wax removal method of crude oil well, comprises the steps:

[0034] Step A installation: fix the winch 11 next to the oil well, fix the fixed wheel 13 above the oil well inlet, connect one end of the wire rope 12 to the winch 11, and connect the other end of the wire rope 12 to one end of the connecting shaft 1 after bypassing the fixed wheel 13;

[0035] Step B wax scraping: start the winch 11, lengthen the wire rope 12, so that the wax removal assembly falls along the diameter of the oil well;

[0036] Simultaneously start the driving device, make the scraper assembly go around the connecting shaft 1, and scrape off the wax layer on the well wall;

[0037] Step C Exit: Start the winch 11, shorten the wire rope 12, and withdraw the wax removal assembly from the oil well.

[0038] Put the wax removal assembly into the oil well that needs wax removal through the winch 11 and other devices, and then...

Embodiment 2

[0040] The present invention is based on embodiment 1, and the present invention is further described.

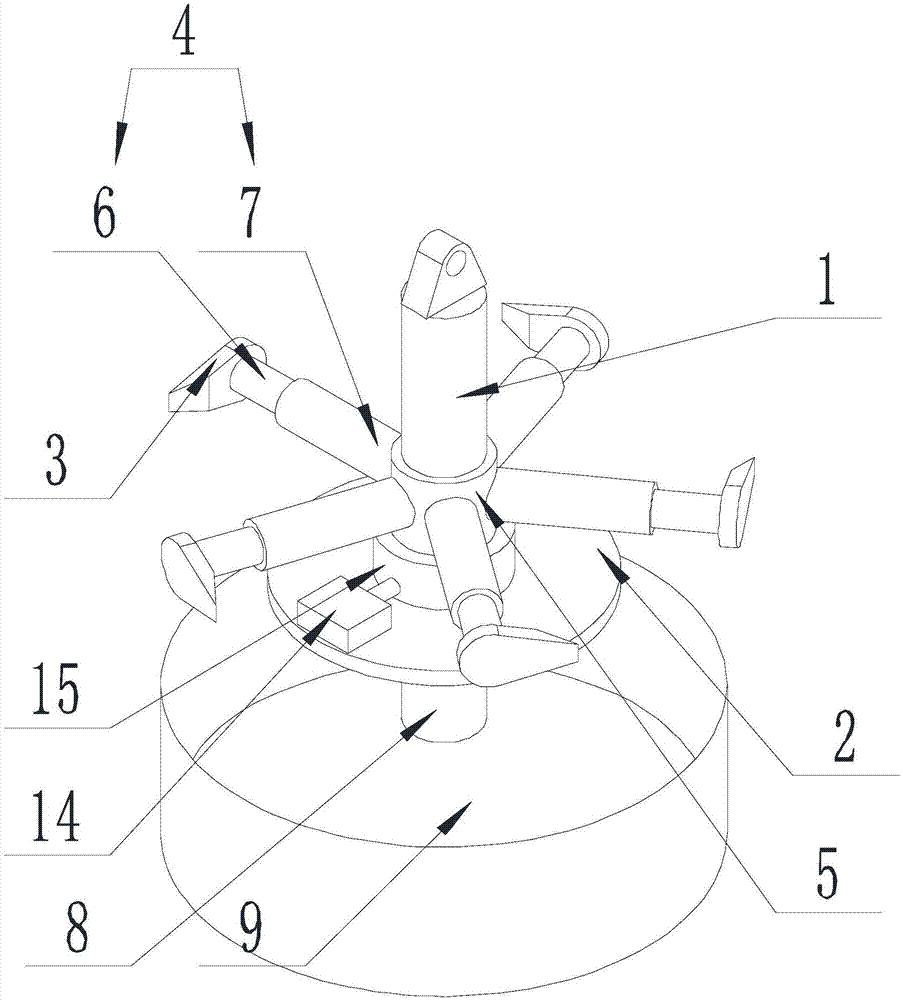

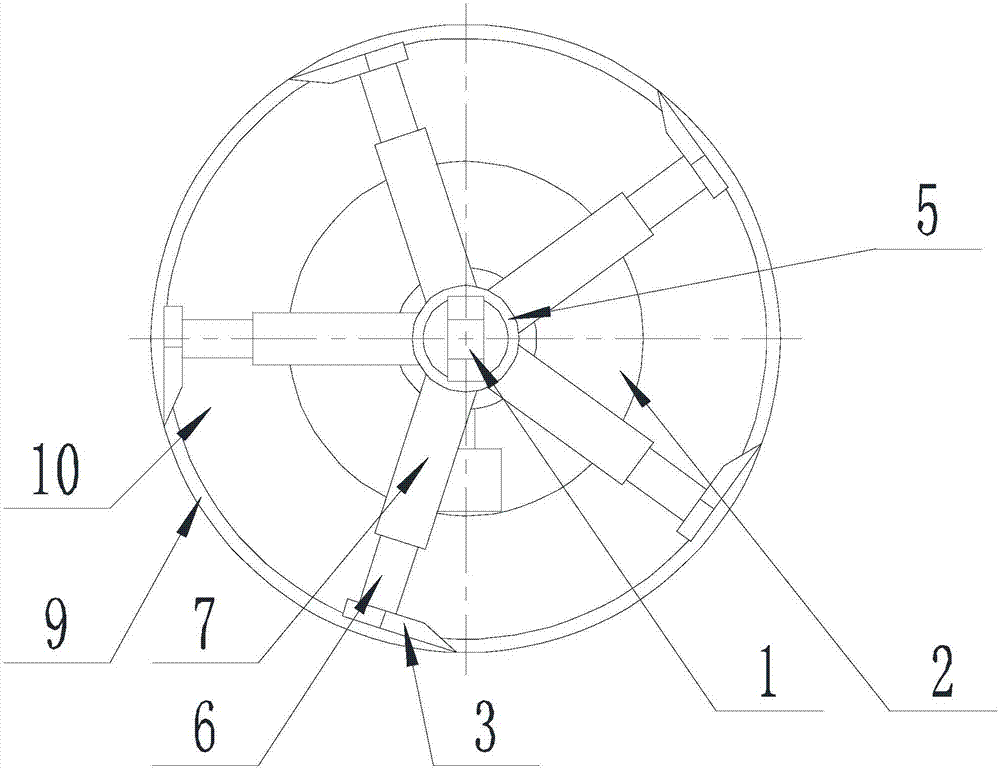

