Method and system for improving air permeability of iron ore sintering mixture

A technology for sintering mixtures and iron ore, which is applied in the field of iron ore sintering, can solve the problems of poor air permeability of the material layer, low sintering speed, and poor physical and chemical properties, so as to improve air permeability, porosity, and effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

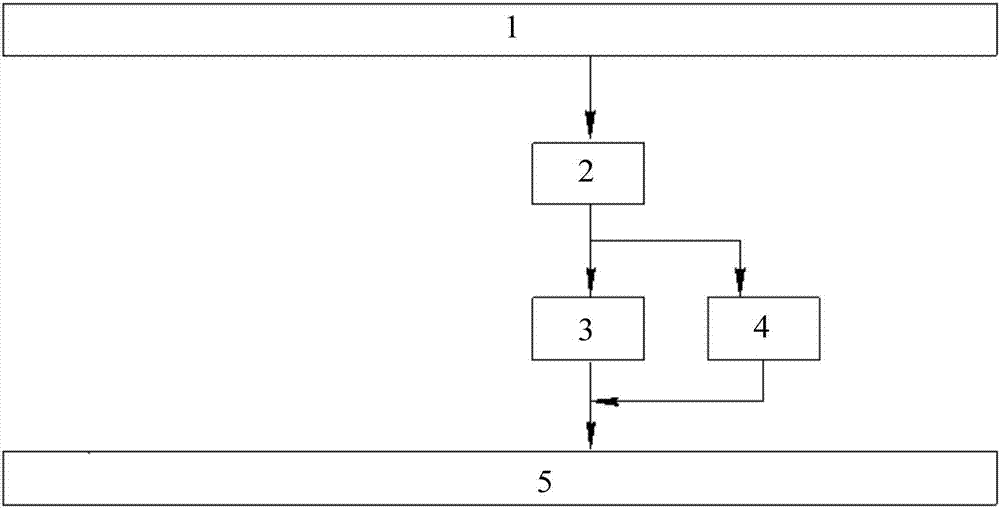

[0037] The embodiment provides a system (such as figure 1 shown).

[0038] The system includes a batching unit 1, a mixing unit 2, a granulation unit 3, a briquetting unit 4 and a sintering unit 5; wherein, the inlet of the mixing unit 2 is connected to the outlet of the batching unit 1, and the outlet of the mixing unit 2 is respectively connected to the granulation unit The inlet of 3 is connected with the inlet of briquetting unit 4; the outlet of granulation unit 3 and the outlet of briquetting unit 4 are respectively connected with the inlet of sintering unit 5;

[0039] A distributing device is provided at the exit of the mixing unit 2 which communicates with the granulating unit 3 and the briquetting unit 4 respectively; the distributing device can be a three-way distributor, a material distribution box or a plow unloader.

[0040] The batching unit 1 is equipped with a belt scale or a screw scale for weighing iron ore sintering raw materials;

[0041] The mixing unit...

Embodiment 2

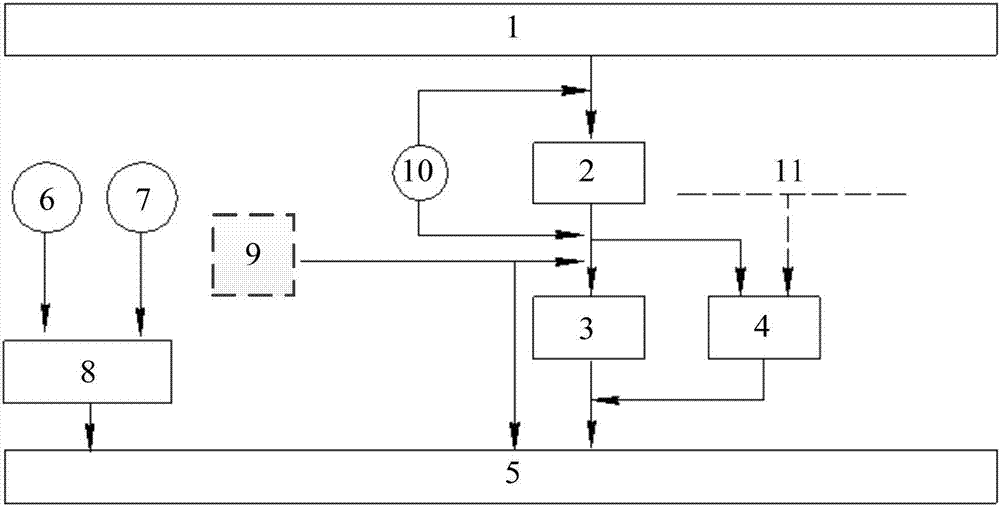

[0046] The embodiment provides a system (such as figure 2 shown), the system is further improved on the basis of the system provided in Example 1.

