Oil guiding mechanism to avoid oil waste

A technology of oil and oil guide tubes, applied in the field of oil guide tubes, can solve problems such as energy waste, environmental pollution, and waste, and achieve the effects of avoiding oil waste, environmental pollution, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

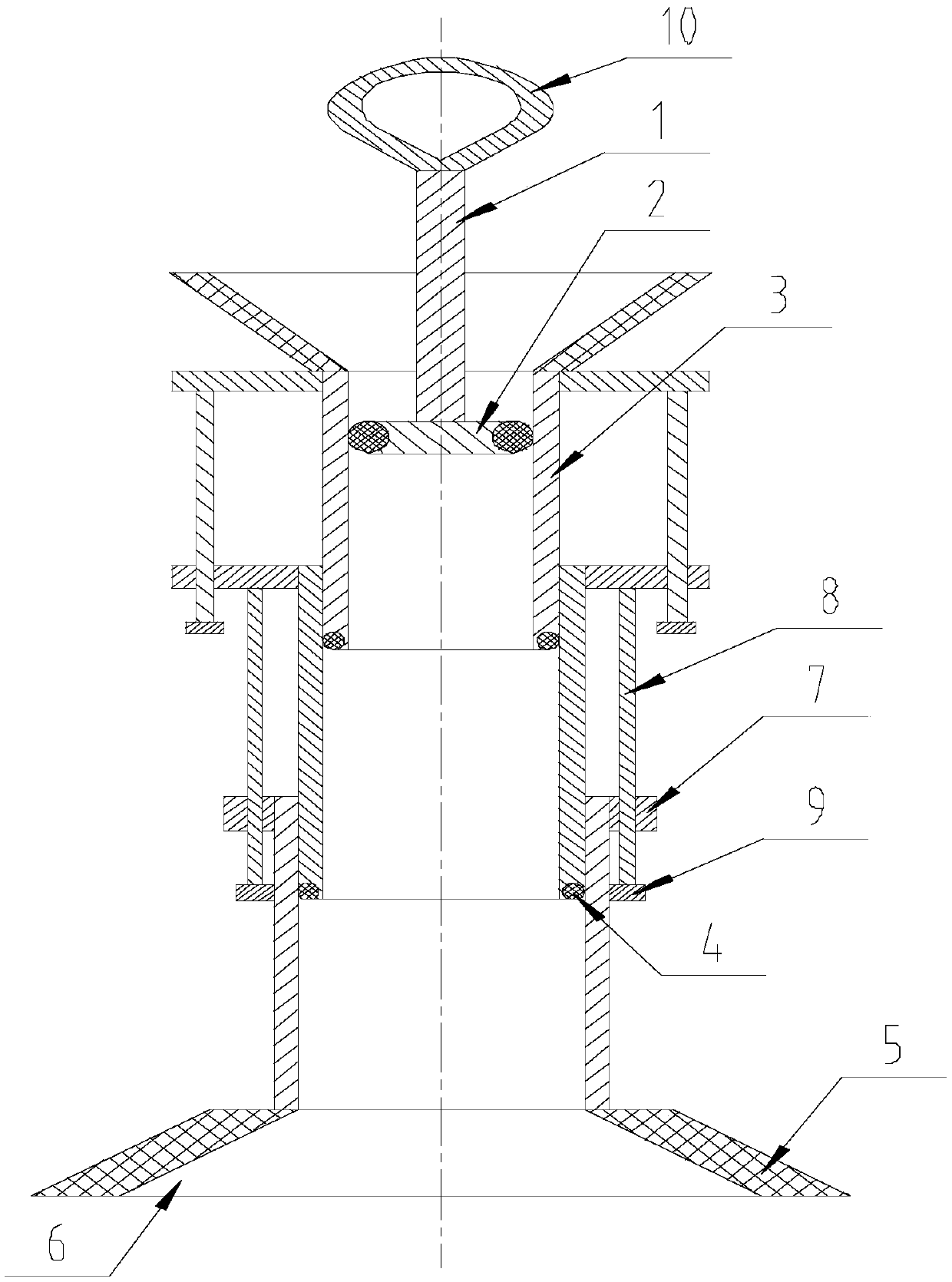

[0028] Such as figure 1 As shown, the oil guide mechanism for avoiding oil waste in the present invention includes a conduit member and a piston rod 1, and the conduit member includes several oil guide cylinders 3 connected in series, both ends of the oil guide cylinder 3 are open, and the guide tubes The outer diameters of the oil cylinders 3 are different, and the inner diameters of the oil guide cylinders 3 are different. Between the oil cylinders 3: one end of the oil guide cylinder 3 with a smaller outer diameter is located in the center hole of another oil guide cylinder 3 with a larger outer diameter, and the outer diameter of the oil guide cylinder 3 with a smaller outer diameter It is consistent with the inner diameter of the oil guide cylinder 3 with a larger outer diameter, and the outer wall of the previous oil guide cylinder 3 is in seamless contact with the center hole wall of the next oil guide cylinder 3;

[0029] A piston 2 is arranged at one end of the pisto...

Embodiment 2

[0032] The present invention is based on embodiment 1, and the present invention is further described.

[0033] Such as figure 1 As shown, in the oil guiding mechanism for avoiding oil waste in the present invention, a sealing ring 4 is provided on the side wall of the oil guiding cylinder 3 at one end of the center hole of another oil guiding cylinder 3, and the sealing ring 4 is an O-ring. The setting of the sealing ring 4 increases the sealing performance between the adjacent oil guiding cylinders 3 .

[0034] Further, suction cups 5 are provided at both ends of the conduit member, and flow guide holes 6 are provided on the suction cups 5 , and the flow guide holes 6 are coaxial with the oil guide cylinder 3 . The suction cup 5 increases the tightness of the joint between the conduit member and the oil barrel or the device for collecting oil.

[0035]Further, the diversion hole 6 is a tapered hole, its small diameter end is close to the oil guide cylinder 3, and its large...

Embodiment 3

[0037] The present invention is based on embodiment 1, and the present invention is further described.

[0038] Such as figure 1 As shown, the oil guide mechanism for avoiding oil waste in the present invention is equipped with a stop ring 7 at one end of the oil guide tube 3, and the axis of the stop ring 7 is collinear with the axis of the oil guide tube 3;

[0039] A limit hole is set on the limit ring 7, the limit hole is a through hole, and its axis is parallel to the axis of the oil guide cylinder 3;

[0040] Among the adjacent oil guide cylinders 3, a limit rod 8 is arranged on the limit ring 7 on the oil guide cylinder 3 with a smaller outer diameter near the other end of the oil guide cylinder 3 with a larger outer diameter. The axis of the limit rod 8 is parallel to the axis of the oil guide cylinder 3;

[0041] In the adjacent oil guide cylinder 3, the limit rod 8 on the limit ring 7 on the oil guide cylinder 3 with a smaller outer diameter and the limit ring 7 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com