Packaging film, and polymer lithium battery packaged with packaging film

A packaging film, polymer technology, applied in secondary batteries, battery pack parts, applications, etc., can solve problems such as cracking, increased production costs, perforation of aluminum layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The device of the present invention will be further described below in conjunction with the accompanying drawings and examples of implementation. This description is only an illustration of the device of the present invention, not a limitation of the present invention.

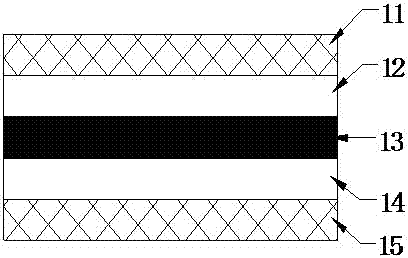

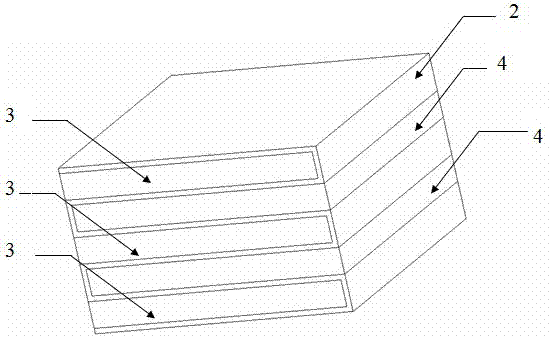

[0019] A packaging film and a polymer lithium battery packaged with the film, comprising an outer protective layer (11), an outer adhesive layer (12), a silicon plastic film (13), an inner adhesive layer (14), a CPP layer (15 ); the polymer lithium battery using the packaging film of the present invention is composed of a separator (2), a negative electrode sheet (3), a positive electrode sheet (4), an electrolyte (5), and the packaging film of the present invention.

[0020] The polymer lithium battery encapsulated by the film is internally composed of positive electrode sheet (4), negative electrode sheet (3), diaphragm (2), electrolyte, etc., and is externally encapsulated with the packaging film of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com