Supported organic Cu(I) catalyst and preparation method and application thereof

A supported, catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalysts, catalysts, catalytic reactions, etc., can solve the problems of polluting the environment, unable to reuse, and difficult to purify products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of supported organic Cu (I) catalyst, comprises the following steps:

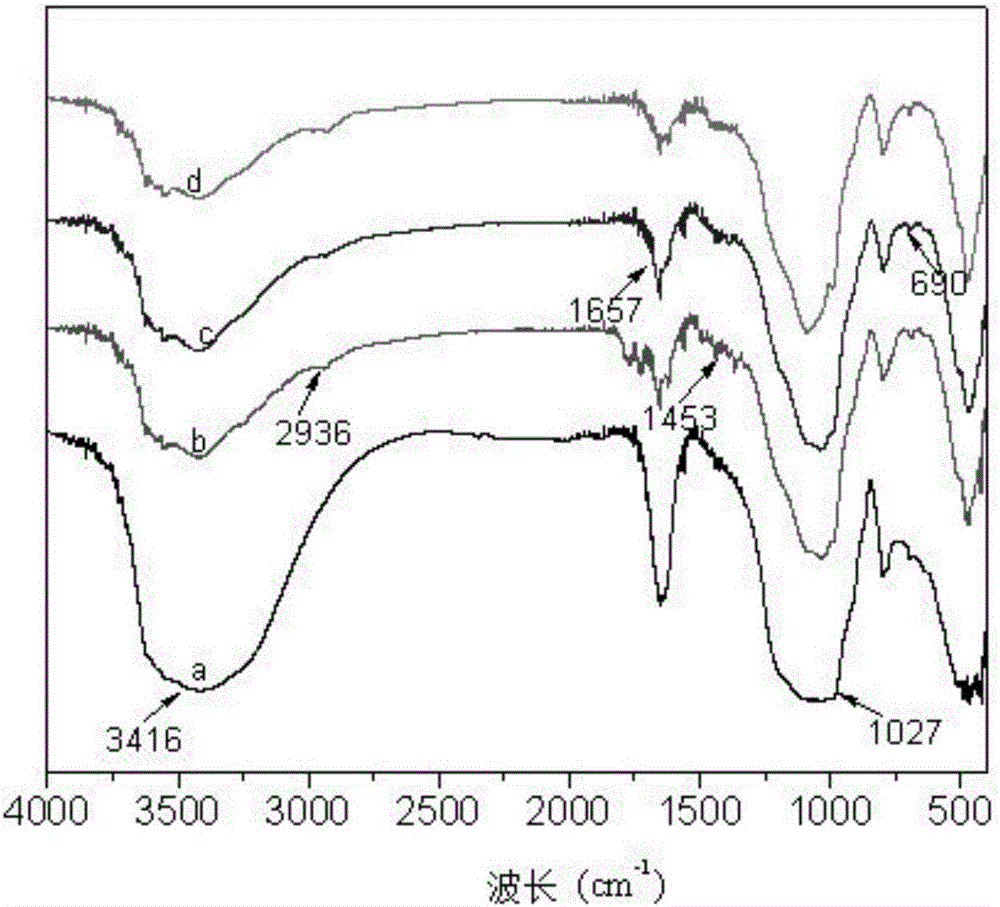

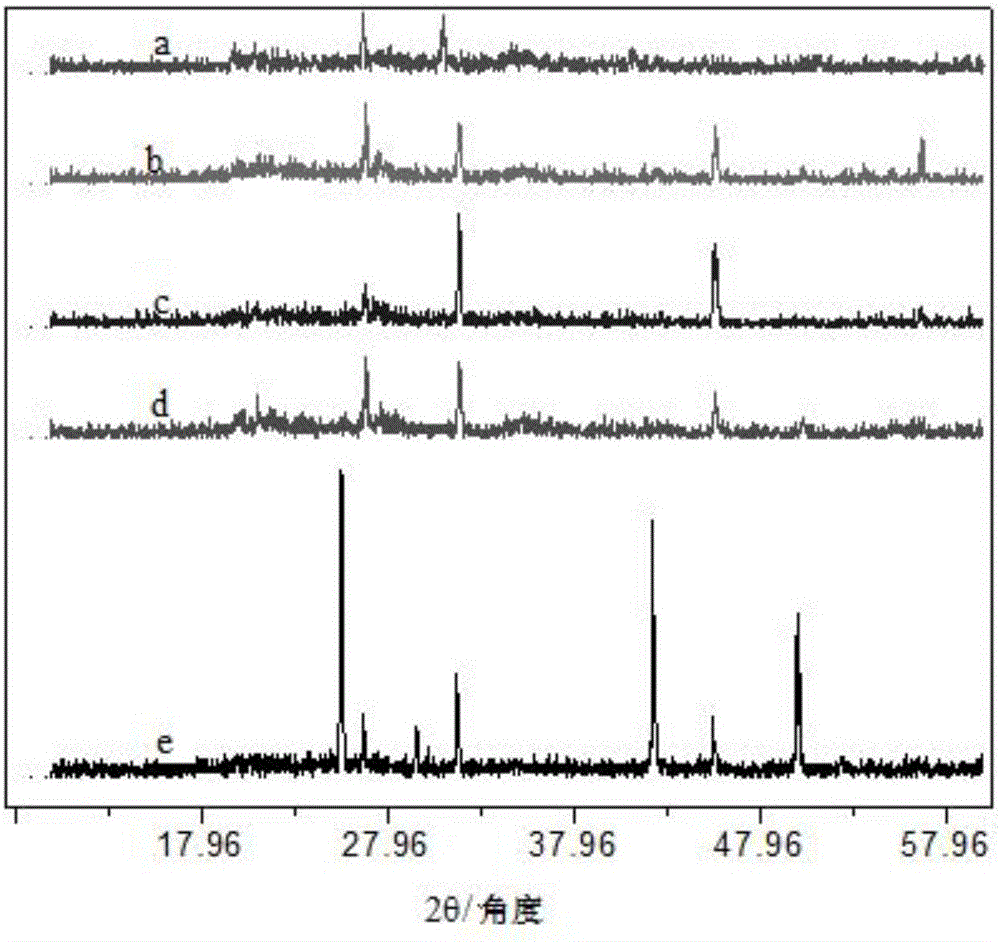

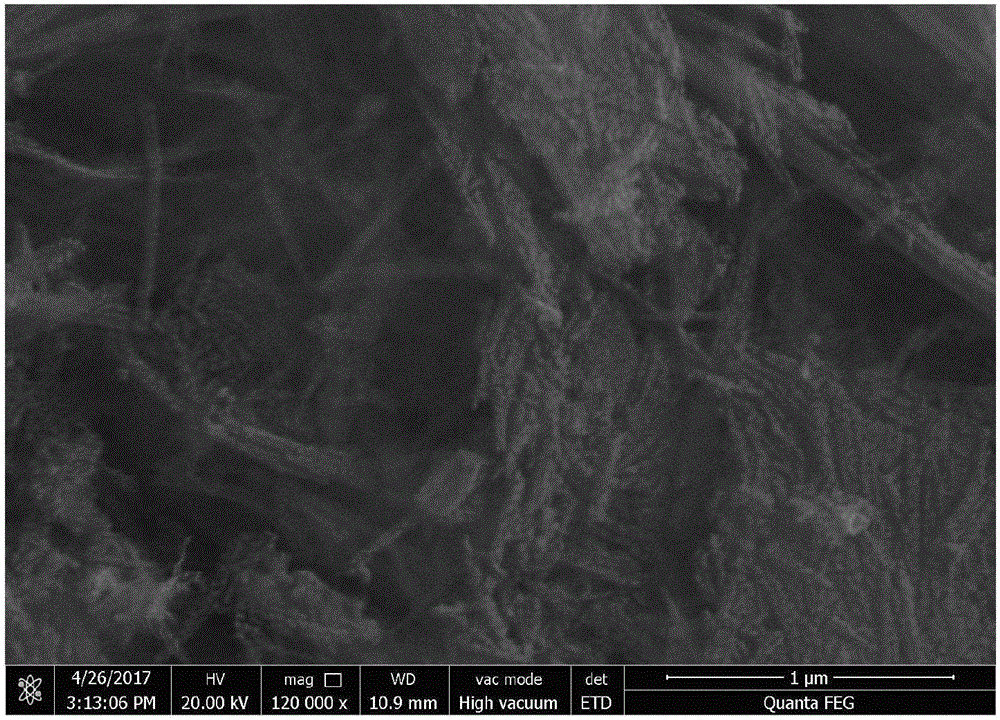

[0032] Carrying out the first grafting reaction of acidified attapulgite and mercaptosilane coupling agent in a benzene solvent to obtain mercapto-modified attapulgite;

[0033] Carrying out the second grafting reaction of the mercapto-modified attapulgite and isatoic anhydride in an alcohol solvent to obtain isatoic anhydride-mercapto-modified attapulgite;

[0034] The isatic anhydride-mercapto-modified attapulgite and cuprous halide are subjected to complexation and coordination reaction in an alcohol solvent to obtain a supported organic Cu(I) catalyst.