[0041] Such as Figure 1-Figure 4 As shown, the oil well dewaxing device for oil drilling of the present invention, the dewaxing assembly includes a connecting shaft 1, a support plate 2, a scraper assembly and a driving device, one end of the connecting shaft 1 is connected to the suspension device, and the connecting shaft 1 The other end is connected with the support plate 2, the drive device is located on the upper surface of the support plate 2, and connected with the scraper assembly, the drive device drives the scraper assembly to rotate along the axis of the connecting shaft 1.

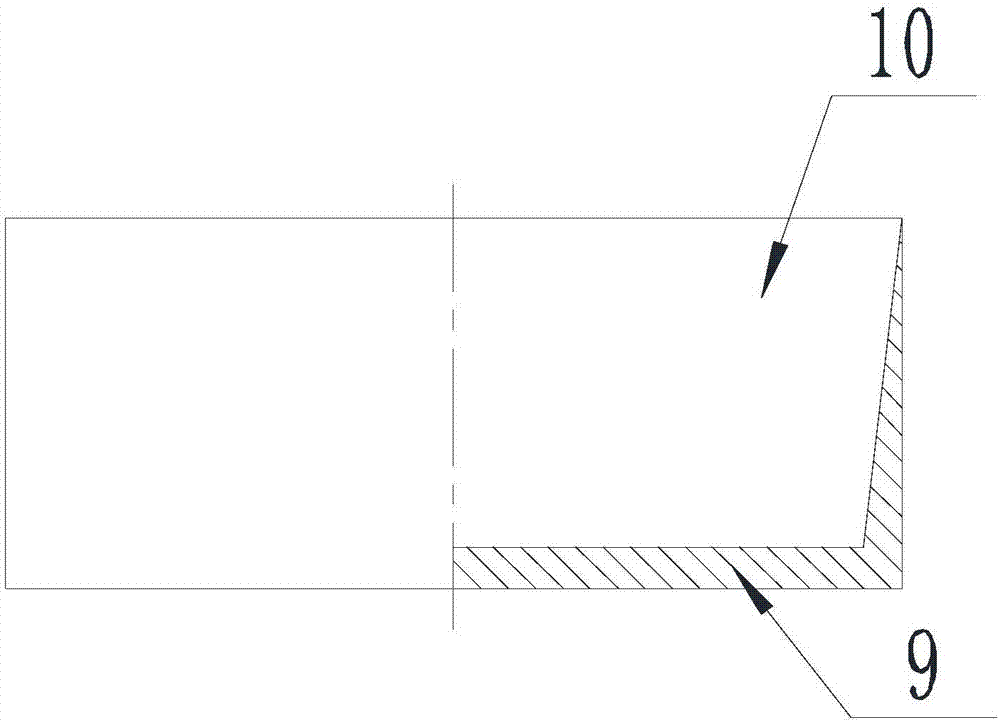

[0042] Further, the scraper assembly includes a connected scraper 3, a connecting rod 4 and a drum 5, one end of the connecting rod 4 is connected to the scraper 3, the blade of the scraper 3 is parallel to the axis of the drum 5, and the connection The other end of the rod 4 is connected ...

Embodiment 3

[0048] The present invention further explains the drive device on the basis of Embodiment 1.

[0049] Such as Figure 1-Figure 4 As shown, the oil well wax removal device for oil drilling of the present invention, the drive device includes a motor 14 and a gear 15, the motor 14 drives the gear 15 to rotate through a reducer, and the gear is sleeved on the drum 5 and drives Drum 5 rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com