Method for preventing aluminum alloy overlap welding grain boundary liquefying cracks through friction stir processing

A technology of friction stir and liquefaction cracking, applied in the field of material processing, can solve the problems of reducing production efficiency and complicated process, and achieve the effects of improved crack resistance, low consumption frequency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

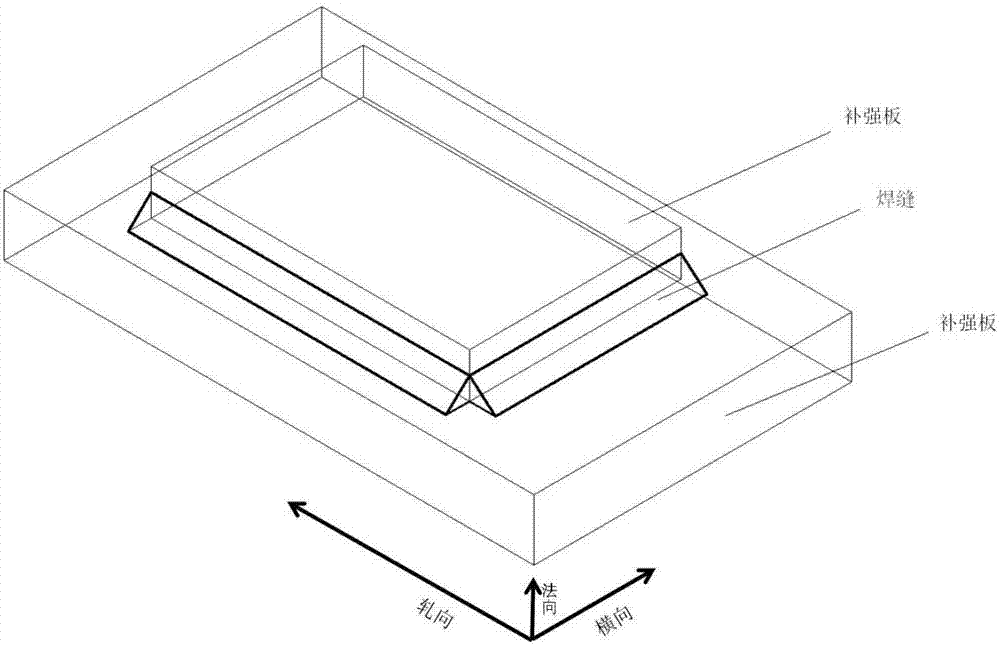

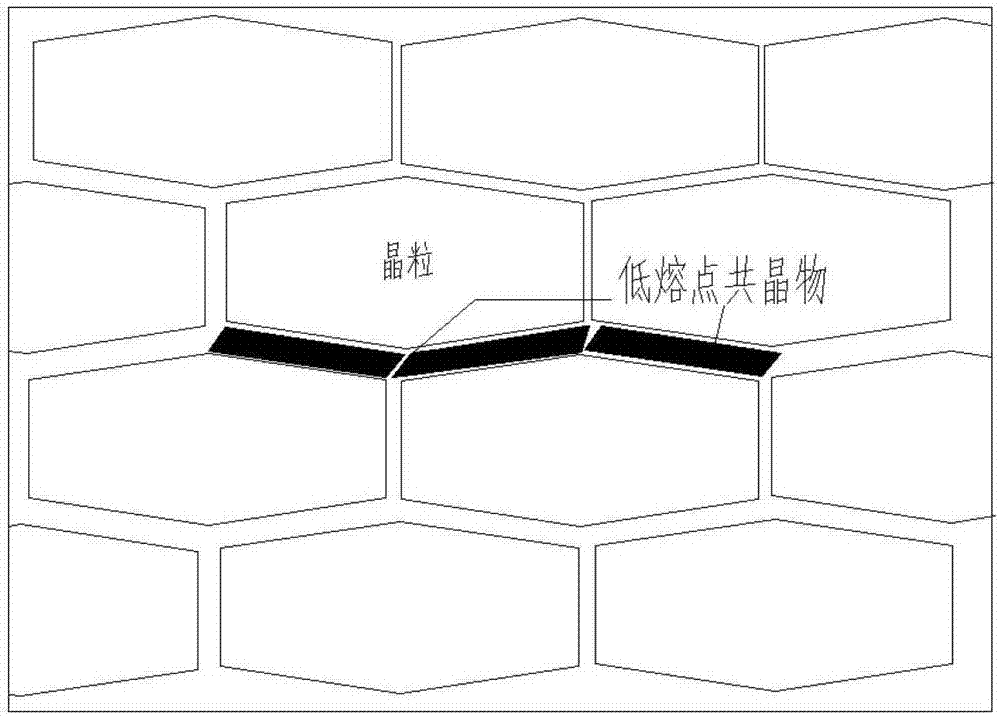

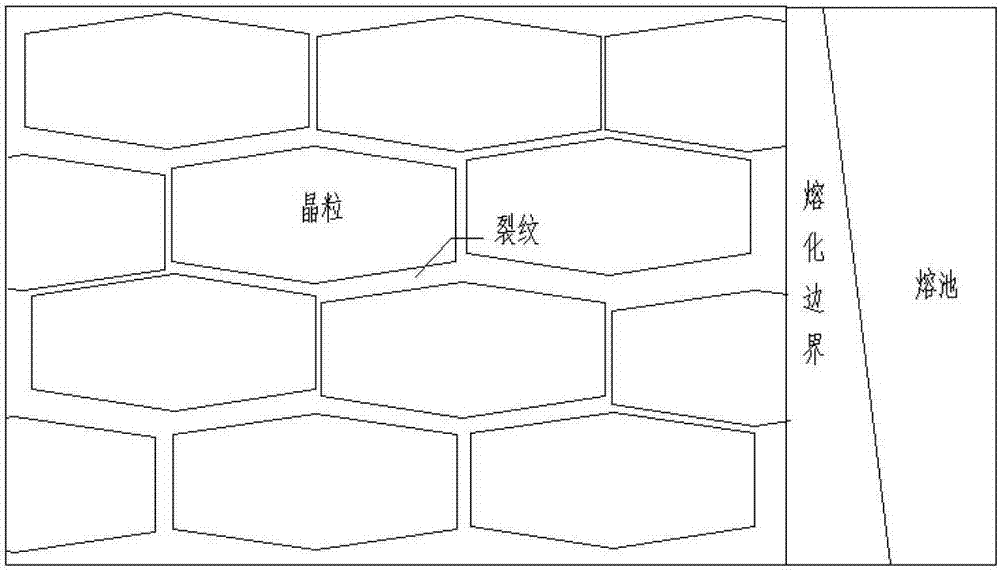

[0032] For 20mm and 9mm thick 7N01-T4 aluminum alloy plates, MIG fillet welding is performed, of which the 20mm plate is the reinforcing plate and the 9mm plate is the bottom plate. During the inspection of MIG fillet weld joints, it was found that there were crack defects in the heat-affected zone of the 20mm thick reinforcing plate near the weld. It is believed that the main reason is that the eutectic MgZn with low melting point is distributed on the grain boundary of this position. 2 phase, and there is a large welding tensile stress at this position. So the 20mm thick 7N01-T4 aluminum alloy plate was subjected to friction stir processing and MIG fillet welding. The surface of the 7N01-T4 aluminum alloy plate is mechanically polished to produce a metallic luster, and the workpiece is fixed on the friction stir process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com