Inclined-type polyhedral-structure thermoelectric arm

A technology of polyhedral structure and thermoelectric arms, which is applied in the field of thermoelectric arms, can solve the problems of poor current uniformity of thermoelectric arms, and achieve the effects of reducing internal resistance, reducing use, and good structural adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The preferred embodiment of the present invention is:

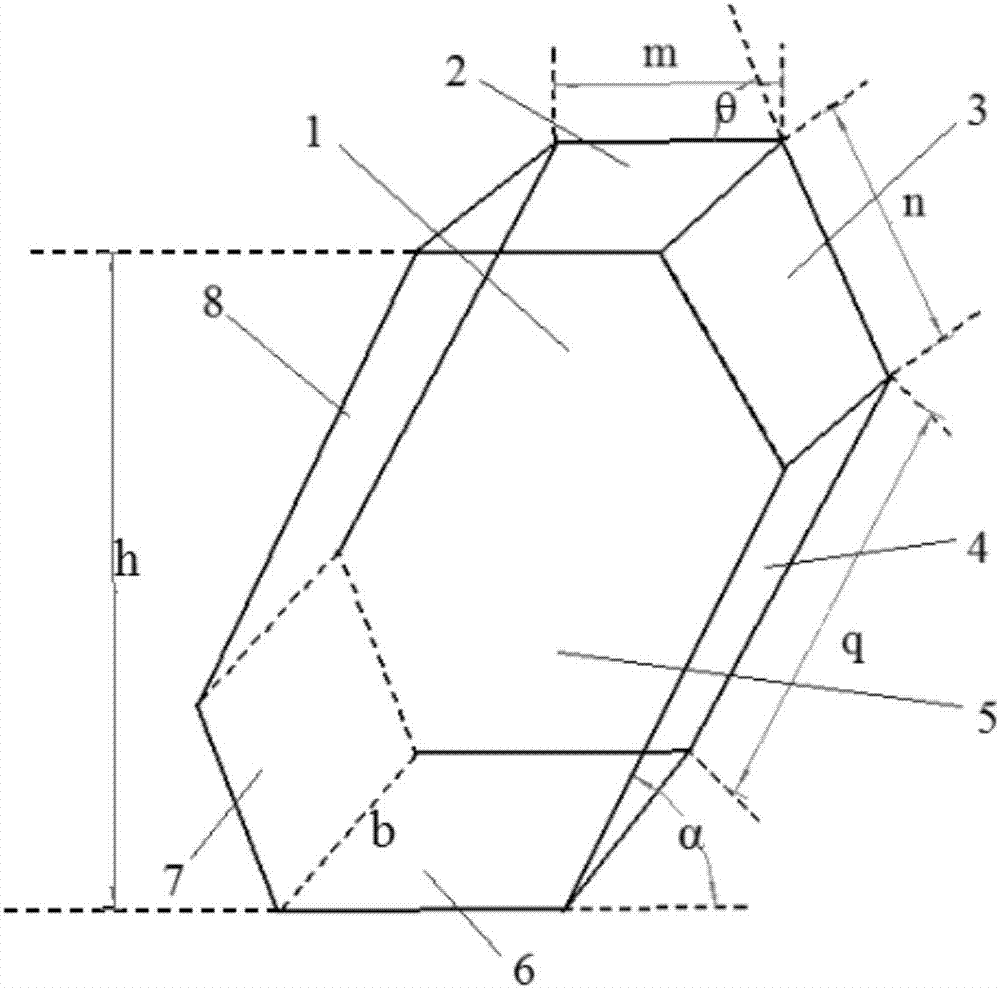

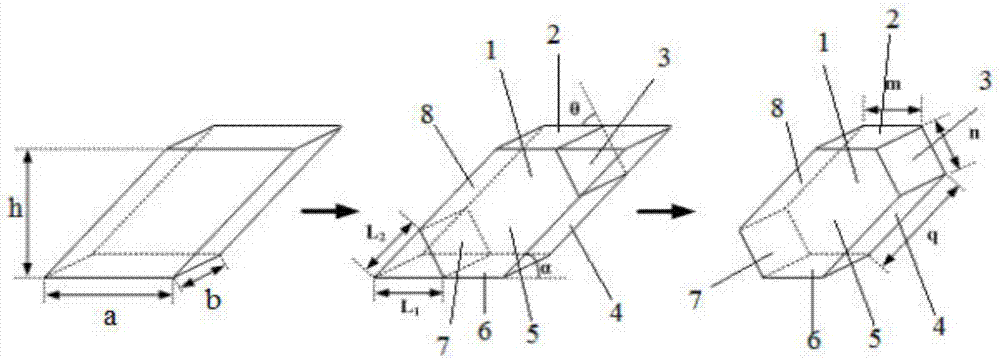

[0027] Such as figure 1 As shown, the three-dimensional structure of the thermoelectric arm of the inclined polyhedron structure is an octahedron structure, and the longitudinal section is a parallelepiped with opposite sides. One 3, cutting surface two 7, bevel one 4 and bevel two 8; described side one 1 and side two 5, bottom surface one 2 and bottom surface two 6, cutting surface one 3 and cutting surface two 7, bevel one 4 and bevel two 8 are parallel and equal in pairs; the side length m of the side and the bottom surface of the octahedron is 5mm, the side length n of the side face of the octahedron and the cutting surface is 3.83mm, and the side length of the octahedron and the inclined plane The common side length q is 9.14mm; the common side length b of the bottom surface of the octahedron and the cutting surface is 10mm, the height h of the octahedron is 10mm, and the inclination angle α of the octahedron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com