A kind of flexible pd/sioc nano fiber mat and preparation method thereof

A nanofiber and flexible technology, applied in the field of flexible Pd/SiOC nanofiber felt and its preparation, can solve the problems that the mechanical strength and flexibility of the silica nanofiber felt cannot meet the requirements of high temperature filtration and nanocomposite materials, and can achieve a wide range of applications. The effect of citing prospects, good flexibility, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the flexible Pd / SiOC nanofiber mat provided by the present invention comprises the following steps: the spinning solution is sequentially subjected to electrospinning, pre-oxidation and pyrolysis to obtain a flexible Pd / SiOC nanofiber mat; the spinning solution is made of polystyrene , polycarbosilane, palladium acetylacetonate, xylene and dimethylformamide are mixed in a mass ratio of 3:8-20:0.2-2:30-50:50-70.

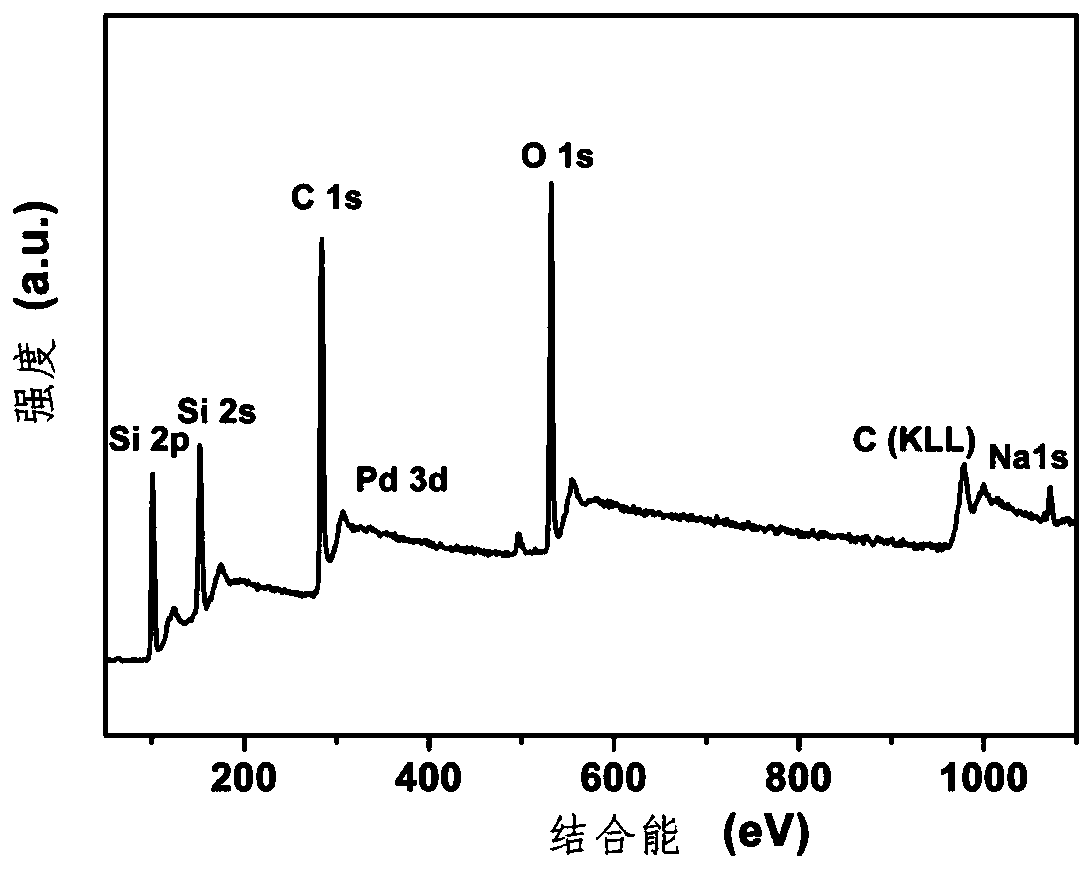

[0030] Configure the resulting spinning solution in this way to produce a Pd / SiOC nanofiber mat with higher flexibility. For its flexibility, see figure 1 , it can be seen from the figure that the fiber mat can be well wrapped on the glass surface without breaking. Mixing in this ratio is also beneficial to obtain fibers with uniform diameters after the subsequent electrospinning step. The SEM figure of gained fiber mat sees figure 2 , it can be seen that the fibers contained in the obtained fiber mat have a relatively uniform diame...

Embodiment 1

[0051] (1) Preparation of spinning solution: polystyrene (molecular weight 2,000,000), polycarbosilane (molecular weight 3500), palladium acetylacetonate, xylene and dimethylformamide are added in a mass ratio of 3:8:0.2:30:70 Mix in a reactor, then magnetically stir for 16 hours at a rotating speed of 800 rpm, and stir evenly to obtain a spinning solution;

[0052] (2) Electrospinning: use a metal needle with an inner diameter of 0.8 mm as the nozzle, the spinning voltage is 11 kV, the vertical distance from the needle tip to the receiving screen is 20 cm, the feeding rate is 12 μL / min, the spinning temperature is 20 °C, and the air The relative humidity is 30RH%. Using a drum to collect the filaments, the spinning solution obtained in step (1) is subjected to electrospinning, and the fibril felt is collected;

[0053] (3) Pre-oxidation: Put the fibril mat obtained in step (2) in a programmable temperature-controlled pre-oxidation furnace, and raise the temperature to 200°C ...

Embodiment 2

[0057] (1) Preparation of spinning solution: Add polystyrene (molecular weight 1,200,000), polycarbosilane (molecular weight 3000), palladium acetylacetonate, xylene and dimethylformamide in a ratio of 3:10:0.5:50:50 Mix in a reactor, then magnetically stir for 10 hours at a rotating speed of 600 rpm, and stir evenly to obtain a spinning solution;

[0058] (2) Electrospinning: a metal needle with an inner diameter of 1.5 mm was used as the nozzle, the spinning voltage was 16 kV, the vertical distance from the needle tip to the receiving screen was 25 cm, the feeding rate was 30 μL / min, the spinning temperature was 35 °C, and the air The relative humidity is 40RH%. Using a drum to collect the filaments, the spinning solution obtained in step (1) is subjected to electrospinning, and the fibril felt is collected;

[0059] (3) Pre-oxidation: put the fibril mat obtained in step (2) in a programmable temperature-controlled pre-oxidation furnace, and raise the temperature to 250° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com