Portal frame type five-freedom-degree abrasive water jet spatial machining mechanical arm

A technology of abrasive water jet and degree of freedom, which is applied in the direction of abrasive jet machine tools, manipulators, abrasives, etc., can solve the problems of poor flexibility and achieve the effect of improving efficiency, improving flexibility and cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

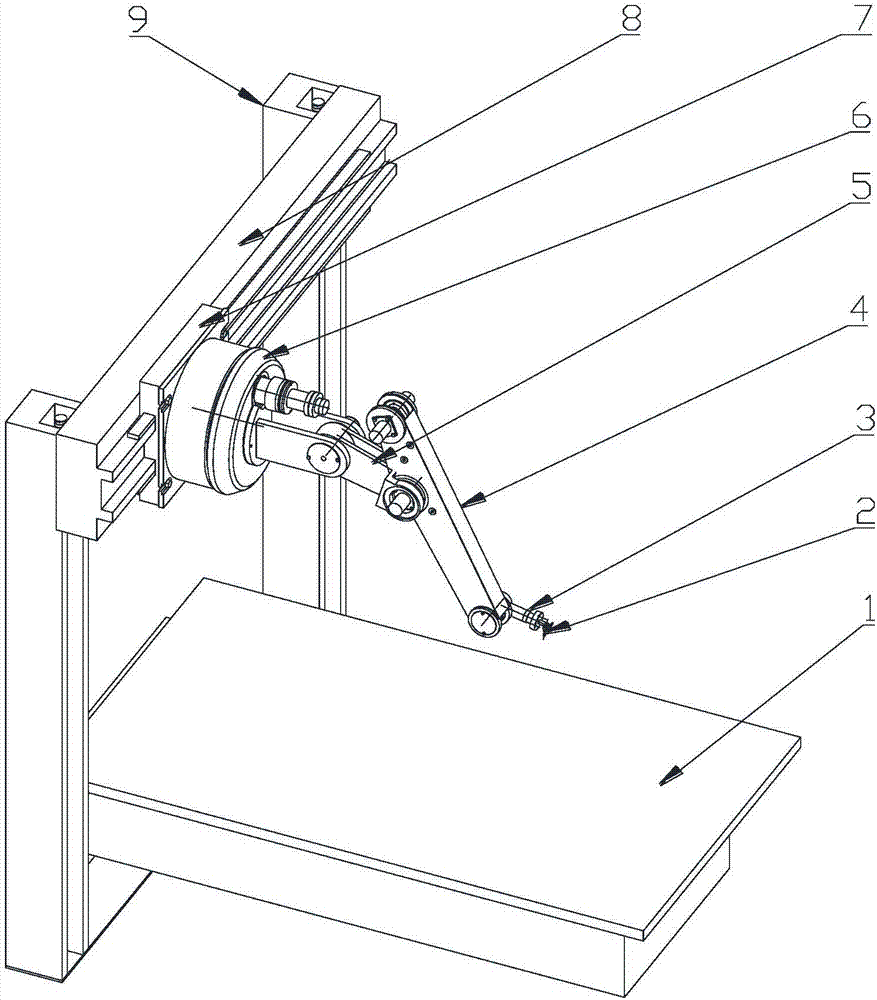

[0012] According to the accompanying drawings, the present invention provides a gantry-type five-degree-of-freedom abrasive water-jet space processing manipulator, which includes a gantry-type worktable 1, an abrasive water-jet nozzle 2, and 3. Forearm 4, large arm 5, machine base 6, slider 7, gantry beam 8, gantry column 9; the gantry column 9 is placed on both sides of the gantry workbench 1, and the gantry beam 8 can move up and down along the gantry column 9. Described gantry beam 8 is provided with guide rail, and slide block 7 is connected on the guide rail; Described machine base 6 and slide block 7 are fixed, and machine base 6 can move left and right along gantry beam 8 through slide block 7; Said machine base The waist of the arm 6 can perform rotary motion; the rear end of the boom 5 is connected to the machine base 6 and can perform pitching motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com