Method and system for spraying codes through adoption of robot

A robot and coding technology, applied in printing, printing devices, etc., can solve problems such as peeling off and easy paper barcodes, and achieve the effect of ensuring consistency and excellent anti-staining ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

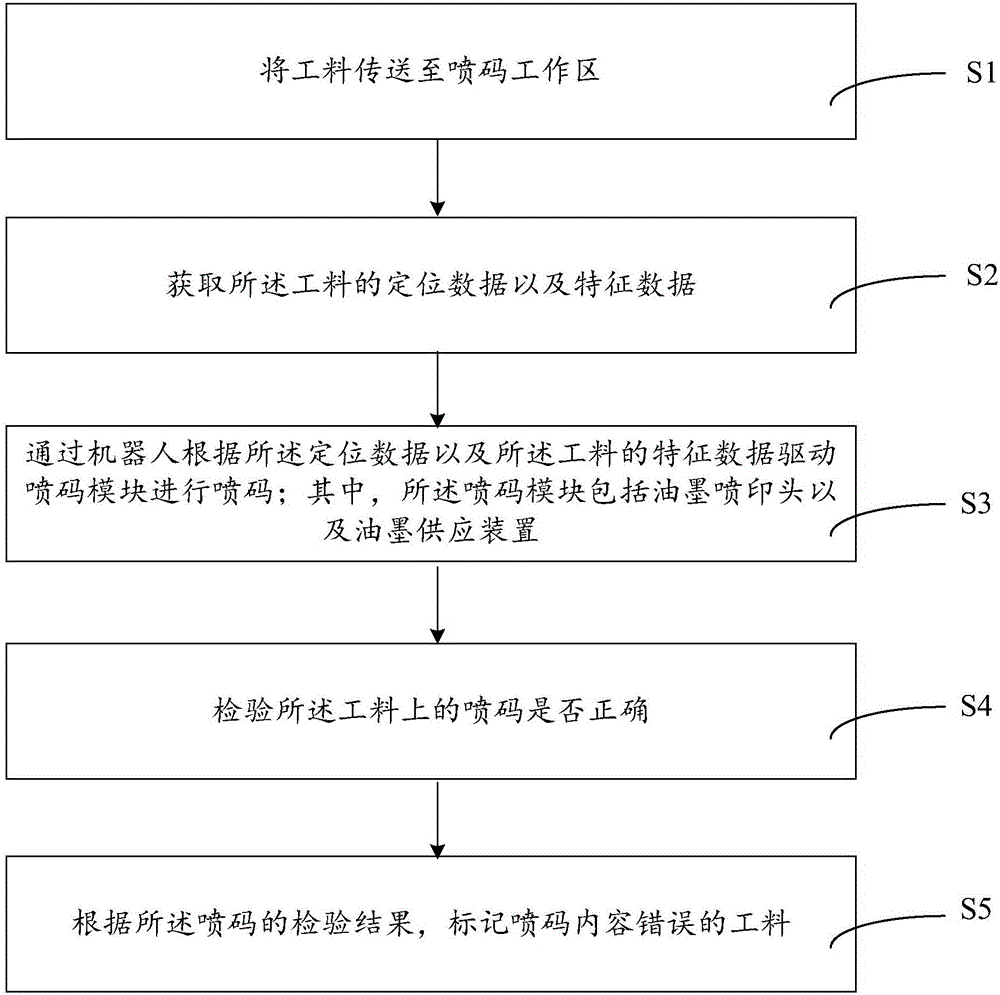

[0041] Such as figure 1 Shown is a method of using robot inkjet coding, including steps:

[0042] S1, transfer the materials to the coding work area.

[0043] In this step, the transfer of the materials to the inkjet working area can be carried out through slide rails, which can be driven by synchronous transmission mechanisms and stepping motors, and the width of the slide rails can be adjusted according to the size of the materials. The width adjustment mechanism adjusts the width between the two slide rails (the width adjustment mechanism can be a manual fine adjustment mechanism set on the connecting rod of the two slide rails, or an electric roller screw mechanism can be used to drive one of the slide rails. track for lateral movement). Certainly, as an alternative embodiment, a conveyer belt may be used for conveying, or a manipulator may be used for conveying. Generally speaking, the way of transmission through slide rails has high efficiency and good precision. Alth...

