Temperature controllable method and system for testing burning behavior of metal material

A technology of metal materials and testing methods, applied in the preparation of test samples, chemical analysis by combustion, etc., can solve problems such as uncontrollable temperature, affecting test accuracy, and failure to meet analysis and evaluation requirements, so as to facilitate operation and experiment The effect of high safety and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

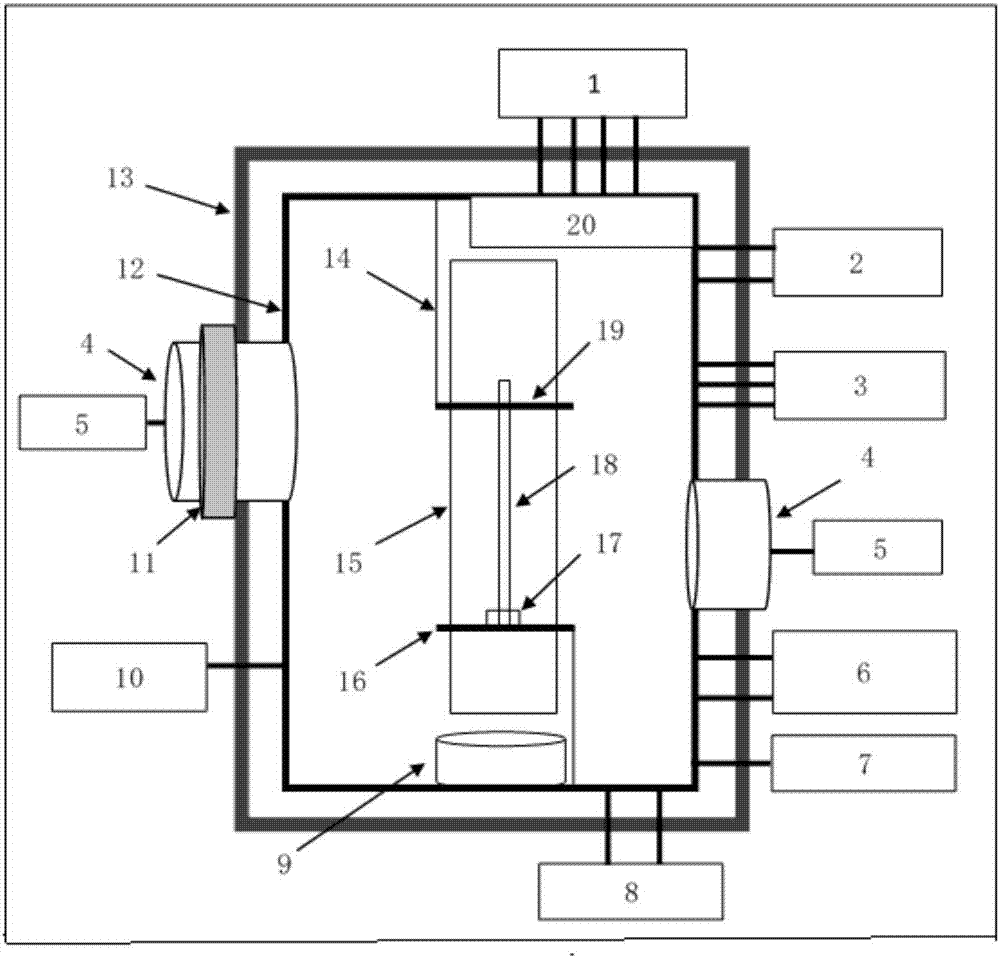

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Superalloy GH4202

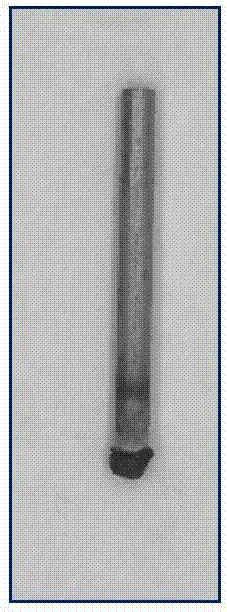

[0039] (1) Make the sample: process the test material into a rod shape, size: diameter Φ3.5mm, length 50mm;

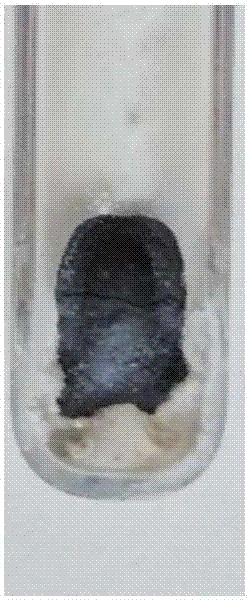

[0040] (2) Add igniter: Process the igniter Mg into a ring size: inner ring Φ3.5mm, outer ring Φ6mm, height 3.5mm; set at one end of the sample

[0041] (3) Install the sample: fix the end without the igniter on the equipment sample fixture, and then install the anti-splash device;

[0042] (4) Vacuuming: After loading the sample in step (2), seal the reaction device, extract the internal air, and the vacuum degree is -1MPa;

[0043] (5) Heating: Heat the entire reaction device to the experimental temperature of 700°C, keep it warm for a certain period of time, and pass the test of the temperature measuring device to ensure that the internal sample reaches the set experimental temperature of 700°C;

[0044] (6) Inflate gas: when the temperature in step (5) rises to the set temperature, open the inflatable device and the gas ci...

Embodiment 2

[0050] Example 2: Superalloy GH3030

[0051] (1) Make the sample: process the test material into a rod shape, size: diameter Φ7mm, length 100mm;

[0052] (2) Add igniter: Process the igniter Al into a ring-shaped size: inner ring Φ7mm, outer ring Φ12mm, height 5mm; set at one end of the sample;

[0053] (3) Install the sample: fix the end without the igniter on the equipment sample fixture, and then install the anti-splash device;

[0054] (4) Vacuuming: After loading the sample in step (2), seal the reaction device, extract the internal air, and the vacuum degree is -1MPa;

[0055] (5) Heating: Heat the entire reaction device to the experimental temperature of 600°C, keep it warm for a certain period of time, and pass the test of the temperature measuring device to ensure that the internal sample reaches the set experimental temperature of 600°C;

[0056] (6) Inflate gas: when the temperature in step (5) rises to the set temperature, open the inflatable device and the gas c...

Embodiment 3

[0062] Embodiment 3: Superalloy GH4169

[0063] (1) Make the sample: process the test material into a rod shape, size: diameter Φ5mm, length 150mm;

[0064] (2) Add igniter: Process the igniter Mg into a ring size: inner ring Φ5mm, outer ring Φ8mm, height 3.5mm; set at one end of the sample

[0065] (3) Install the sample: fix the end without the igniter on the equipment sample fixture, and then install the anti-splash device;

[0066] (4) Vacuuming: After loading the sample in step (2), seal the reaction device, extract the internal air, and the vacuum degree is -1MPa;

[0067] (5) Heating: Heat the entire reaction device to the experimental temperature of 500°C, keep it warm for a certain period of time, and pass the test of the temperature measuring device to ensure that the internal sample reaches the set experimental temperature of 500°C;

[0068] (6) Gas filling: when the temperature in step (5) rises to the set temperature, open the gas charging device and the gas cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com