High-specific-radioactivity radioactive wastewater negative pressure evaporation concentration treatment system and method thereof

A technology of negative pressure evaporation concentration and radioactive wastewater, which is applied in radioactive purification, nuclear engineering, etc., can solve the problems that it cannot be used to treat tritium-containing wastewater, does not meet the principle of waste minimization, and is not suitable for treating high-level radioactive wastewater. Prospect of commercial application, reduction of external radiation exposure risk, significant effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Attached below Figure 1 to Figure 6 The present invention will be further described with reference to specific examples, and the embodiments of the present invention include but are not limited to the following examples.

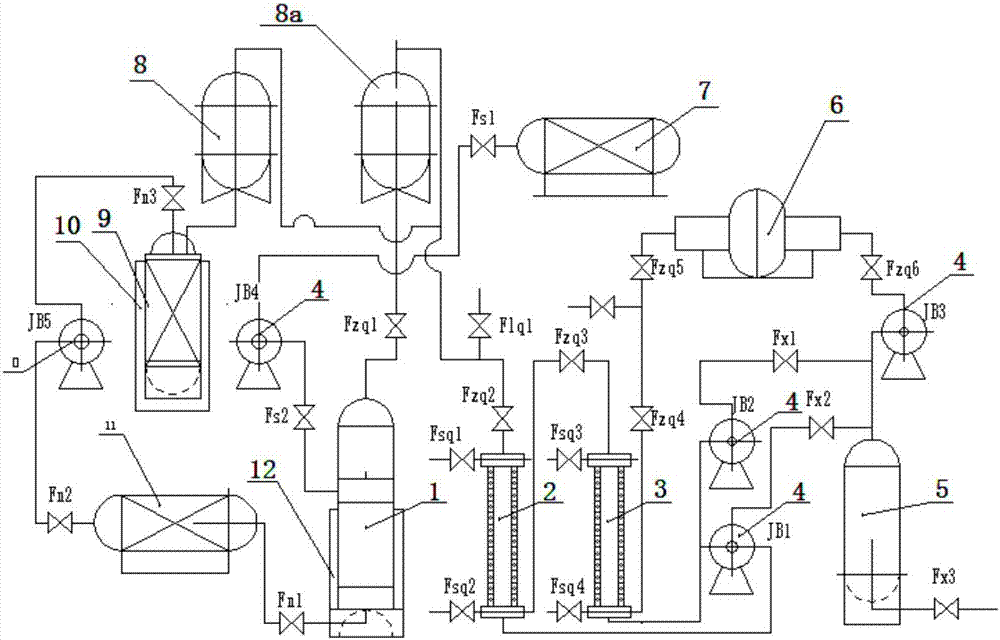

