Single-dose hair care hair dye based on walnut green peel pigment and its preparation and use method

A walnut green husk and single-dose technology, which is applied to medical preparations containing active ingredients, pharmaceutical formulas, hair care, etc., can solve the problems that the preparation process is easily affected by the external environment and the dyeing cream is unstable, and achieves short hair dyeing time, The preparation process is simple and the hair dyeing temperature is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh a certain amount of deionized water, heat it to 80°C, add 5% cetearyl alcohol, 5% glycerin, and 2.5% octadecyltrimethylammonium chloride, wait for complete dissolution, and stir mechanically for 30 minutes at a speed of 500 rpm; then lower the temperature to 45°C, add 0.1% vitamin E, 0.5% panthenol, 0.02% citric acid, 1.0% polyquaternium-7 and stir for 25 minutes, then add 20% walnut green skin pigment, stir 5 minutes; add 2.5% ferrous chloride and stir for 10 minutes; increase the stirring speed to 1200 rpm, add 0.3% hydroxyethyl cellulose, and add water to the system and stir for 30 minutes to obtain a single-dose hair dye.

Embodiment 2

[0029] Weigh a certain amount of deionized water, heat it to 80°C, add 6% squalane, 5% glycerin, and 2.5% cetyltrimethylammonium chloride, wait until completely dissolved, stir mechanically for 30 minutes, and rotate at 300 rpm / min; then lower the temperature to 45°C, add 0.1% vitamin E, 0.5% panthenol, 0.02% citric acid, 1.5% polyquaternium-7 and stir for 30 minutes, then add 25% walnut green peel pigment and stir for 10 minutes; Add 1.5% alum and stir for 10 minutes; increase the stirring speed to 800 rpm, add 1.0% hydroxyethyl cellulose, and add water to the system, then stir for 30 minutes to obtain a single-dose hair dye.

