Catalyst for acetylene dimerization reaction as well as preparation method and application of catalyst

A kind of technology of acetylene dimerization reaction and catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

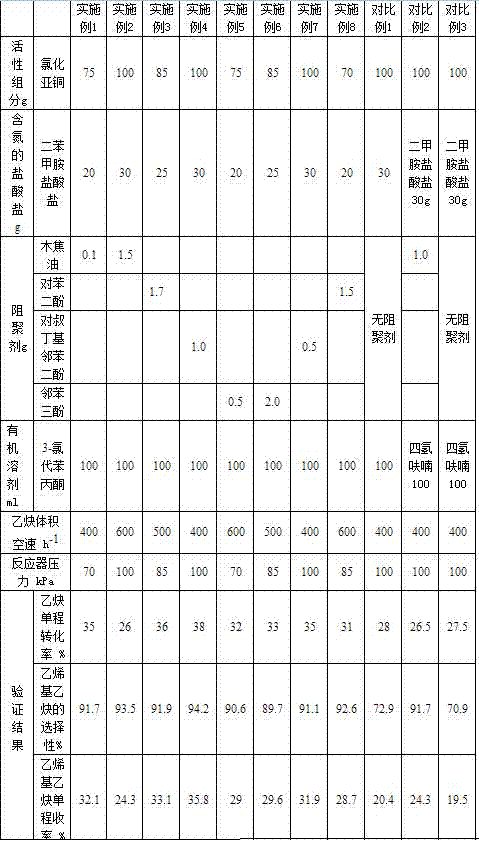

Examples

preparation example Construction

[0022] According to an embodiment of the present invention, in another aspect of the present invention, a preparation method using the aforementioned catalyst for acetylene dimerization reaction is proposed, including the following steps.

[0023] Step 1: In the catalyst configuration device, nitrogen gas is fed, and the organic solvent is added in proportion to the catalyst configuration device at the same time, and nitrogen gas is continuously passed to remove oxygen.

[0024] Step 2: According to the mass content ratio of each component of the catalyst, the nitrogen-containing hydrochloride and the polymerization inhibitor are sequentially dissolved in the organic solvent that removes oxygen, and the stirring is continued until they are all dissolved to obtain a mixed solution .

[0025] Step 3: According to the mass content ratio of each component of the catalyst, the cuprous chloride is dissolved in the mixed solution, and the mixed solution is stirred at 100-120°C and ma...

Embodiment 1

[0027] Example 1: A catalyst for acetylene dimerization, comprising the following components: active component: nitrogen-containing hydrochloride: polymerization inhibitor: organic solvent in a ratio of 75g: 20g: 0.1g : 100ml, wherein, the active component is cuprous chloride; the nitrogen-containing hydrochloride is benzhydrylamine hydrochloride; the polymerization inhibitor is wood tar, hydroquinone, p-tert-butyl o- Hydroquinone or pyrogallol; the organic solvent is 3-chloropropiophenone.

[0028] A preparation method utilizing the aforementioned catalyst for acetylene dimerization, comprising the following steps:

[0029] Step 1: In the catalyst dispensing device, feed nitrogen, press and release the pressure 3 to 5 times to drive away the oxygen, place the weighed 100ml 3-chloropropiophenone solution in the catalyst dispensing device, and continuously blow in nitrogen .

[0030] Step 2: Weigh 20 g of benzhydrylamine hydrochloride and 0.1 g of wood tar and place them in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com