Droplet generator and droplet preparation method

A technology of droplet generator and manufacturing method, applied in the direction of instruments, preparation of samples for testing, analysis of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

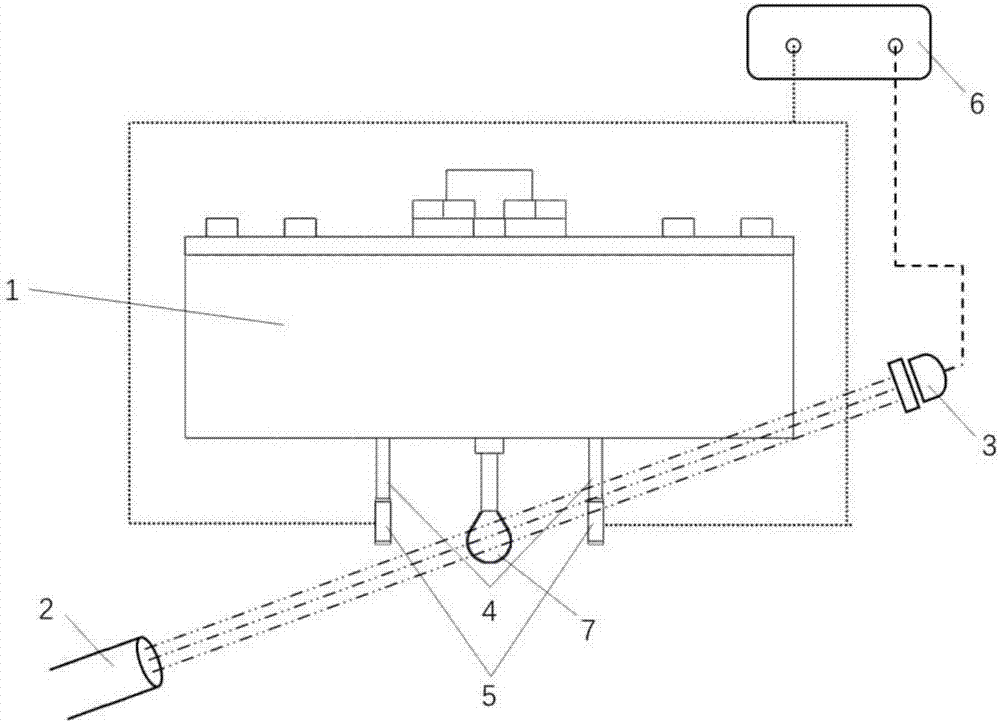

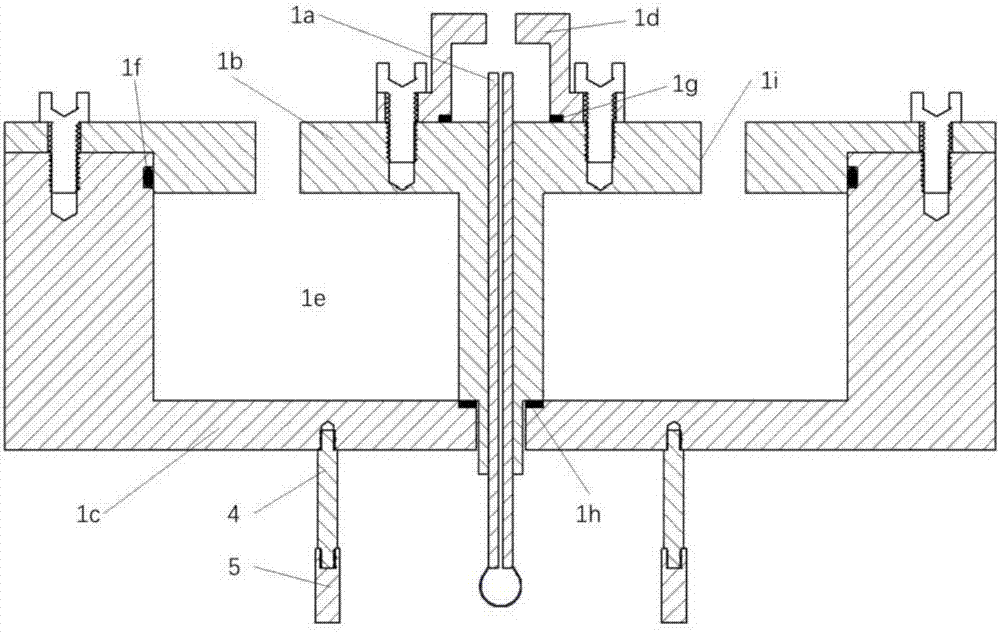

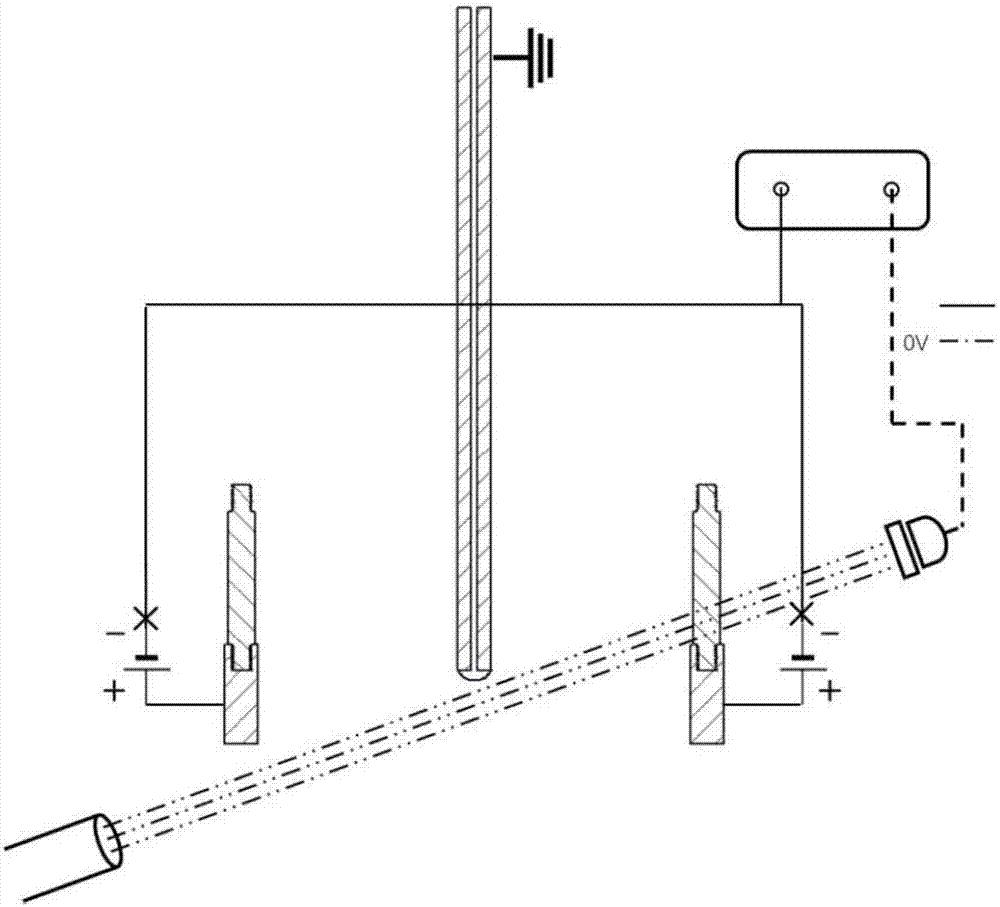

[0036] join figure 1As shown, a droplet generator is disclosed. The droplet generator includes a droplet generator main body 1 , a constant light source 2 , a photodetector 3 , an electrode plate 5 and a pulse high voltage power supply 6 . The droplet generator 1 includes a grounded stainless steel capillary, and a sealed water bath is arranged around the upper part of the stainless steel capillary. The charging properties of the electrode plates 5 are the same after being energized and can be connected to the main body 1 of the droplet generator through the insulating post 4. The electrode plates 5 are placed on both sides of the droplet outlet, and the pulsed high-voltage power supply 6 can be controlled by timing Give the electrode plate a momentary high voltage of kV level as needed. The constant point light source 2 is irradiated at the bottom of the droplet generator main body 1 capillary, that is, the outlet of the suspended droplet, and the constant point light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com