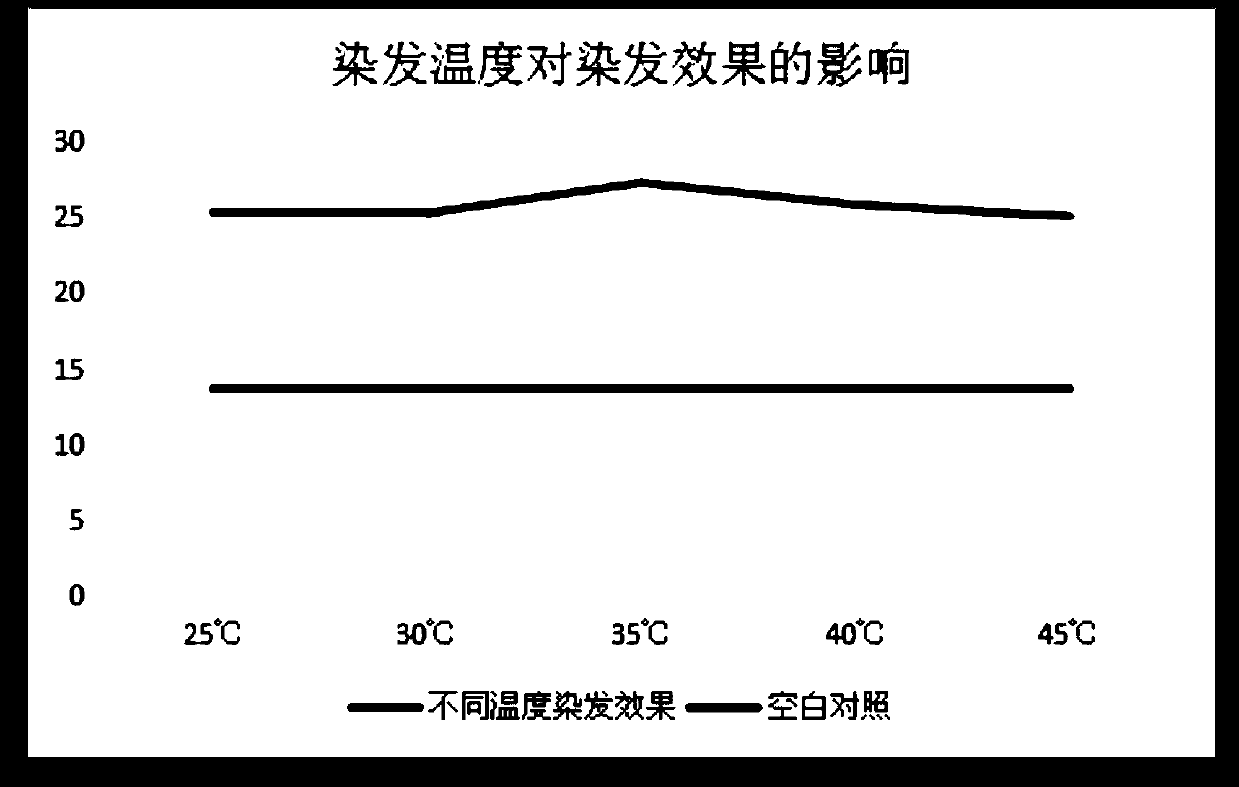

[0030] 2. Comparison test of hair dyeing temperature

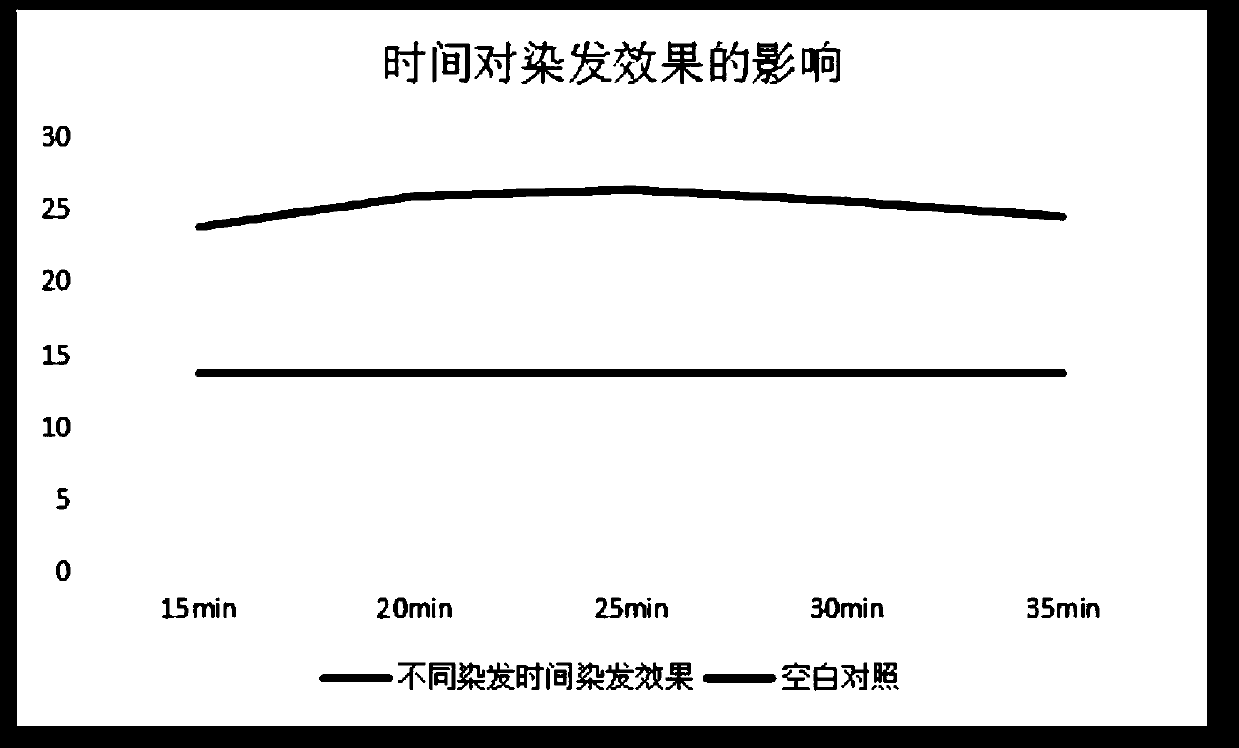

[0031] According to the single-dose hair dye prepared by the above-mentioned preparation method, refer to figure 1 , Dye the white hair strands at a temperature of 40°C. After 30 minutes, the hair dyeing effect has reached the best. Therefore, in actual operation, a hair dyeing temperature of 35-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com