[0047] On the basis of the system provided in Embodiment 1, the system may also include a water injection unit 10, the water injection unit 10 is respectively connected to the inlet of the mixing unit 2 and the inlet of the granulation unit 3;

[0048] The system can also include an auxiliary agent adding unit 11; the outlet of the auxiliary agent adding unit 11 is connected with the inlet of the briquetting unit 4;

[0049] The system can also include a steam injection unit 9, the outlet of the steam injection unit 9 is connected to the granulation unit 3 and the sintering unit 5 respectively;

[0050]The sintering unit 5 may include a buffer bin, an ignition device 8, an air injection device 6, a gas injection device 7, and a distribution device; wherein, the outlet of the steam injection unit 9 is connected to the inlet of th...

Embodiment 3

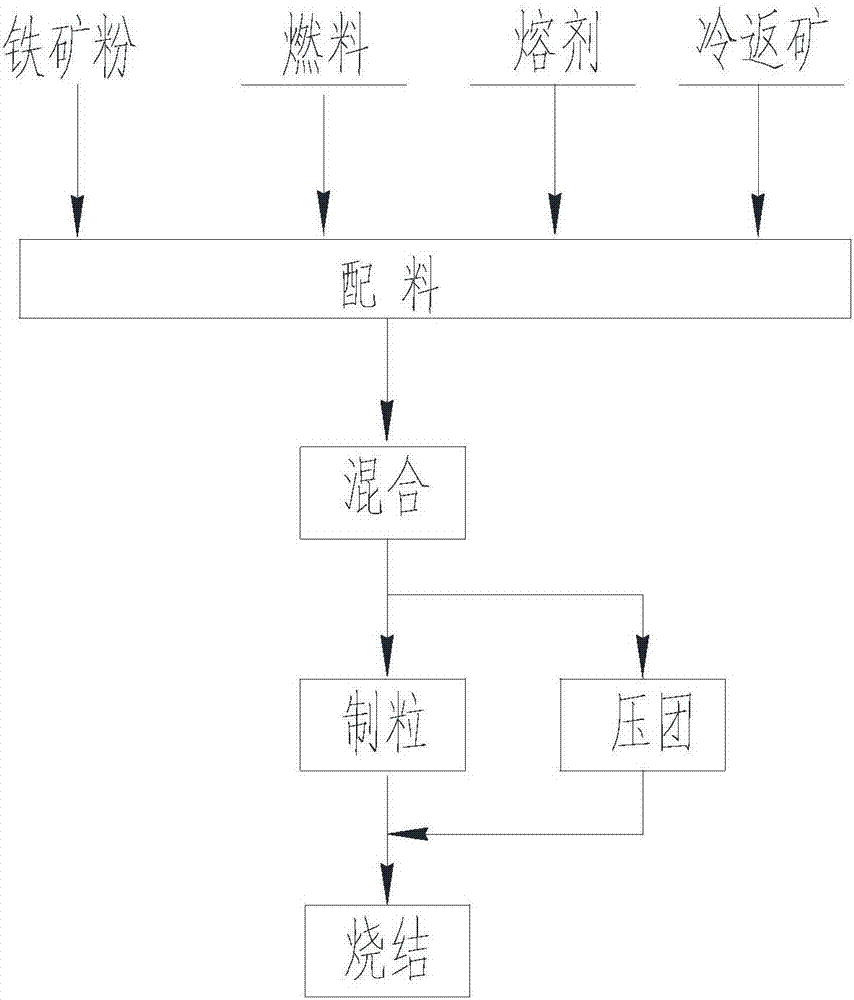

[0052] This embodiment provides a method for improving the air permeability of the iron ore sinter mixture (flow process is as follows image 3 shown), the method adopts the system provided in embodiment 2, and mainly includes the following steps:

[0053] Use batching unit 1 to weigh and prepare iron ore sintering raw materials, which include iron ore powder, flux, fuel and cold return ore; then transported to mixing unit 2 by belt conveyor for mixing. Water injection unit 10 adds water to the material;

[0054] After mixing, 50wt% of the material is separated into the briquetting unit 4 by the material distributing device and pressed into agglomerates with a diameter of 8 cm; the rest of the material enters the granulation unit 3 for granulation. add water to the material;

[0055] The briquetted material and the granulated material are transported together to the sintering unit 5 for sintering to obtain the finished product. During sintering, the sintering negative pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com