Nonvolatile memory based on metal organic perovskite materials and preparation method

A perovskite material and metal organic technology, applied in the field of memory, can solve the problems of difficult regulation, poor mechanical properties, small switching, etc., and achieve the effect of large switching ratio and high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

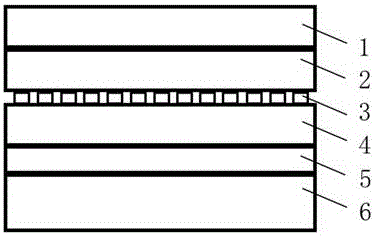

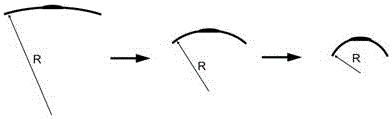

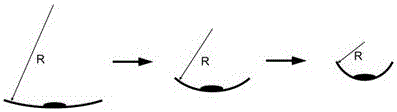

[0055] Mix methyl halide amine with 0.4 mmol lead halide in a molar ratio of 1.0 and dissolve it in 10 mL of dimethylformamide, stir and react for 12 hours to obtain CH 3 NH 3 wxya 3 solution; a 100 nm thick aluminum electrode is used on the PET plastic substrate to form a metal film bottom electrode through a mask in the form of thermal evaporation, and polymethyl methacrylate is spin-coated on the metal film bottom electrode to form the first polymer layer, followed by annealing at 100°C for 1 h; spin-coat CH on top of the annealed first polymer layer 3 NH 3 wxya 3 solution, forming CH 3 NH 3 wxya 3 layer; in CH 3 NH 3 wxya 3 Spin-coat polymethyl methacrylate on top of the second polymer layer to form a second polymer layer; on the second polymer layer, a 100nm-thick aluminum electrode is thermally evaporated to form a metal thin film top electrode, and finally a CH-based 3 NH 3 wxya 3 flexible non-volatile memory.

Embodiment 2

[0057] Methyl halide amine was mixed with 0.3 mmol lead halide in a molar ratio of 1.1 and dissolved in 12 mL of dimethylformamide, stirred for 10 hours to obtain CH 3 NH 3 wxya 3 solution; adopt 80nm thick copper electrode on the PET plastic substrate to form the bottom electrode of the metal film through the mask plate in the form of thermal evaporation, spin-coat polystyrene on the bottom electrode of the metal film to form the first polymer layer, and then Anneal at 90°C for 2h; spin-coat CH on the annealed first polymer layer 3 NH 3 wxya 3 solution, forming CH 3 NH 3 wxya 3 layer; in CH 3 NH 3 wxya 3 Spin-coat polystyrene on top of the second polymer layer to form a second polymer layer; on the second polymer layer, an 80nm-thick copper electrode is thermally evaporated to form a metal thin film top electrode, and finally a CH-based 3 NH 3 wxya 3 flexible non-volatile memory.

[0058] In summary, the present invention provides a flexible non-volatile memory b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com