Big-torque self-balance low-speed turbine drilling tool

A turbodrilling tool and self-balancing technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problems of drilling tool face deviation, low drilling efficiency, small output torque, etc., to avoid anti-torque effect, structure Effect of compactness and increased output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

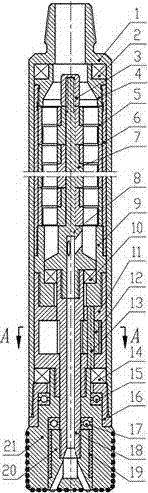

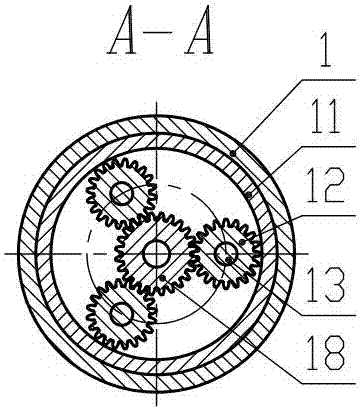

[0012] Such as figure 1 As shown, a high-torque self-balancing low-speed turbo drilling tool of the present invention is composed of an outer shell 1, a self-aligning bearing a2, a nut 3, an upper bearing seat 4, an outer turbine blade combination 5, an inner cylinder body 6, and an inner turbine blade Combination 7, mandrel 8, lower bearing seat 9, self-aligning bearing b10, transmission cylinder 11, speed regulating gear 12, gear shaft 13, self-aligning bearing c14, thrust bearing a15, anti-drop end cover 16, thrust bearing b17, transmission Shaft 18, anti-wear sleeve 19, inner drill bit 20 and outer drill bit 21; its structural features are: the upper end of the outer casing 1 is connected with the upper drill string; Three through holes are evenly arranged in the circumferential direction to communicate with the inner and outer cavity spaces of the mandrel 8; the inner turbine blade assembly 7 is set on the upper stepped shaft of the outer circle of the mandrel 8, the nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com