Method for preparing adjustable broadband anti-reflection coated glass by solution chemistry

A technology of anti-reflection and anti-reflection and coated glass, which is applied in the direction of coating, etc., can solve the problems of unsuitable for large substrate coating, film layer damage, high equipment cost, etc., and achieve excellent resistance to ultrasonic cleaning, strong film adhesion, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: have the preparation of high refractive index coating solution

[0041] 80 grams of Al(NO 3 ) 3 9H 2 Dissolve O in 210 grams of deionized water, add 210 grams of ethanol and 0.5 grams of German BASF (Koning) water-based paint wetting agent Hydropalat 875, and stir evenly to obtain solution a.

Embodiment 2

[0042] Embodiment 2: have the preparation of coating liquid of low refractive index

[0043] 15 g CH 3 Si(OCH 3 ) 3 and 10 grams (CH 3 ) 2 Si(OCH 3 ) 2 Dissolve in 370 g of absolute ethanol, add a mixed solution of 1.0 g of 70 wt% nitric acid and 10 g of deionized water, and stir for 5 hours to obtain solution b.

Embodiment 3

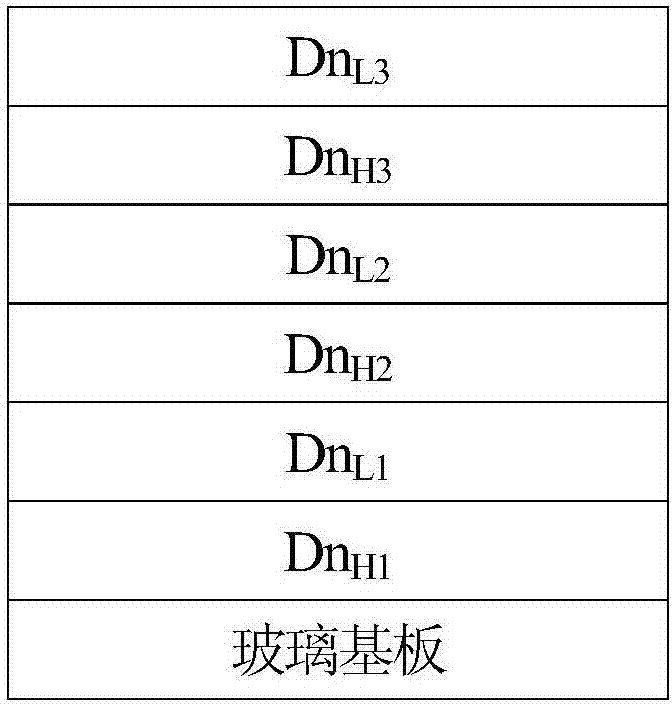

[0044] Embodiment 3: Pulling method prepares anti-reflection and anti-reflection film

[0045] Put solution a in a 500ml beaker and put it into a pulling machine, immerse the cleaned and dried 1.8×70×150 mm glass substrate in solution a, pull it at a speed of 2.5 mm per second, and then heat it in an oven to Keep at 350° C. for 30 minutes to obtain the first coating with a high refractive index. Solution b is placed in a 500ml beaker and placed in a pulling machine, the glass substrate plated with solution a and cured is immersed in solution b, pulled at a speed of 2.5mm per second, and then heated to 350°C in an oven to maintain After 30 minutes, the anti-reflection and anti-reflection coating is obtained. The thickness of the film layer is 80 nanometers for the first layer and 125 nanometers for the second layer.

