Foundation pit supporting system and construction method thereof

A foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problem that large-angle inclined anchors are easy to exceed the construction red line, cannot be installed with large-angle inclined anchors, and the main structure in the foundation pit Inconvenient construction and other problems, to achieve the effect of improved horizontal shear resistance, high tensile strength, and overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

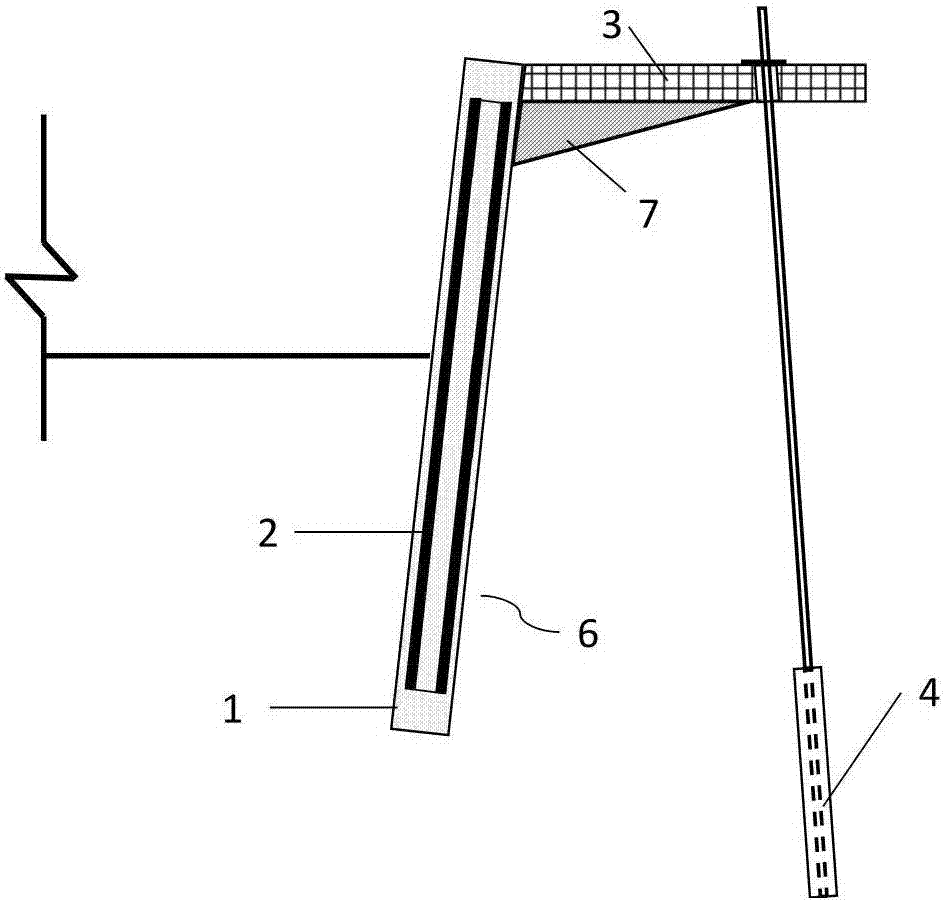

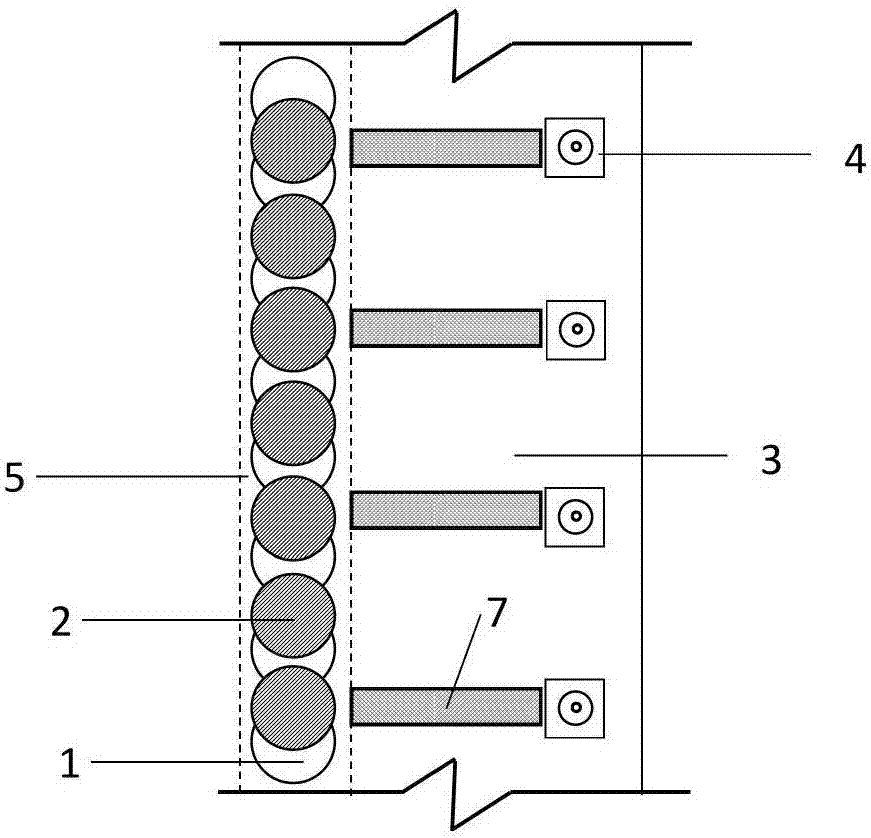

[0035] Such as figure 1 and figure 2 As shown, a foundation pit support system of the present invention includes a prestressed pipe pile cement-soil wall 6, a prestressed balance anchor 4, a ground cover plate 3 and a stiffener 7; the prestressed pipe pile cement-soil wall 6 includes Prestressed pipe pile 2 and triaxial cement-soil mixing pile 1, the prestressed pipe pile 2 is inserted in the triaxial cement-soil mixing pile 1; the cement-soil wall 6 of the prestressed pipe pile and the ground cover plate 3 are consolidated connection; the stiffener 7 is set at the junction corner of the prestressed pipe pile cement-soil wall 6 and the ground cover 3; the end of the prestressed balance anchor rod 4 is anchored in the hard soil layer, and the other end of the Fixed on the ground cover plate 3.

[0036] The prestressed pipe pile cement-soil wall 6 described in this embodiment is a tilting type, and its tilting angle≯15°, that is, its tilting angle is not more than 15 degrees,...

Embodiment 2

[0042] The construction method of the foundation pit support system of the present invention, before the construction, firstly ensure the three connections and one leveling of the site, that is, the water connection, the electricity connection, the road connection and the leveling of the site, so as to ensure the safety of electricity and water use. The construction process of the foundation pit support system is as follows: dewatering at the well point, measurement and setting out, excavation of the guide groove 5, construction of the three-axis cement-soil mixing pile machine in place, insertion of prestressed pipe piles 2, pouring of the ground cover 3, The specific steps of determining the hole position of the prestressed balance anchor rod 4, forming the hole, clearing the hole, and grouting are as follows:

[0043]a. Dewatering at the well point: Dewater the well point of the foundation pit about two weeks before the excavation of the earthwork, and excavate the earthwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com