Method for controlling continuous casting machine fan-shaped section without displacement sensor

A continuous casting machine segment and displacement sensor technology, which is applied in the field of iron and steel smelting, can solve problems such as production interruption and thermal shutdown, and achieve the effect of reducing failures, reducing equipment failures, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

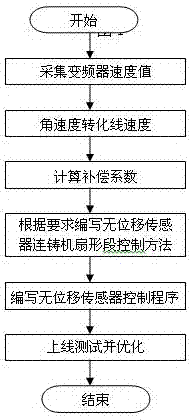

[0019] A method for controlling a segment of a continuous casting machine without a displacement sensor. When the displacement sensor of the segment fails, the speed of the driving roller is used instead of the displacement sensor for control; the method includes the following steps:

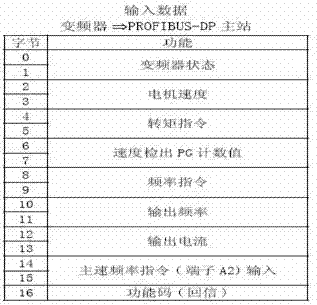

[0020] a Collect the speed value of the frequency converter, the communication between PLC and transmission frequency converter of sector control adopts industrial field bus Profibus-DP, and PLC obtains the speed of frequency converter by reading the state of frequency converter, and this speed is the speed of motor, that is, the sector segment Drive roller angular velocity;

[0021] b Convert the angular velocity of the driving roller of the fan section to the linear velocity, and the calculation is completed by the transmission ratio of the reducer, the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com