Embodiment 2

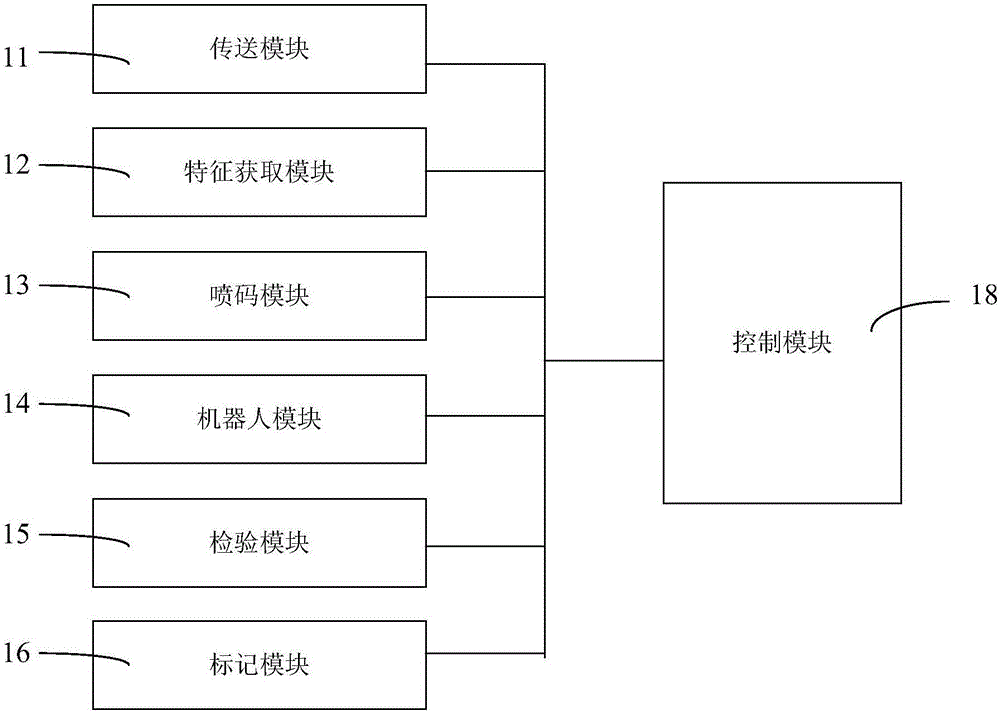

[0057] Based on the method provided in Embodiment 1, such as figure 2 As shown, the present embodiment provides a system using robot coding, the system includes: a transmission module module 11, which is used to transfer the materials to the coding work area; a feature acquisition module 12, which is used to obtain the positioning data of the materials And characteristic data; Inkjet code module 13, described inkjet code module comprises ink jet printing head and ink supply device, is used for carrying out inkjet code on work material; Robot module 14, is used for according to the characteristic of described positioning data and described work material Data-driven inkjet module.

[0058] In this embodiment, the feature acquisition module 12 includes: an image acquisition unit, configured to acquire image data of the work material, and acquire the positioning data and feature data according to the image data.

[0059] In this embodiment, the system further includes: a verific...

Embodiment 3

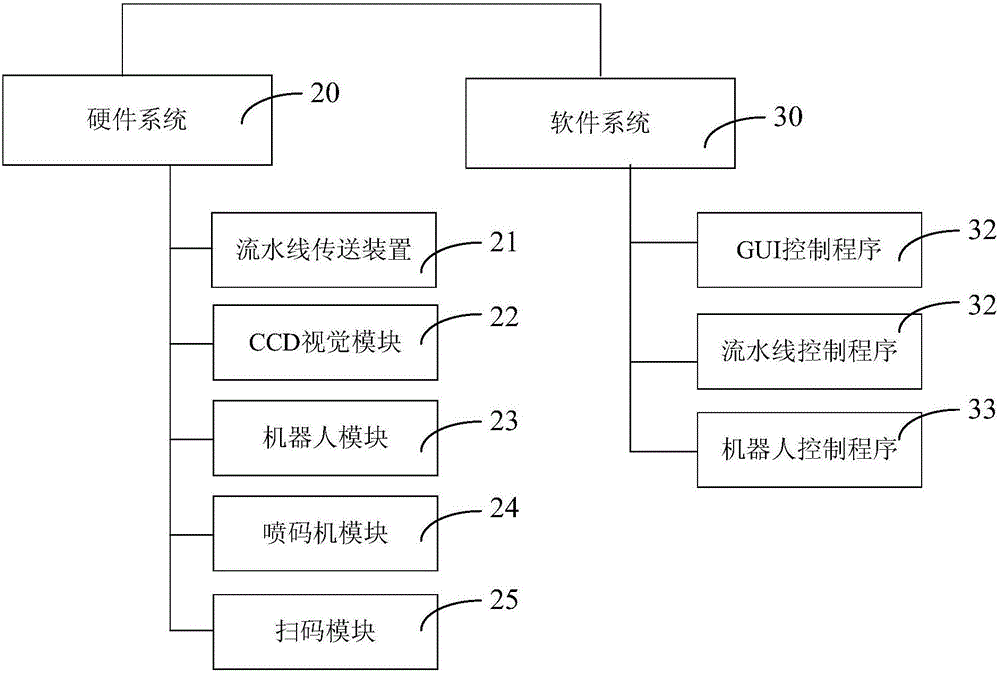

[0064] Such as image 3 As shown, the present embodiment provides a hardware system for realizing the above method and a software system for controlling these hardware systems, wherein the hardware system 20 includes: an assembly line transmission device 21, a CCD vision module 22, a robot module 23, and a coding system Machine module 24 and code scanning module 25, software system 30 includes: GUI control program 31, pipeline control program 32, and robot control program 33, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com