Induced blasting and anti-reflection grouting composite anchor for liquid carbon dioxide

A technology of liquid carbon dioxide and composite bolts, which is applied in the direction of installation of bolts, gas discharge, mining fluids, etc., can solve the problems of increasing the range of surrounding rock fissures, and achieve the effects of expanding the range of fissures, improving the effect, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

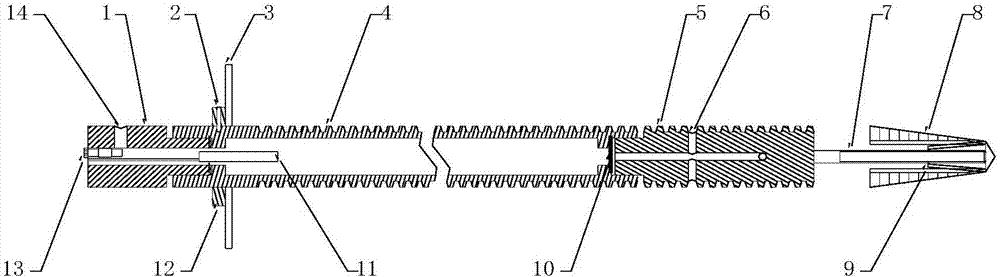

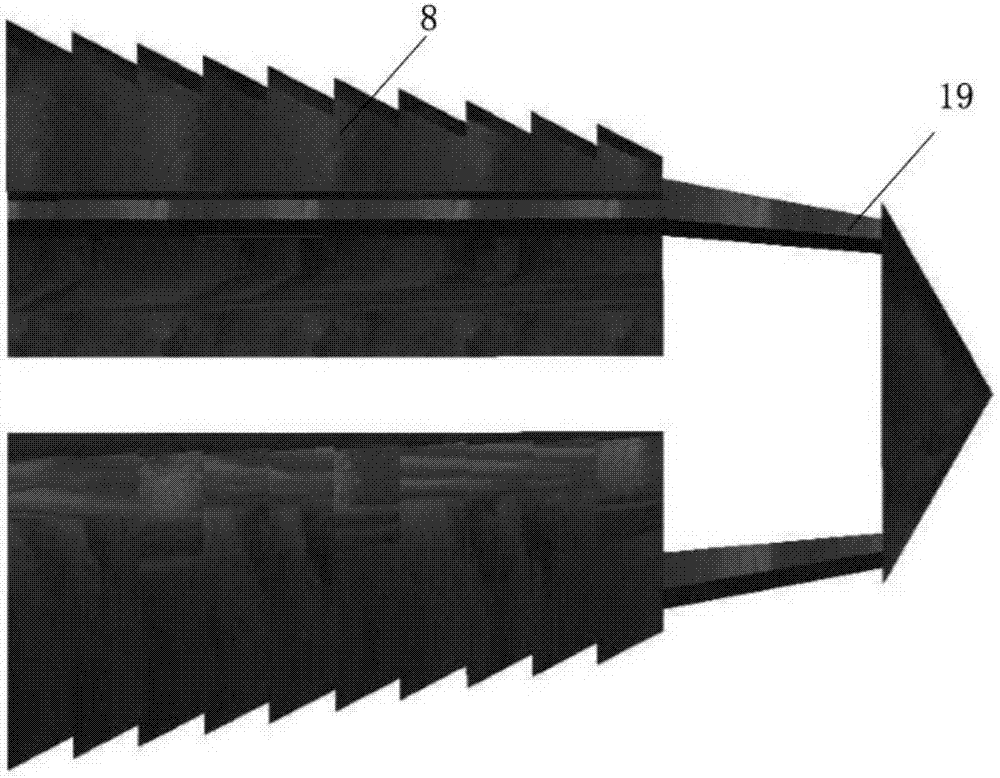

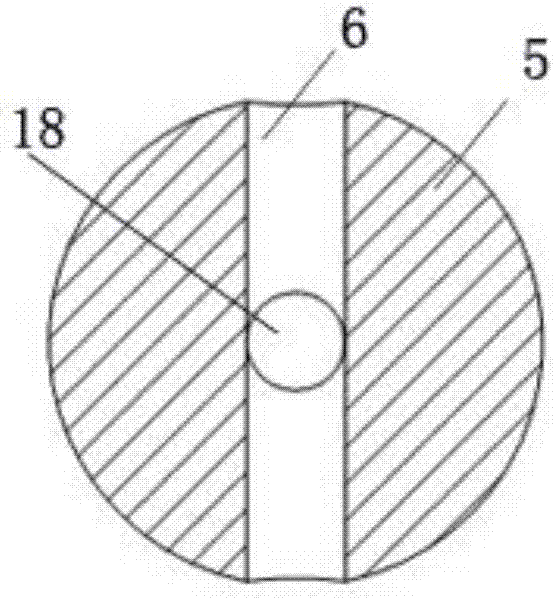

[0025] Such as Figure 1-Figure 5 As shown, a liquid carbon dioxide blasting anti-reflection grouting composite anchor includes an anchor body and an expansion shell anchor head. The anchor body includes a liquid storage pipe 4 and an energy discharge head 5 fixedly connected to the front end of the liquid storage pipe 4 And the filling head 1 that is detachably connected to the rear end of the liquid storage pipe 4, the discharge head 5 is provided with a release pipeline 18 that communicates with the inner cavity of the liquid storage pipe 4, and the outer wall is provided with a drain that passes through the release pipeline. Air holes 6; an energy-dissipating piece 10 is provided between the inner cavity of the liquid storage tube and the release line 18; specifically, the energy-dissipating head 5 rotates in the liquid storage tube 4 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com