[0035] In the invention, acidified attapulgite (HATP) and mercaptosilane coupling agent are subjected to a first grafting reaction in a benzene solvent to obtain mercapto-modified attapulgite (SH-HATP). In the present invention, the pH value of the acidified attapulgite is preferably 2 to 4, mo...

Embodiment 1

[0074] Weigh 12g of attapulgite (ATP) into a 100mL three-necked flask, add 60mL of 4mol / L hydrochloric acid solution, disperse under ultrasonic waves for 20min, stir and reflux at 70°C for 24h, suction filter after the reaction, and add a small amount of deionized Dissolve in water, adjust the pH to about 3 with 2mol / L NaOH solution, and vacuum dry at 100°C to obtain a light yellow solid, which is acidified attapulgite (HATP);

[0075] Weigh 10g of acidified attapulgite into a 50mL flask, add 25mL of xylene, slowly add 2mL of γ-mercaptopropyltrimethoxysilane dropwise under stirring, disperse under ultrasonic waves for 20min, stir and reflux at 60°C for 4h, and filter the product with suction After separation, wash with xylene, absolute ethanol and deionized water in sequence, and vacuum dry at 100°C to obtain mercapto-modified attapulgite (SH-HATP);

[0076] Weigh 10g SH-HATP in a 50mL flask, add it to 25mL ethanol, disperse under ultrasonic wave for 20min, then add 2.5g isatoic...

Embodiment 2

[0083] The acidified attapulgite (HATP) that is 3.5 is prepared according to the method for embodiment 1 pH;

[0084] Weigh 10g of acidified attapulgite into a 50mL flask, add 30mL of benzene, slowly add 2mL of γ-mercaptopropyltriethoxysilane dropwise under stirring, disperse under ultrasonic waves for 25min, stir and reflux at 65°C for 3.5h, the product is pumped After filtration and separation, it was washed with benzene, absolute ethanol and deionized water in sequence, and vacuum-dried at 100°C to obtain mercapto-modified attapulgite (SH-HATP);

[0085] Weigh 10g of SH-HATP in a 50mL flask, add it to 30mL of methanol, disperse under ultrasonic waves for 20min, then add 2.5g of isatoic anhydride, stir and reflux at 75°C for 9h, the product is separated by suction filtration, washed with ethanol, and dried at room temperature , to obtain isatoic anhydride-mercapto modified attapulgite (ATBA-SH-HATP);

[0086] Weigh 3g of ATBA-SH-HATP into a 50mL flask, add 15mL of ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com