A pulverized coal decoupling burner and combustion method with enhanced diversion and enrichment

A burner and dense coal powder technology, applied in the direction of combustion methods, burners for burning powder fuel, burners, etc., can solve the problem of reducing the concentration effect of pulverized coal airflow, reducing the service life of burners, and affecting decoupling combustion efficiency problems such as reducing coal segregation and coking, improving the service life of equipment, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following are examples of the present invention, which are only used to explain the present invention and not limit it.

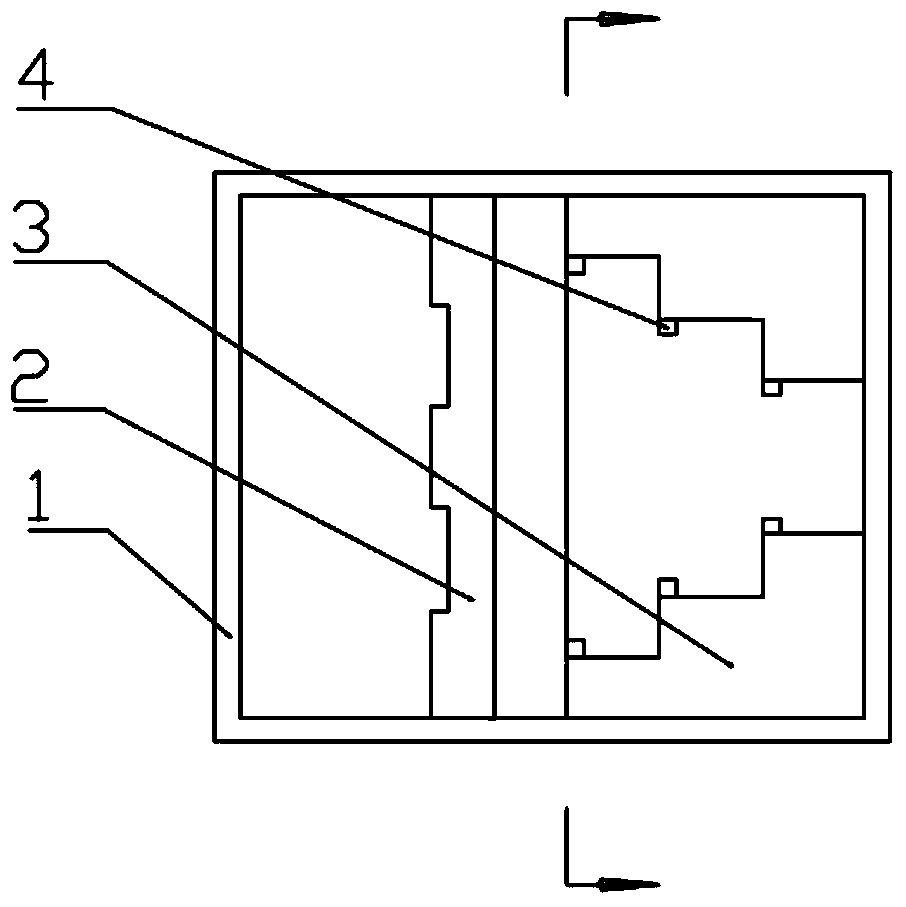

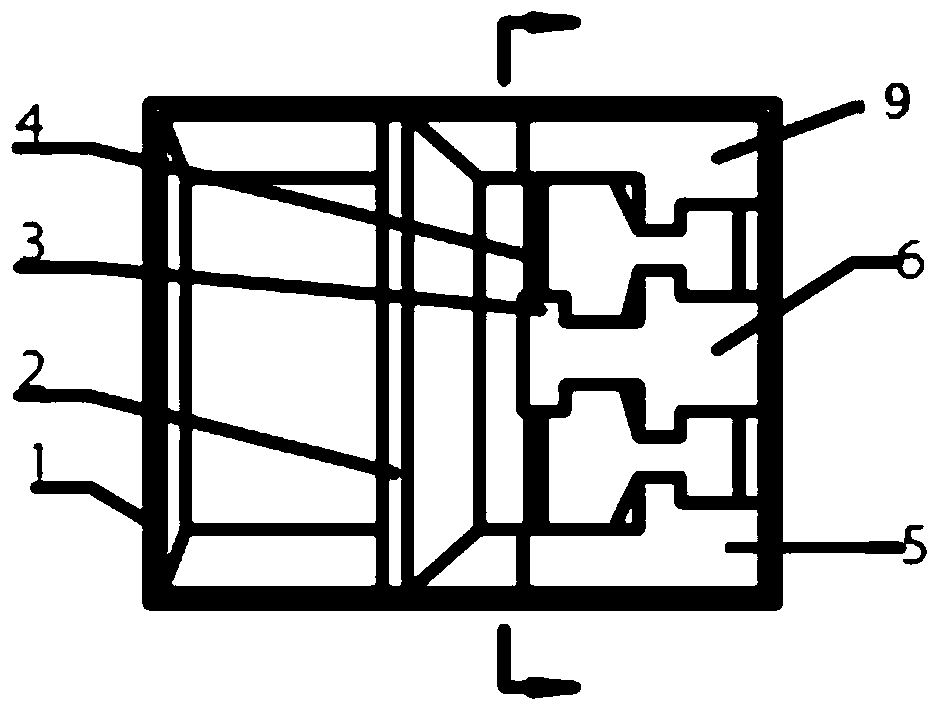

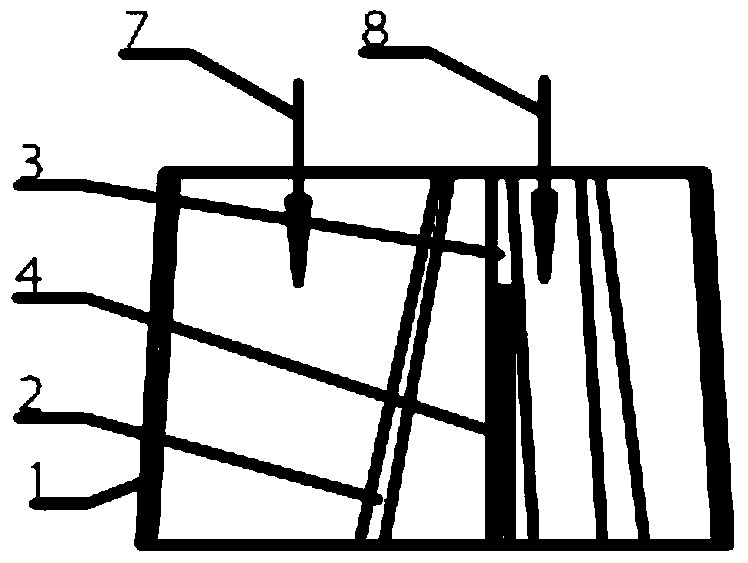

[0049] The present invention provides a pulverized coal decoupling burner with enhanced diversion and enrichment. The burner includes a nozzle 1, a thick-lean diversion plate 2, an upper powder collector flame stabilizer 9, a lower powder collector flame stabilizer and a middle powder collector flame stabilizer 6;

[0050] The thick-lean divider 2 is arranged in the middle of the spout 1, and the upper and lower ends of the thick-thin divider 2 are connected to the outer shell of the spout 1; 7 and two airflow passages of the rich side airflow 8;

[0051] The upper powder-collecting flame stabilizer 9, the lower powder-collecting flame stabilizer 5 and the middle powder-collecting flame stabilizer 6 are located at the passage side of the air flow 8 on the concentrated side; the upper powder-collecting flame stabilizer 9, the lower powder-collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com