High-voltage LED light belt

A technology of LED light strip and high voltage, applied in the field of lighting, can solve the problem that the plug of the light strip is easy to generate sparks and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

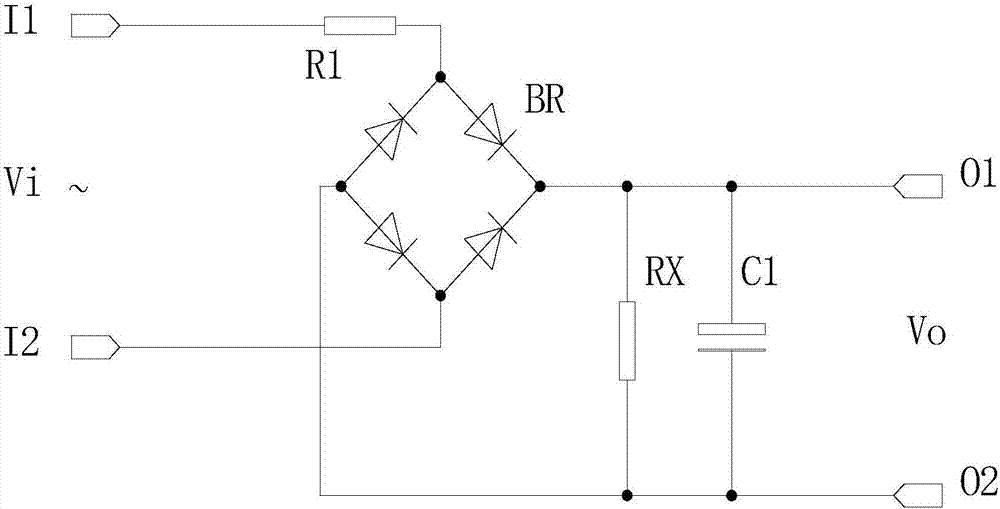

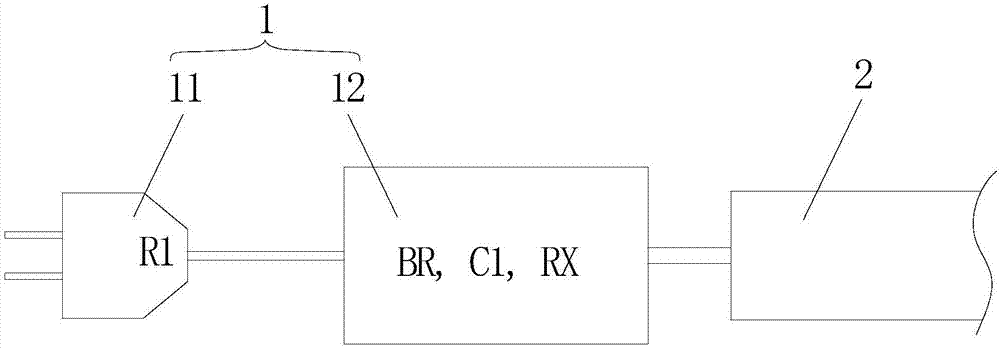

[0022] Such as figure 1 with figure 2 As shown, the high-voltage LED light strip provided in this embodiment includes an electrical connector 1 and a light strip 2, the light strip 2 is provided with an LED circuit, the electrical connector 1 is provided with a rectification and filtering circuit, and the rectification The filter circuit includes a rectifier bridge BR and a filter capacitor C1, the input terminals I1 and I2 of the rectifier bridge BR are connected to the mains Vi, the output terminal of the rectifier bridge BR is connected to the filter capacitor C1, and the two ends of the filter capacitor C1 form the output of the rectifier filter circuit The terminals O1 and O2 are connected to the LED circuit, and the feature is that the rectification filter circuit also includes an NTC thermistor R1, and one input terminal of the rectifier bridge BR is connected to the mains Vi through the NTC thermistor R1.

[0023] In the high-voltage LED strip provided in this embodi...

Embodiment 2

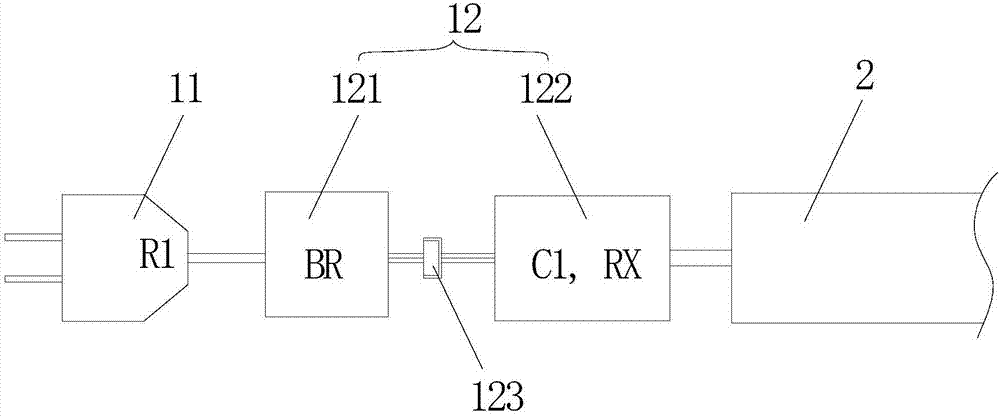

[0031] Such as Figure 4 As shown, this embodiment is similar to the high-voltage LED light strip described in Embodiment 1, the difference lies in:

[0032] The electrical connector 1 includes a plug 11, a power supply box 121 and a filter box 122, the NTC thermistor R1 and the rectifier bridge BR are installed in the power supply box 121, and the filter capacitor C1 and the bleeder resistor RX are installed in the filter box Within 122.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com