H-shaped steel column framework system of fabricated modularized self-resetting steel structure for multi-storey and high-rise building

A frame system and H-shaped steel technology, applied in the direction of building components, building types, building structures, etc., can solve the problems that affect the safety performance of buildings, the quality of welds is not suitable for control, and the construction speed is slow, so as to achieve flexible connection methods and reduce Effect of construction period and reduction of steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

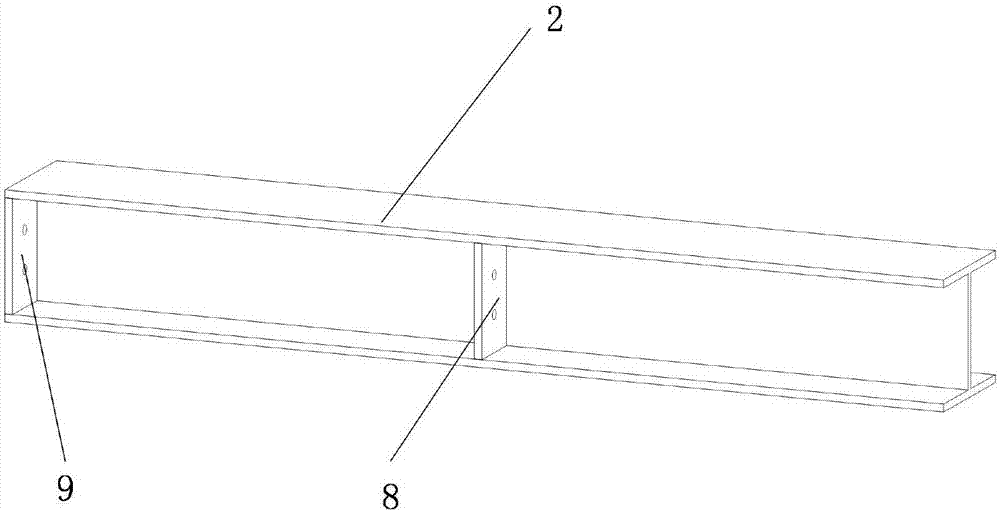

[0023] Such as image 3 As shown, the beam (2) in the multi-high-rise assembled modular self-resetting steel structure H-shaped steel column frame system adopts H-shaped steel, and the end plate I (9) is welded at the beam end near the column, and vertically welded in the middle of the beam Reinforced ribs (8).

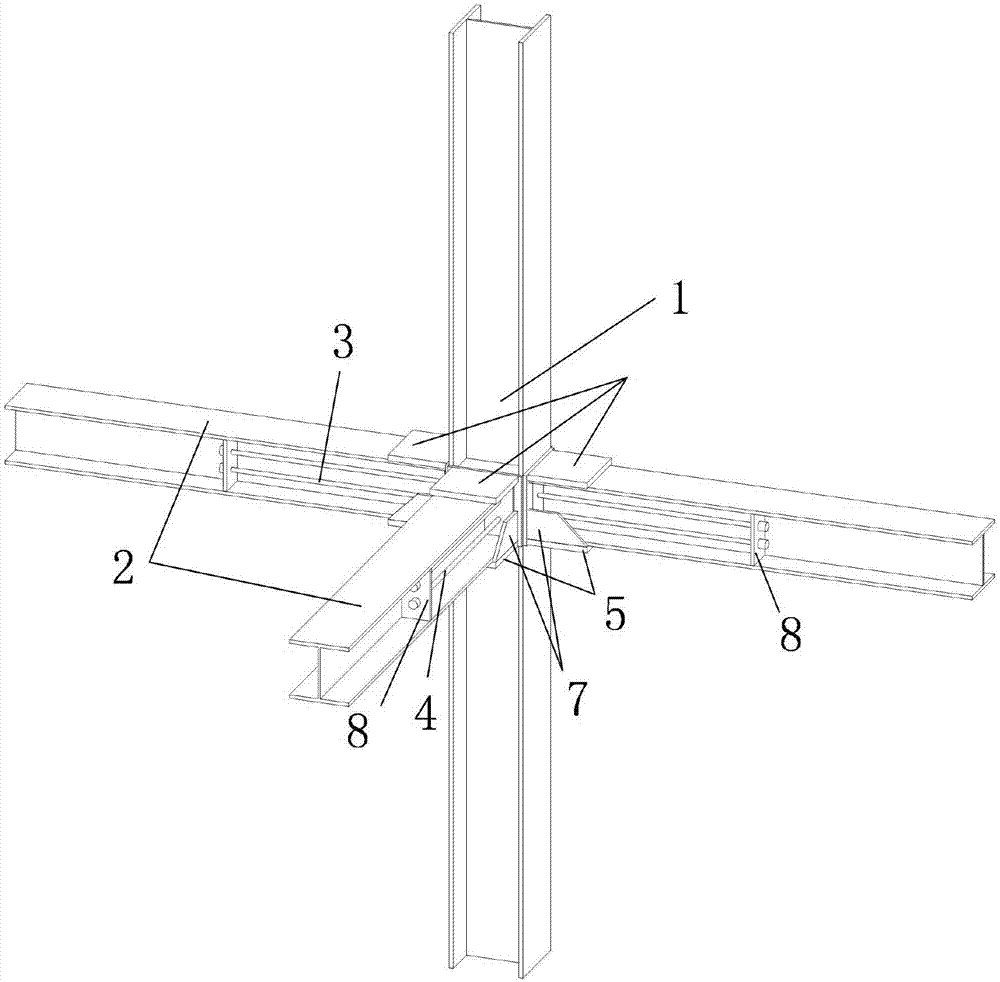

[0024] Such as Figure 4 As shown, the length of the H-shaped steel column (1) in the multi-high-rise assembled modular self-resetting steel structure H-shaped steel column frame system is the floor height, and the supporting plate (5) is welded on three adjacent sides of the middle part of the H-shaped steel column (1). , and ensure that the supporting plate (5) is horizontal, weld the cover plate (6) horizontally at a distance of one beam height above the supporting plate (5), and ensure that the distance between the upper surface of the supporting plate (5) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com