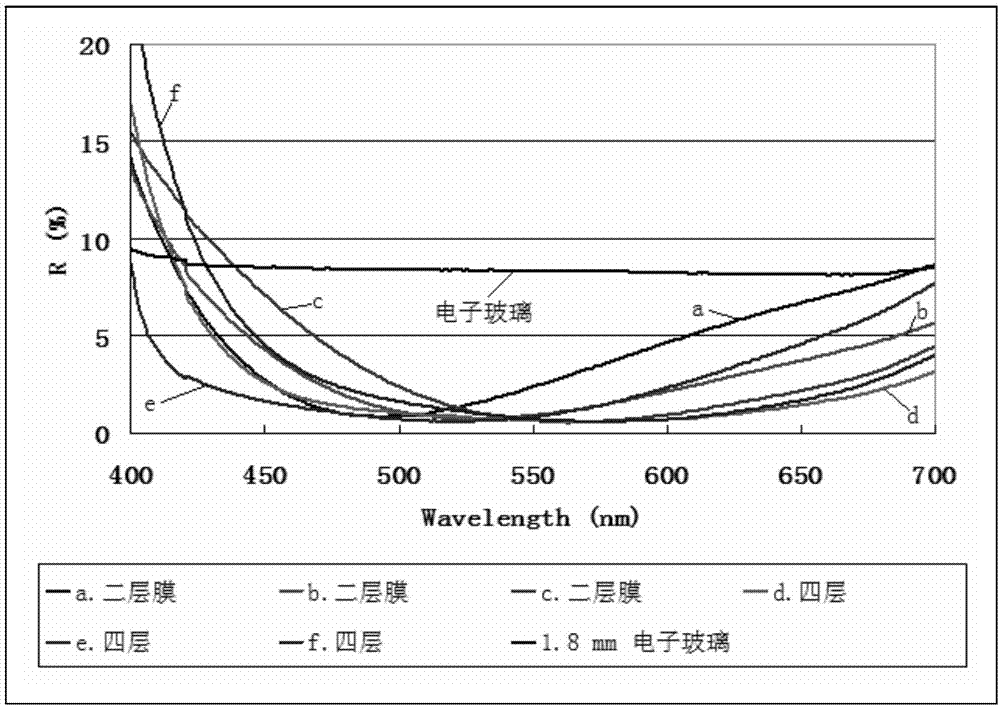

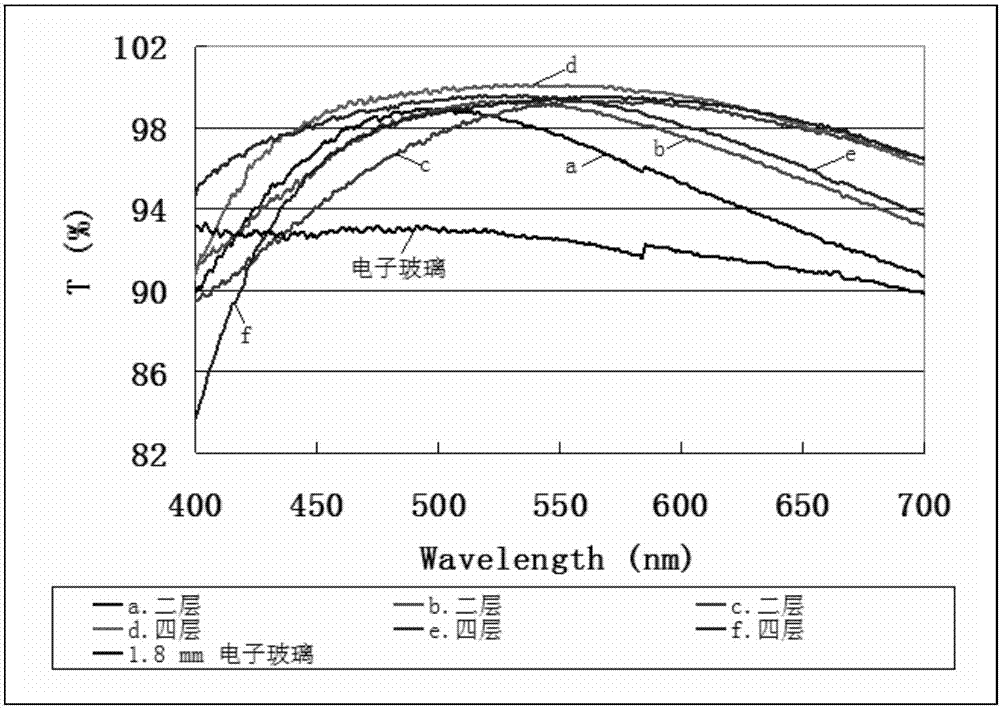

[0046] Referring to the above method, coating solutions using different precursor compounds can be prepared, and non-conductive anti-reflection and anti-reflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com