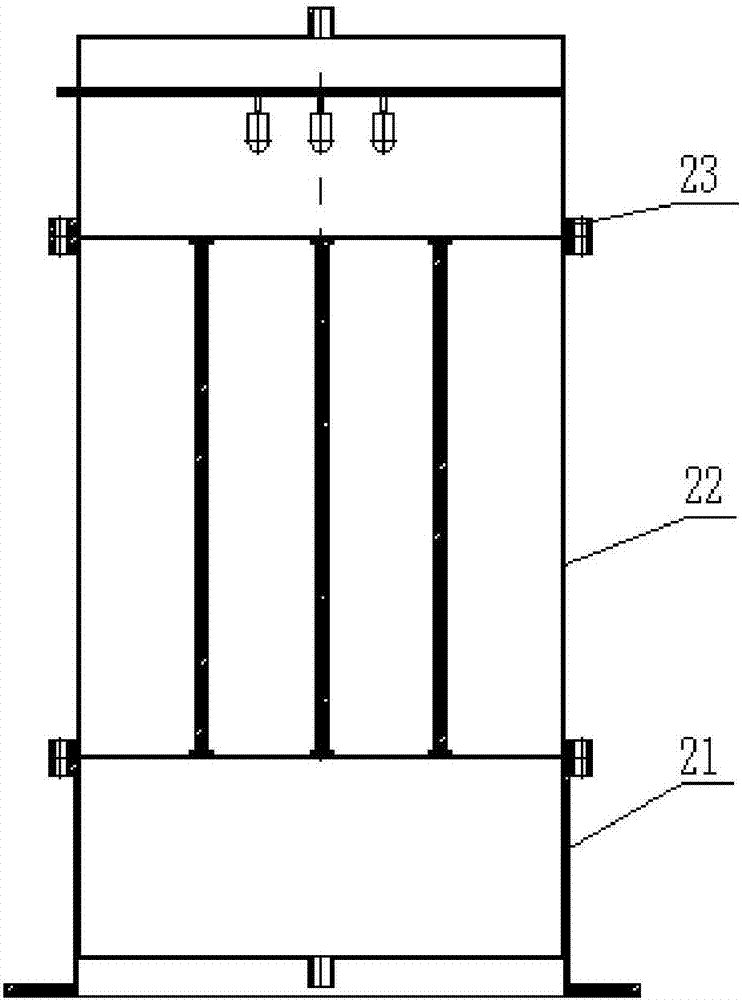

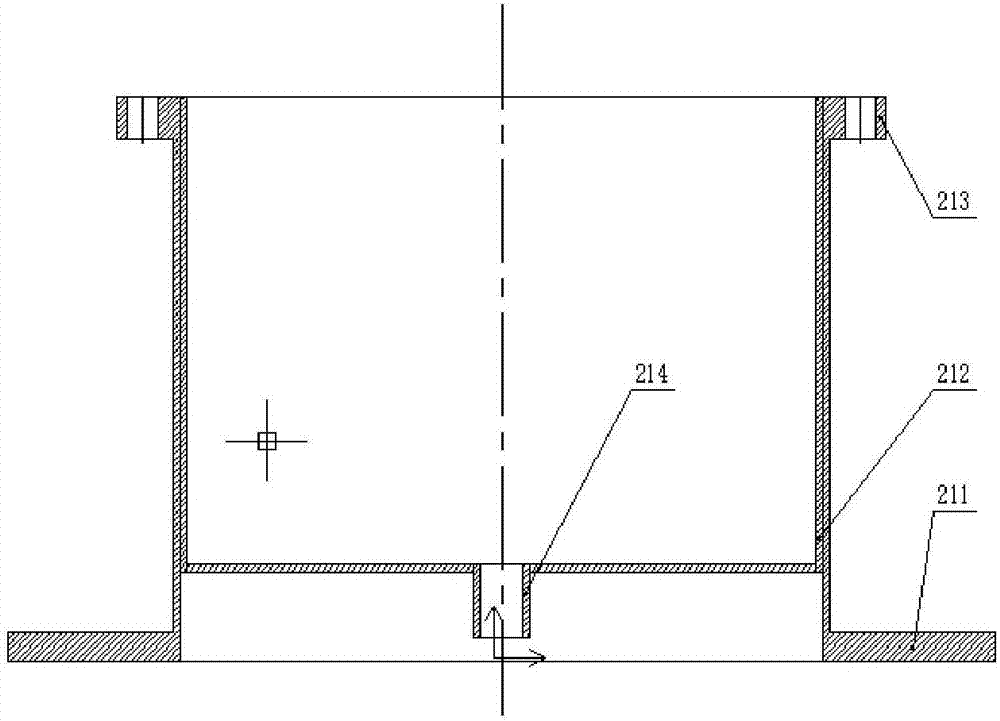

[0037] figure 1 It is a schematic diagram of a negative pressure evaporation concentration treatment system for high specific radioactivity wastewater of the present invention. Such as figure 1 As shown, a negative pressure evaporation and concentration treatment system for highly specific radioactive waste water of the present invention mainly includes a well-type heating electric furnace 10 and a well-type heating electric furnace 12, a negative pressure evaporator 1, a primary condenser 2, and a secondary condenser 3 , metering pump 4, condensed water temporary storage tank 5, (water ring type) vacuum pump 6, waste water raw water tank 7, first demister tower 8a, second demister tower 8, negative pressure dryer 9, concentrated waste water tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com