Efficient energy-saving environment-friendly safe oil-water engine and control method

A high-efficiency energy-saving, engine technology, applied in the direction of engine control, engine components, machines/engines, etc., can solve the problems of no substantial improvement of engine fuel consumption, no substantial improvement of energy saving and environmental protection, etc., to improve the instant vaporization effect , prevent the drop, reduce the effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

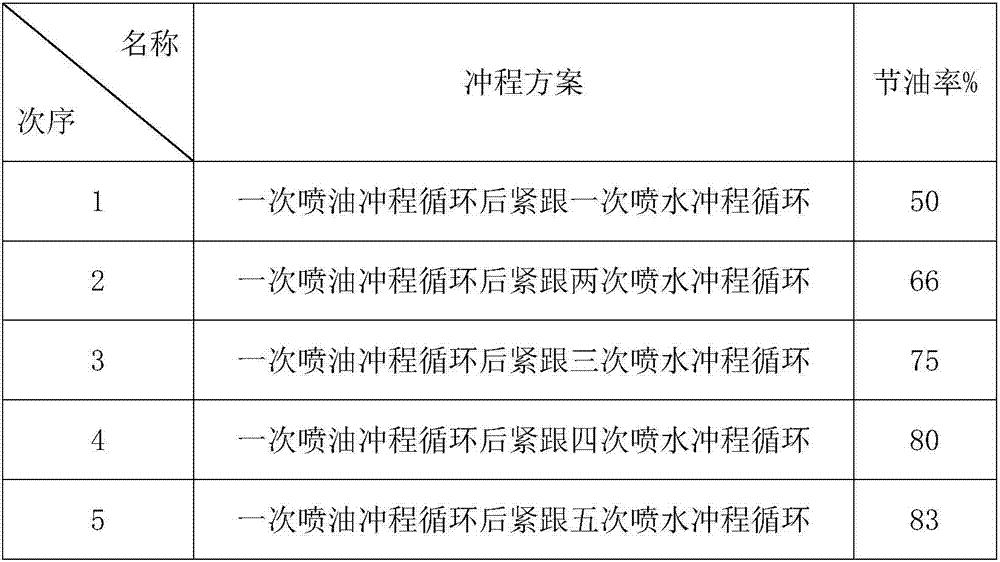

Examples

Embodiment Construction

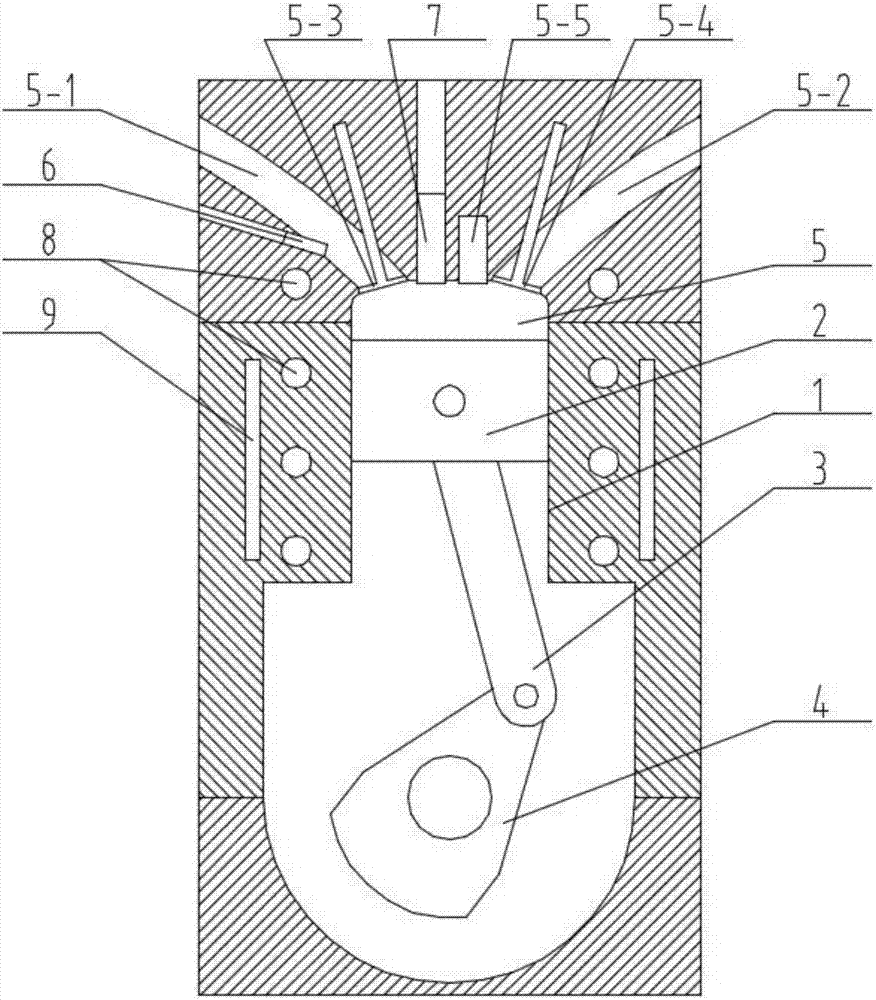

[0034] When the engine is working, due to the friction between the moving parts and the combustion of fuel, a lot of heat is generated. Although there is coolant and air around the cylinder for cooling, a lot of heat is