Fuel battery low-temperature starting grading preheating control method

A fuel cell system and fuel supply system technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problem of slow start-up speed, high energy consumption for fuel cell stack preheating, and no consideration of ambient temperature differences, etc. problem, to achieve the effect of prolonging durability and starting efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

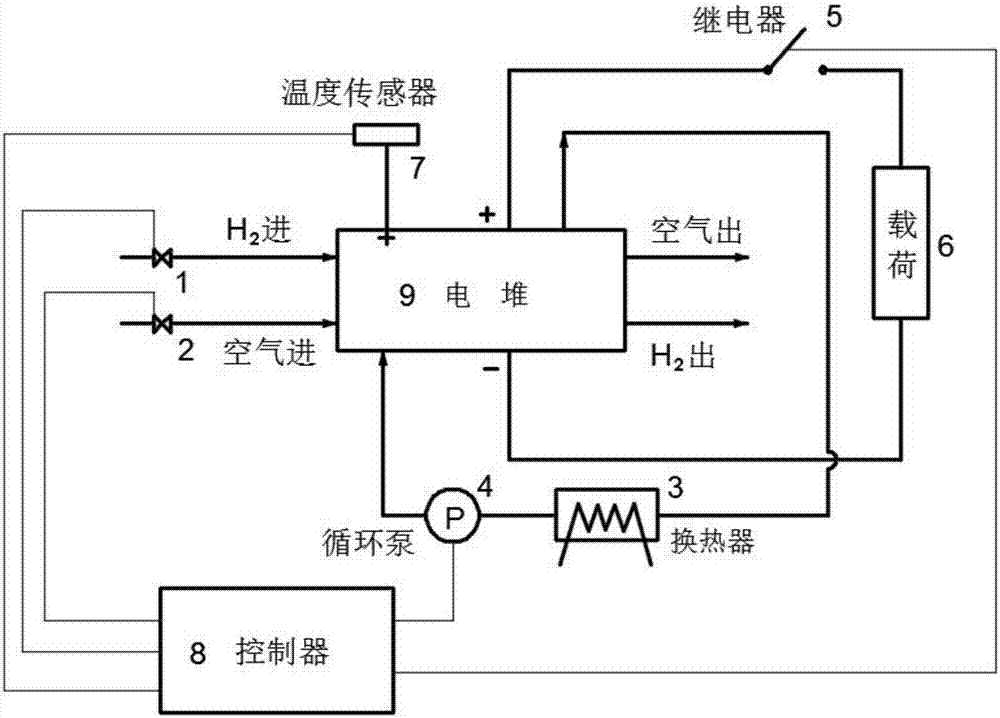

[0026] The fuel cell system includes a stack, a sensor for measuring stack temperature, a fuel supply system, an oxidant supply system, a cooling medium circulation system, a stack power output circuit, an external heat source heating system, an internal heat source heating system, and a general control system. like figure 1 As shown, when starting starts, the temperature sensor 7 monitors the battery temperature T, and the controller 8 judges whether to heat with an external heat source or an internal heat source. When the external heat source is used for heating, the controller 8 controls the circulating pump 4 to start to work, the cooling medium passes through the heat exchanger 3 for heat exchange and temperature rise, and then enters the electric stack 9 to heat the electric stack with an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com