Graphite laminates, processes for producing graphite laminates, structural object for heat transport, and rod-shaped heat-transporting object

A manufacturing method, heat transfer technology, applied in the direction of graphite, layered product processing, chemical instruments and methods, etc., can solve problems such as increased heat generation of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach A

[0111] The present invention is a rod-shaped heat transfer body. The thermal conductivity of the rod-shaped heat transfer body measured under the condition that one end of the rod-shaped heat transfer body is in contact with a high-temperature portion and the other end is in contact with a low-temperature portion maintained at 20° C. satisfies the formula (1 )Relationship.

[0112] lambda a / λ b >0.7 Formula (1)

[0113] In formula (1), λ a Indicates the thermal conductivity when the temperature of the above high temperature part is 100°C, λ b Indicates the thermal conductivity when the temperature of the above-mentioned high-temperature portion is 50°C.

[0114] In miniaturized and high-power electronic devices such as smartphones and tablet computers, heat pipes are used as a means of efficiently transferring the heat to a location as far away from the CPU as possible due to the large amount of heat generated by the CPU. Heat pipes can directly connect high-temperature ...

Embodiment approach B

[0171] [B-1. Graphite laminate]

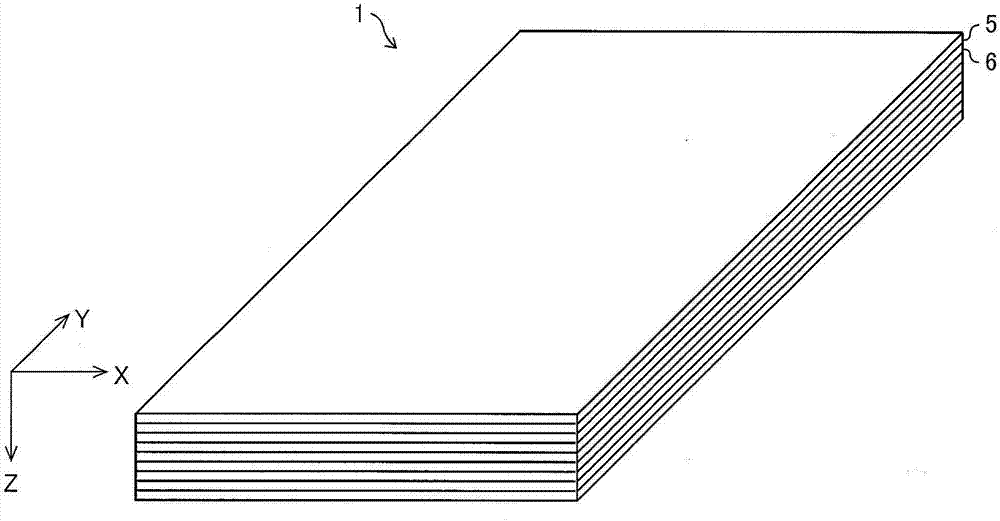

[0172] The graphite laminate of the present embodiment is a graphite laminate including alternately laminated graphite sheets and adhesive layers (or a graphite laminate in which graphite sheets and adhesive layers are alternately laminated). The adhesive layer may contain at least one resin selected from thermoplastic resins and thermosetting resins. In addition, the water absorption rate of the above-mentioned adhesive layer may be 2% or less, and the thickness may be less than 15 μm. The number of laminations of the graphite sheets included in the graphite laminate may be 3 or more. The graphite laminated body may be obtained by further compressing a laminate formed by alternately laminating the above-mentioned graphite sheet and the above-mentioned adhesive layer. The thickness of the above-mentioned adhesive layer means the thickness of the adhesive layer contained in the graphite laminated body in the finished state, not the thickness ...

Embodiment approach C

[0367] [C-1. Graphite laminate]

[0368] The graphite laminate of the present embodiment is a graphite laminate containing alternately laminated graphite sheets and an adhesive layer (or a graphite laminate formed by alternately laminating graphite sheets and adhesive layers), wherein the material for the adhesive layer The adhesive layer material or the adhesive layer contains at least one of thermoplastic resin and thermosetting resin.

[0369] The number of stacked graphite sheets contained in the graphite laminate is three or more. As described below, the graphite laminate is obtained by heating and pressurizing a laminate in which graphite sheets and adhesive layer materials are alternately laminated.