exported, and the lubricating oil can also take away part of the heat, but the engine The parts of the machine still have a very high temperature, and at the same time, due to the different working conditions and structures of each part, the temperature is also different.

[0035] Relevant data reports: When the engine is working, the upper part of the cylinder wall is 120 ℃ ~ 370 ℃, the lower part of the cylinder wall is lower than 150 ℃, the top of the piston is 210 ℃ ~ 425 ℃, the upper part of the piston is 105 ℃ ~ 315 ℃, and the piston skirt is 95 ℃~205℃, the combustion chamber is 2000℃~2500℃.

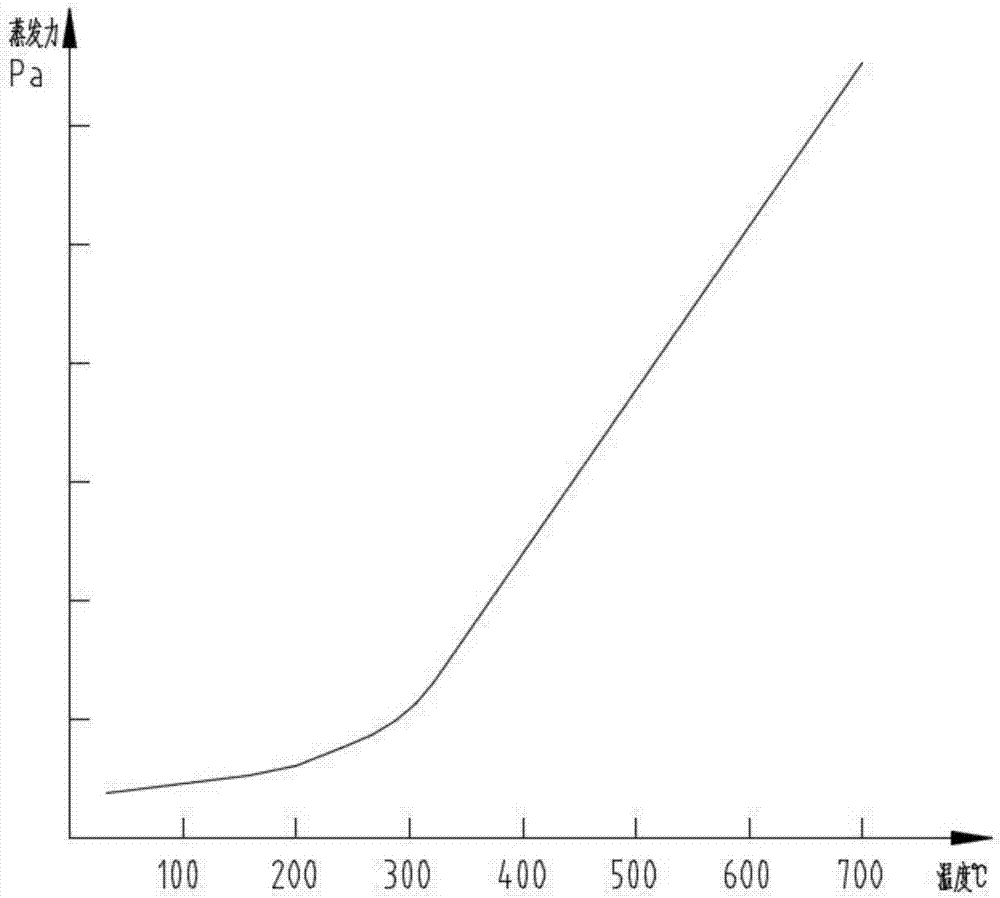

[0036] There are also data reports: when the engine is working, the temperature in the cylinder reaches 300°C to 500°C when the piston compression ends. After gasol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com