Air compression system and control method

A technology for compressing air and a control method, which is applied in the field of compressors, and can solve problems such as the inability to calculate the working efficiency of the air compressor or the input power ratio k in real time, increase the energy consumption of the air supply pressure of the air compressor, and the inability to calculate the start-stop operation, etc. Achieve automatic start and stop, improve operating efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

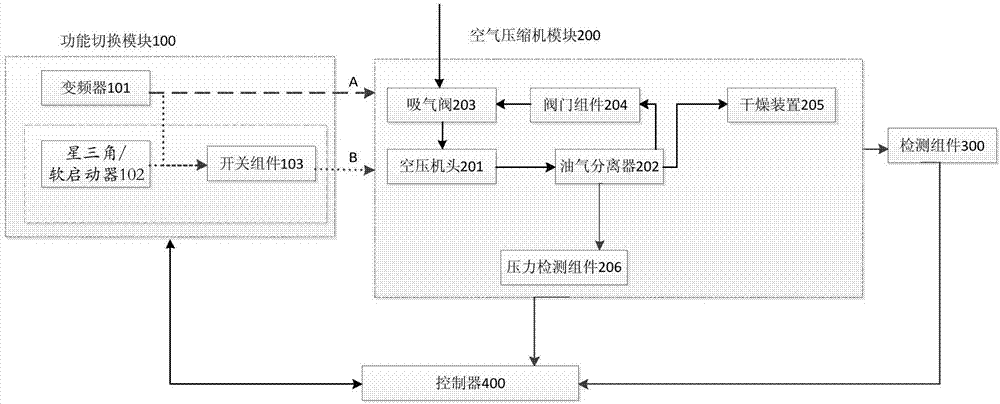

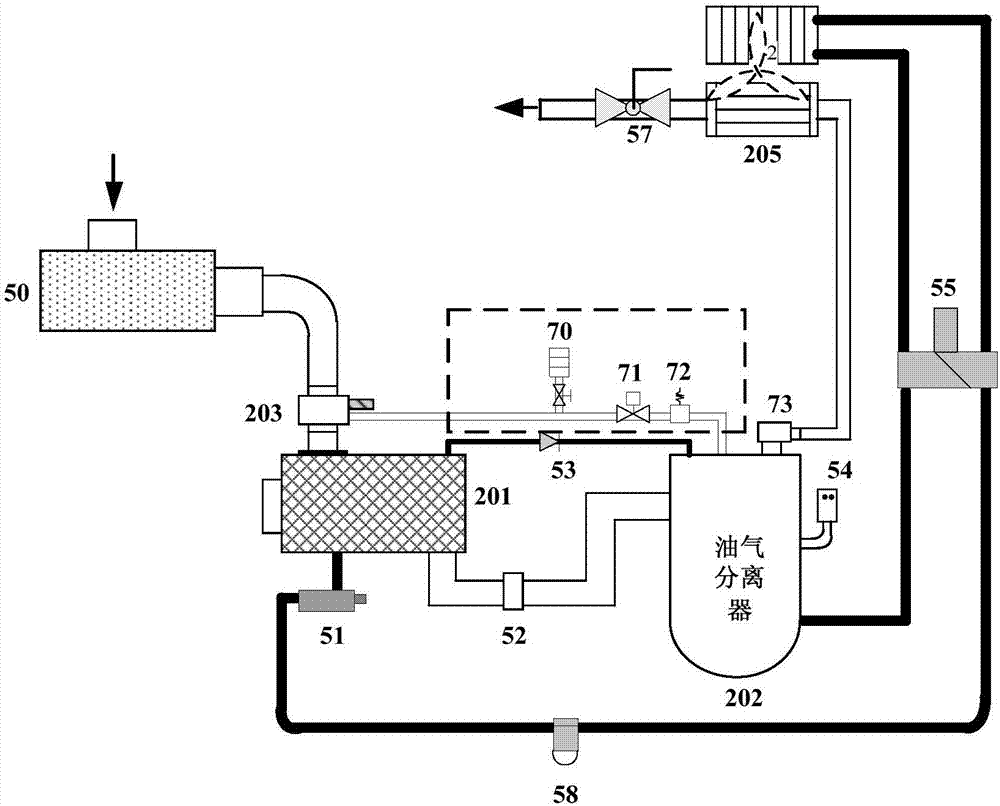

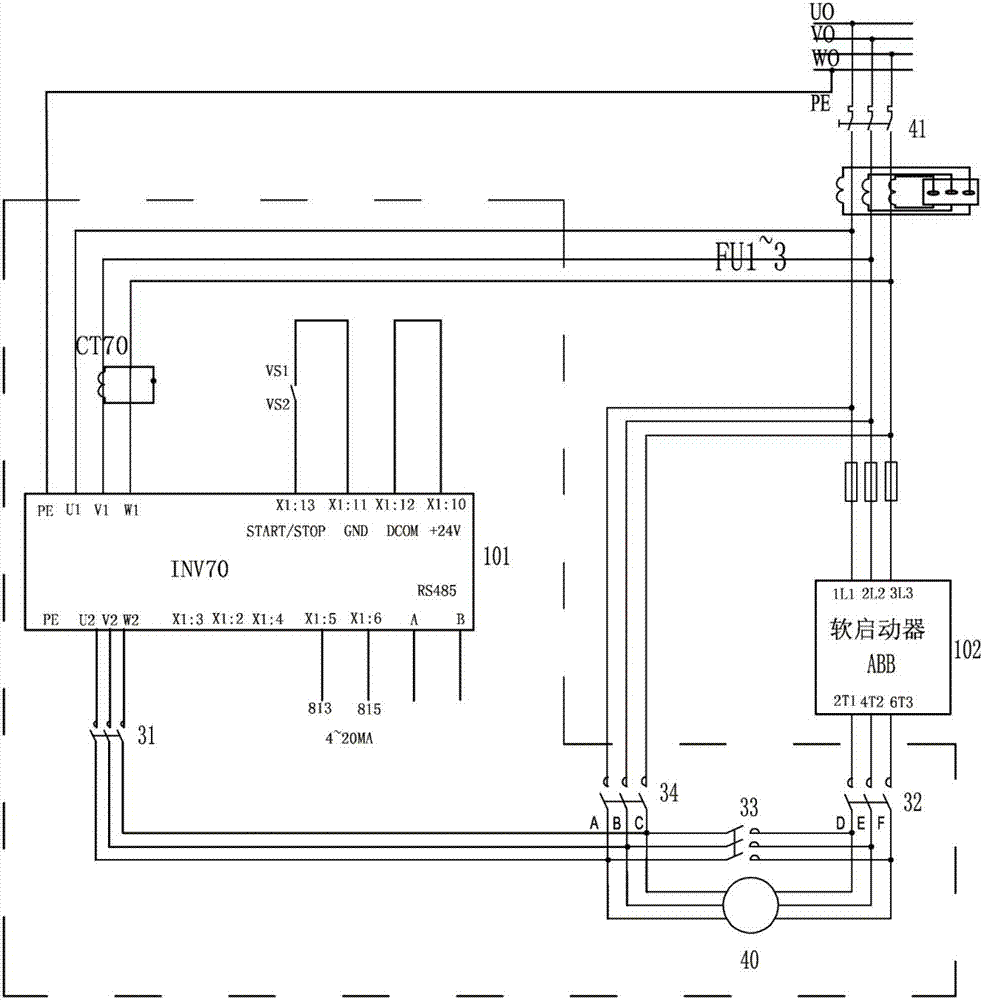

[0032] The embodiment of the present invention provides a compressed air system that participates in figure 1 , the system changes the electric drive mode of the air compressor, from the power frequency star-delta / soft starter control to the frequency converter control, which improves the working efficiency of the air compressor. The compressed air system specifically includes: a function switching module 100, Air compressor module 200 , detection assembly 300 and controller 400 .

[0033] The function switching module 100 is connected to the air compressor module 200 and the controller 400, and is used to change the starting mode of the air compressor, so that the air compressor can be switched between industrial frequency and variable frequency control;

[0034] The air compressor module 200 is respectively connected to the function switching module 100, the detection component 300 and the controller 400 for providing compressed air;

[0035] The detection component 300 is ...

Embodiment 2

[0061] The embodiment of the present invention provides a compressed air control method, which is suitable for the compressed air system described in Embodiment 1, and specifically includes the following methods:

[0062] Method 1. Find the pressure with the highest efficiency within the required pressure range, and assign this value to the PID to control the action of the air compressor. Refer to Figure 4 , the specific control method is divided into the following steps:

[0063] Step S31, install equipment for each air compressor (power frequency and variable frequency) - power collection module 80, flow meter 30, temperature and humidity sensor 35 of suction environment, discharge temperature sensor 10 and discharge pressure sensor 20, The installed sensor data is collected by the air compressor controller 400 to calculate the real-time working efficiency of each air compressor.

[0064] Step S32, calculating the working efficiency of the air compressor

[0065] The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com