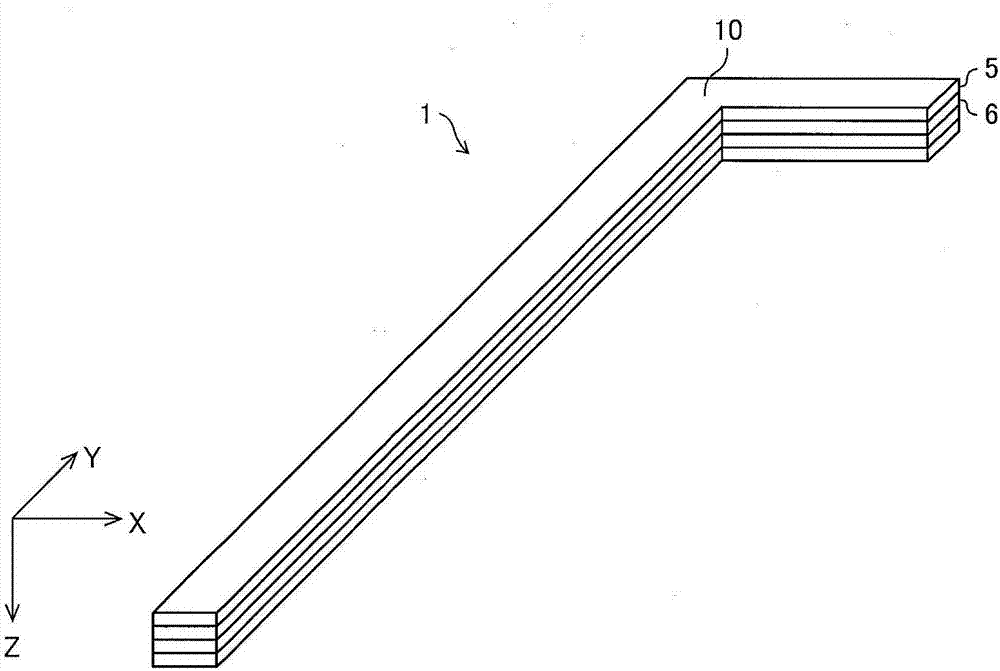

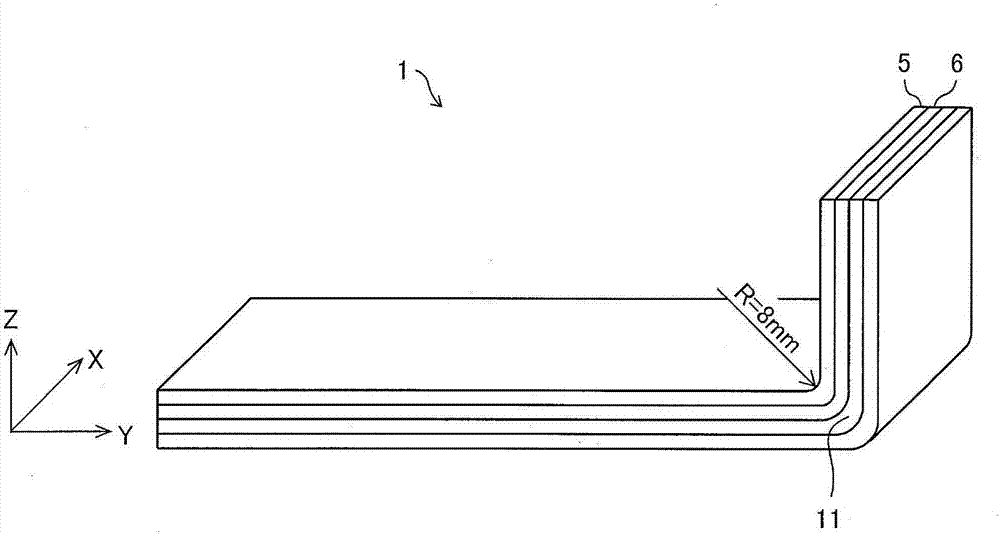

[0370] In addition, the graphite laminate of the present invention may have a shape in which at least one bent portion thereof is bent. The graphite laminate may be formed by bending the laminate, or may be formed by bending the graphite laminate.

[0371] Hereinafter, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com