Flow guiding system for canyon area high dam hydropower engineering slag field valley water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings.

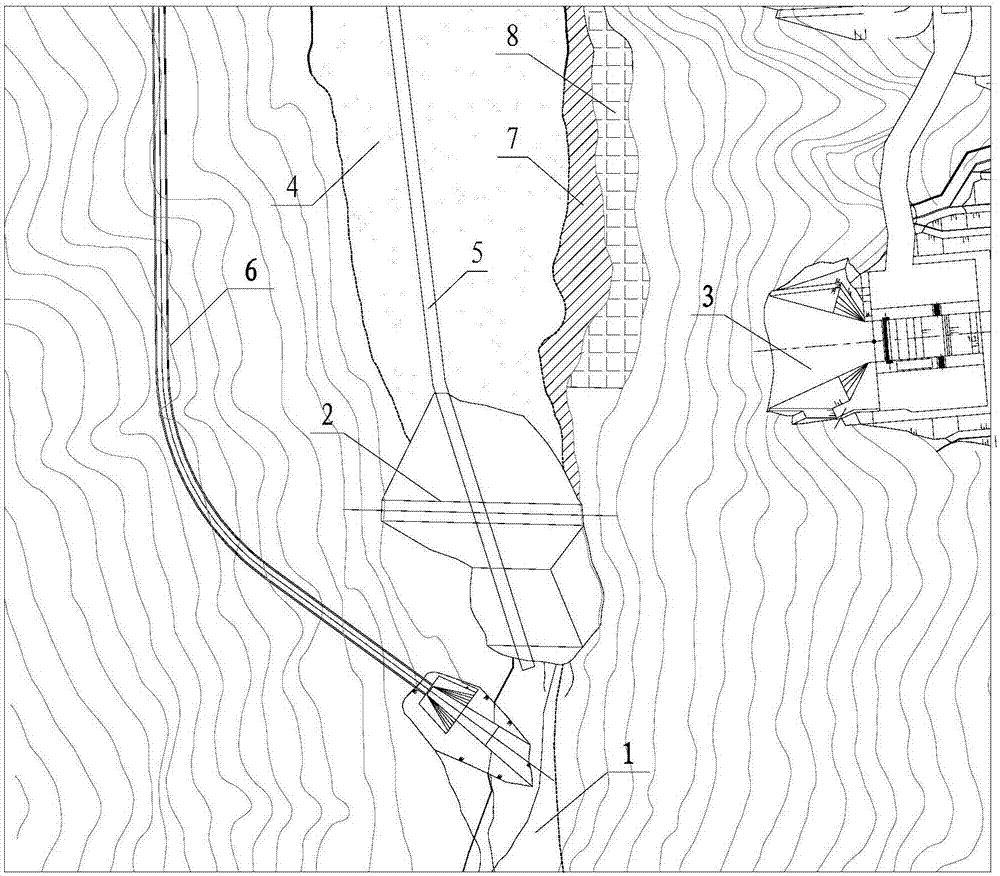

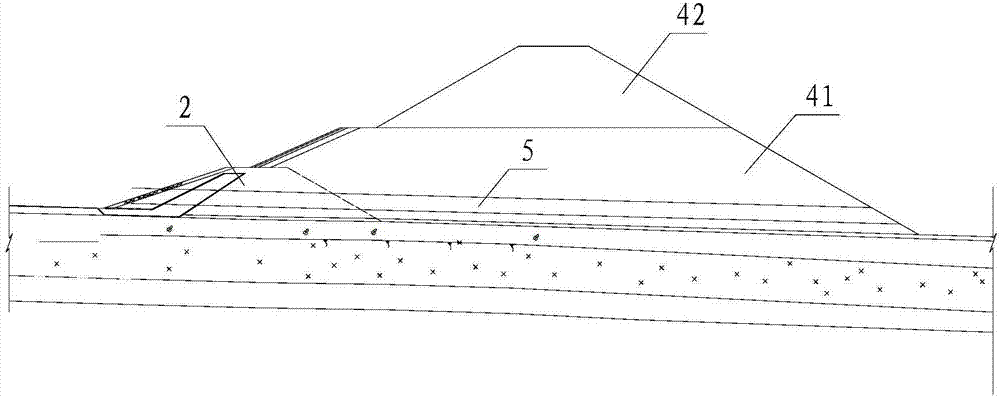

[0036] like figure 1 , figure 2 As shown, the present invention includes a retaining dam 2 arranged in the tributary valley 1, the retaining dam 2 is located upstream of the exit of the large-scale cavern group 3, and the rear of the retaining dam 2 is set as a slag dumping area 4, and the retaining dam 2 A drainage culvert 5 is arranged at the bottom of the dam, and a drainage hole 6 is arranged on the upstream side of the retaining dam 2. The body of the drainage hole 6 passes through the mountains and forests, and the outlet is located downstream of the slag dumping area 4 in the tributary valley 1 or other river slopes. Traditional ditch water treatment systems generally have only one drainage method, either through drainage holes or through drainage culverts, while the present invention comprehensively utilizes the two drainage methods, which can reduce engineerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com