Combination converter capable of realizing output tight adjustment

A converter and tight adjustment technology, applied in output power conversion devices, regulating electrical variables, instruments, etc., can solve problems such as reducing power density and increasing cost, reducing the number of magnetic cores, improving efficiency and power density, Topologically simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

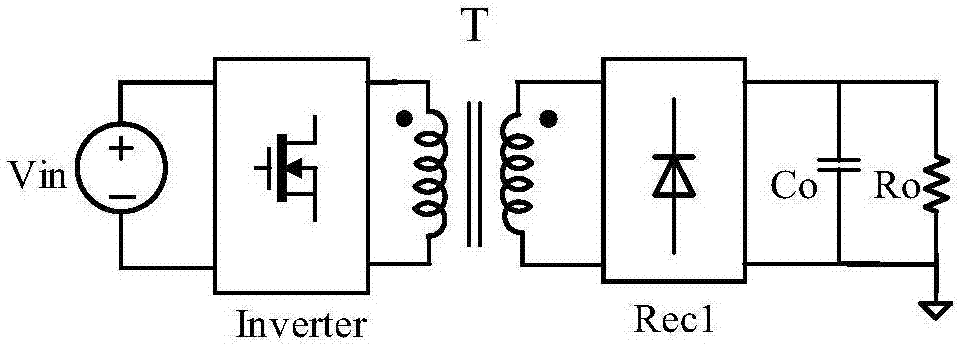

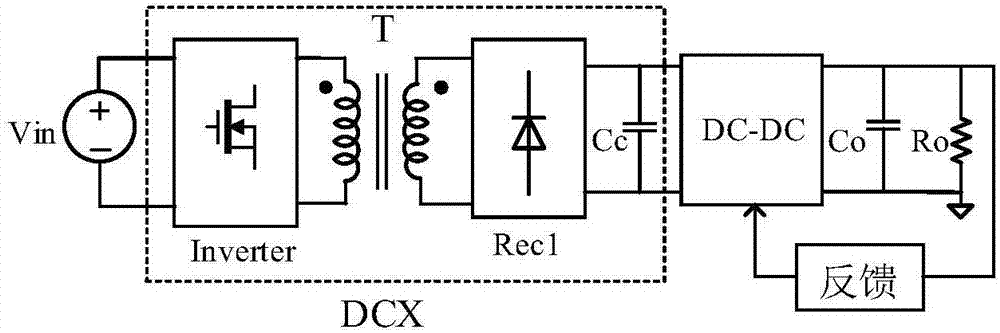

Problems solved by technology

Method used

Image

Examples

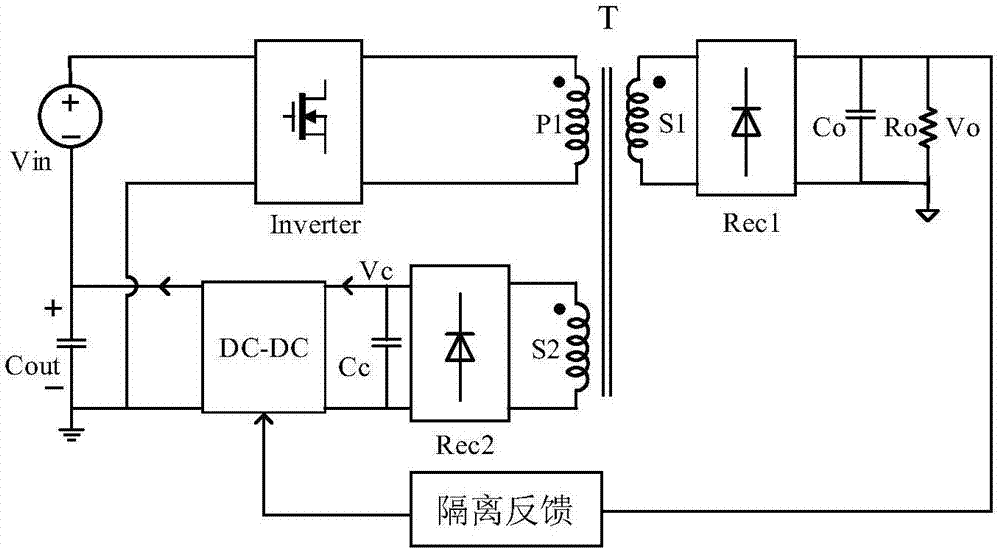

Embodiment 1

[0042] The combined converter with tightly regulated output includes an input DC voltage Vin, a transformer T, a high-frequency inverter circuit Inverter located on the primary side of the transformer, an output winding S1 located on the secondary side of the transformer, and a first rectifier circuit Rec1. The circuit Rec1 is connected to the output capacitor Co; the primary side winding of the transformer T is composed of the first winding P1 and the auxiliary winding S2, wherein the first winding P1 is connected to the output of the high-frequency inverter circuit Inverter, and the auxiliary winding S2 is rectified by the second The circuit Rec2 is connected to the non-isolated DC-DC conversion circuit; the output capacitor Cout of the non-isolated DC-DC conversion circuit is connected in series with the input DC voltage Vin, and the output of the input DC voltage Vin is used as the DC input of the high-frequency inverter circuit Inverter; The DC output voltage Vo is sampled...

Embodiment 2

[0045] In order to keep the input voltage of the high-frequency inverter circuit Inverter stable, an input capacitor Cin is connected in parallel on its input side, such as Figure 4 shown. The structure of the rest of the circuit is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0047] In order to meet the requirement that no back pressure is generated at both ends of the non-isolated DC-DC output capacitor Cout at the start-up moment, a diode D is connected in antiparallel to both ends of the output capacitor. After the circuit starts, the diode D bears the back pressure without affecting the normal operation of the circuit, such as Figure 5 shown. The structure of the rest of the circuit is the same as that in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com