Electronic total station apparatus with triaxial compensation function

A total station and functional technology, applied in the field of electronic total station, can solve the problems of difficult adjustment and alignment, complex mechanical structure, low work efficiency, etc. Simple, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

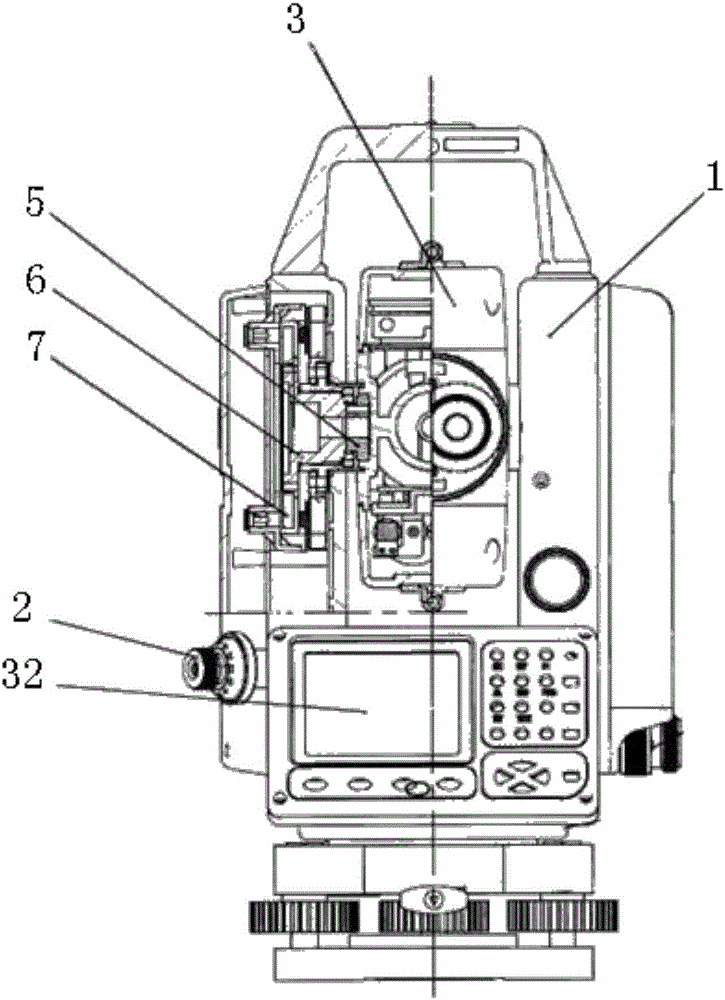

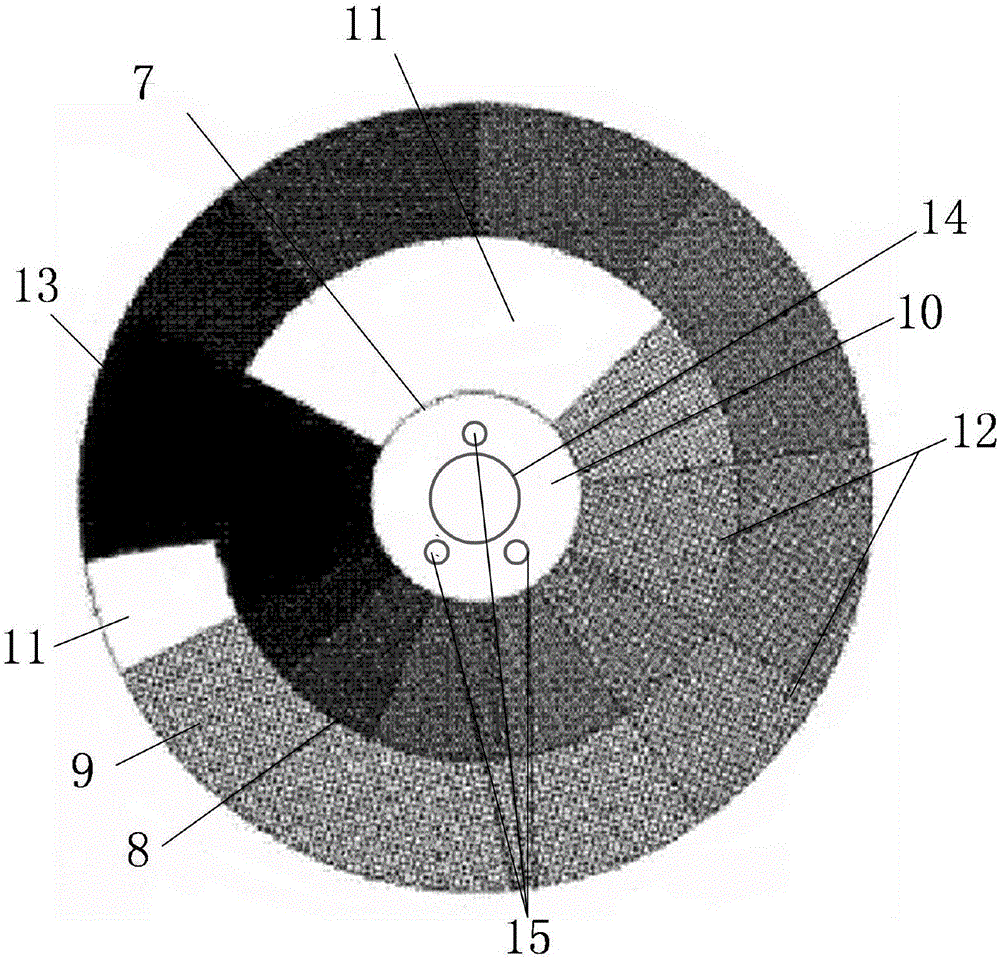

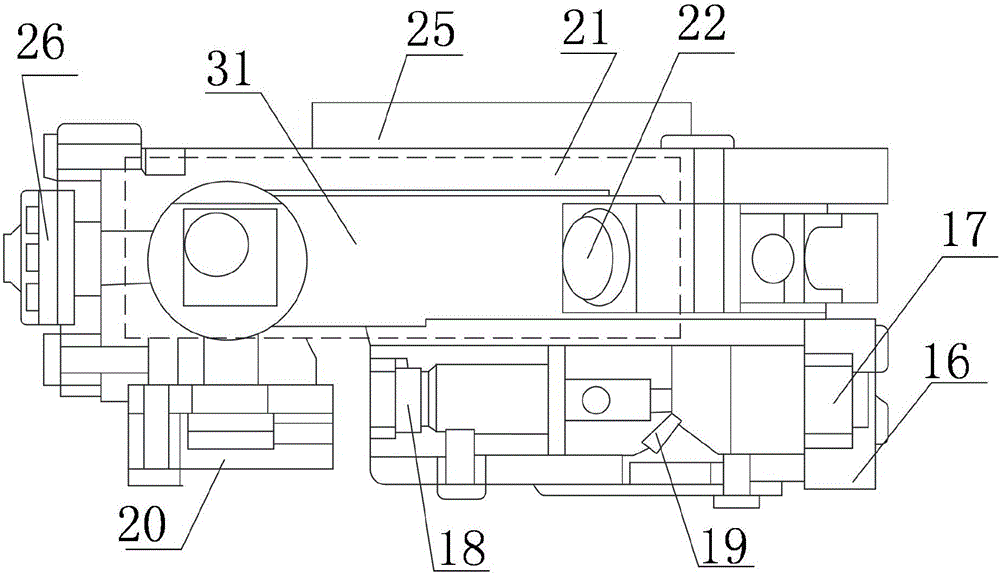

[0031] Such as Figure 1~5 As shown, an electronic total station with three-axis compensation function includes a body 1, a lower laser plummet 2 fixedly arranged on the left side of the body 1, a distance measuring head 3 arranged in the middle of the body 1, and a The body 1 has a light-reducing plate 4 with a position recognition function, and a three-axis compensator arranged inside the body 1; the distance measuring head 3 is connected to the body 1 through a connecting shaft 5 and a horizontal sleeve shaft 6, and the horizontal sleeve A vertical code disc 7 is fixed on the end face of the shaft 6, and a group of photoelectric converters are respectively arranged on both sides of the code disc 7;

[0032] The light-shielding plate 4 is circular, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap