Outer-cavity-type semiconductor laser structure

A semiconductor and laser technology, applied in the field of external cavity semiconductor laser structure, can solve the problems of reducing volume and weight, and achieve the effect of reducing volume and weight, rational structure layout, and solving complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

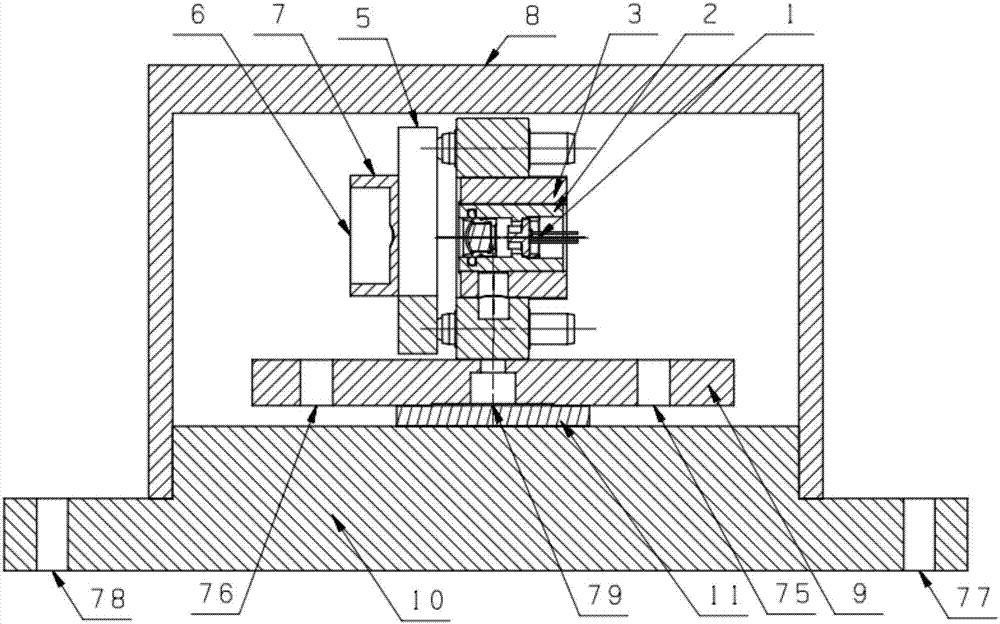

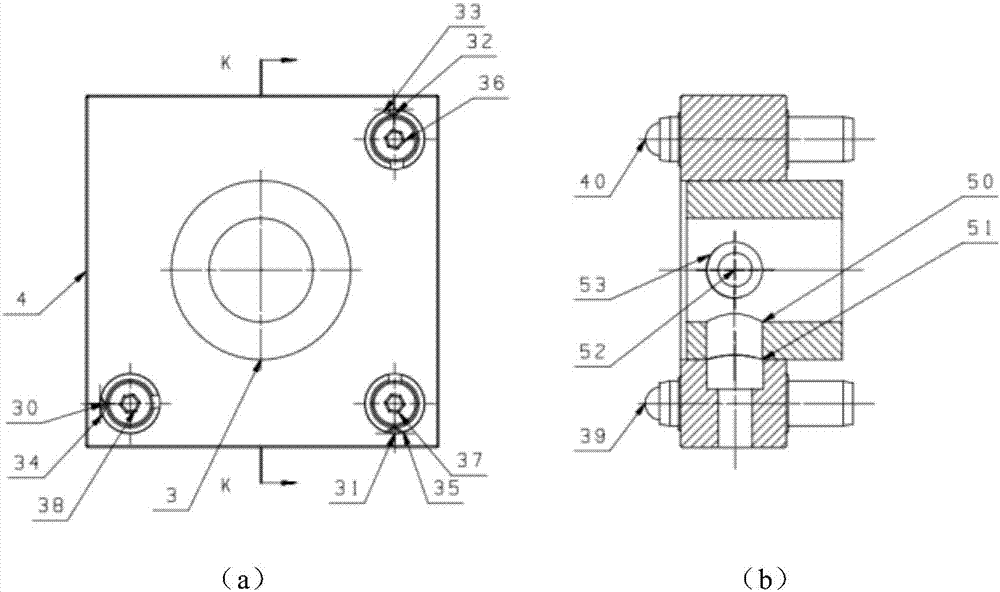

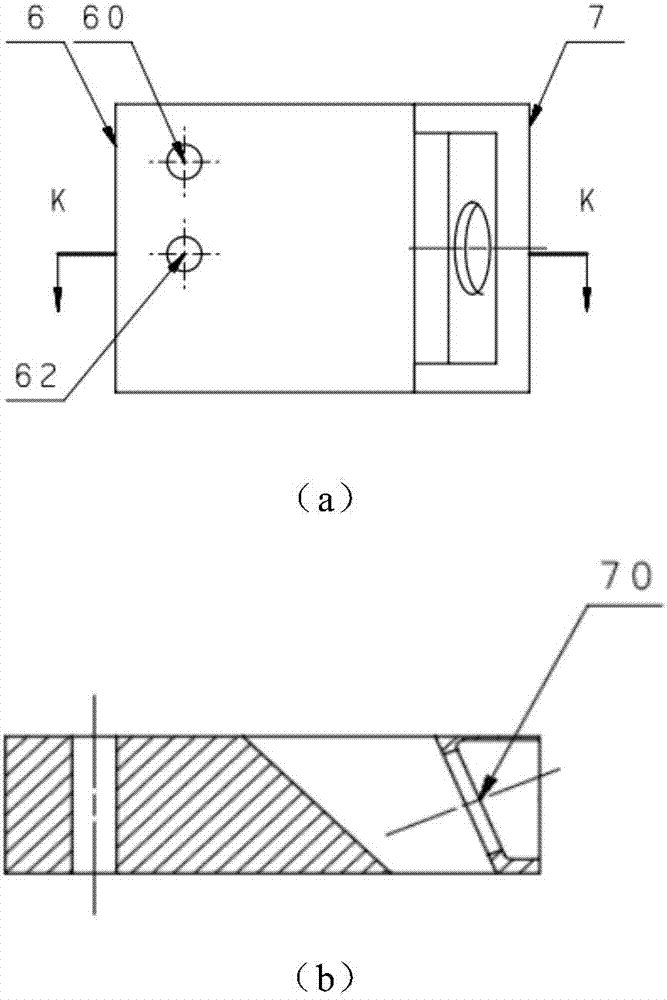

[0026] The concrete implementation structure of a kind of external cavity type semiconductor laser structure of the present invention is as follows figure 1 As shown, it includes laser diode fixing plate 1, lens mounting base 2, sleeve tube 3, adjustable sleeve base 4, L-shaped bracket 5, grating fixing base 6, mirror fixing base 7, fixing screws, locks Clamp nut, shell 8, heat sink 9, base 10, semiconductor refrigerator 11. The lens mounting base 2 is used for the positioning and fixing of the laser diode and the collimating lens on the one hand, and on the other hand, it is installed in the casing 3 through the top thread; The positioning of the base 4 is fixed and compressed by the nut on the heat sink 9; the grating fixing base 6 is used to fix the grating and the free-stroke piezoelectric chip to realize the adjustment of the cavity lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com