MEMS sensor wafer and splitting method of MEMS sensor wafer

A sensor and sensor unit technology, applied in the field of MEMS sensors, can solve the problems of easy damage of silicon film, increase of silicon film breakage rate, reduction of wafer output rate of silicon gauge pressure sensor, etc., so as to improve dicing efficiency, The effect of reducing dust and improving wafer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

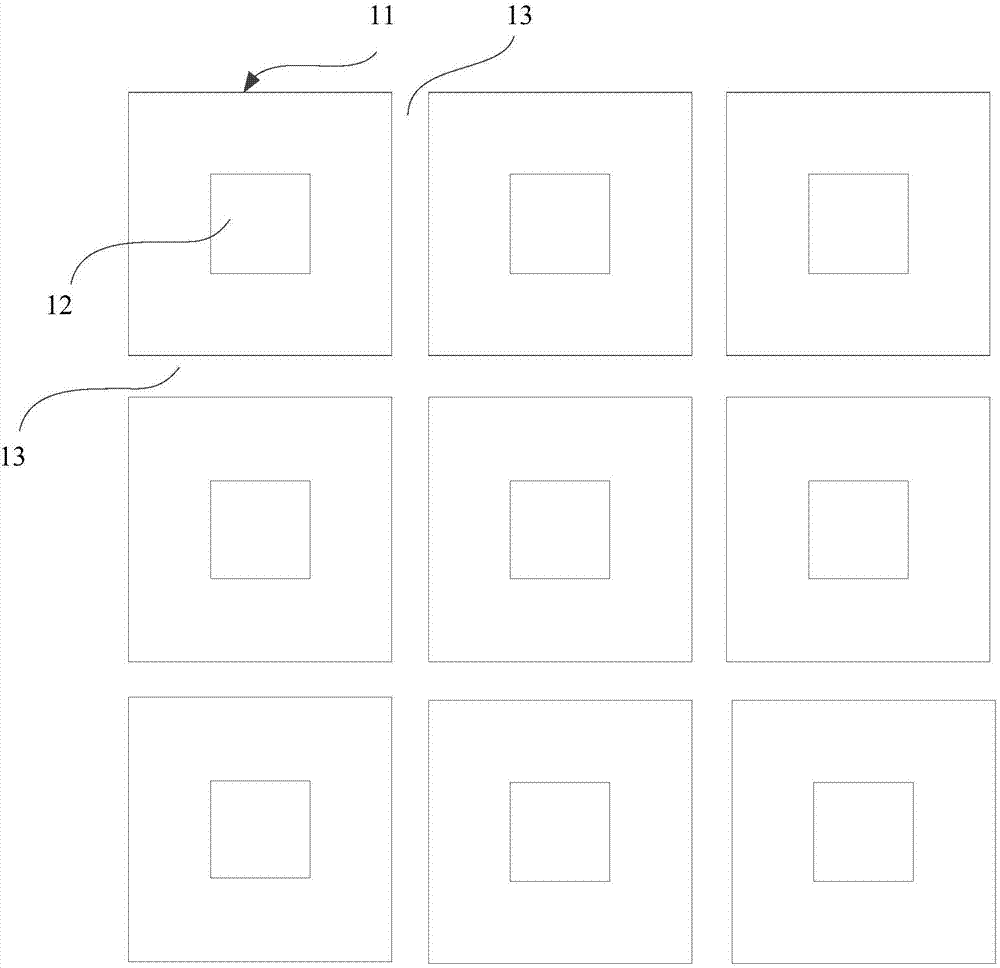

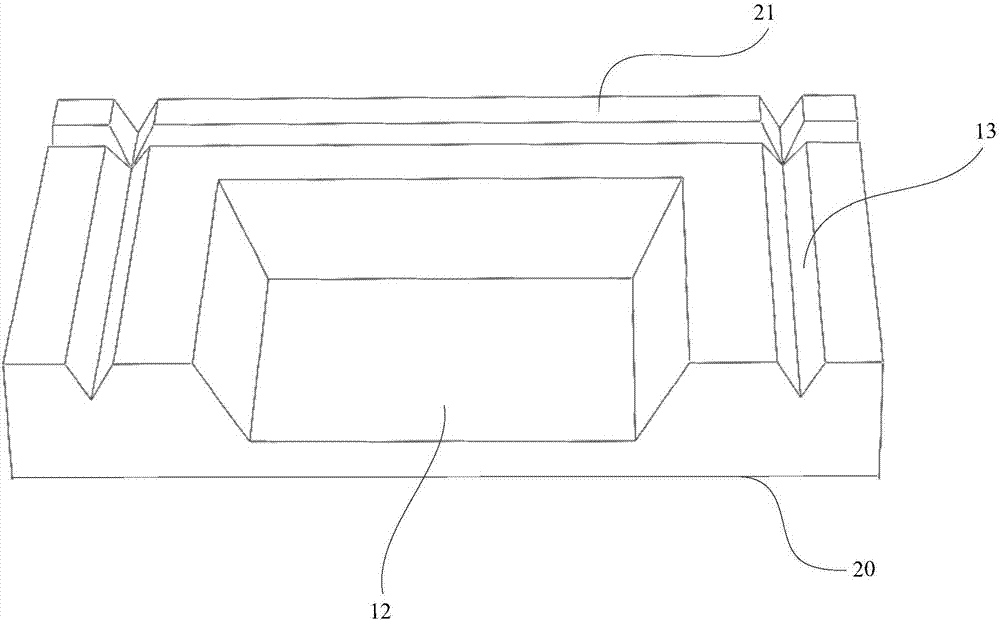

[0031] Please refer to figure 1 , which shows a schematic diagram of a partial structure of a MEMS sensor wafer provided by an exemplary embodiment of the present invention.

[0032] Such as figure 1 As shown, the MEMS (Microelectro Mechanical Systems, Micro Electro Mechanical Systems) sensor wafer includes several MEMS sensor units 11 arranged vertically and horizontally.

[0033] A silicon cup 12 is arranged on the back of each MEMS sensor unit 11, and the location of each silicon cup corresponds to a MEMS sensor structure.

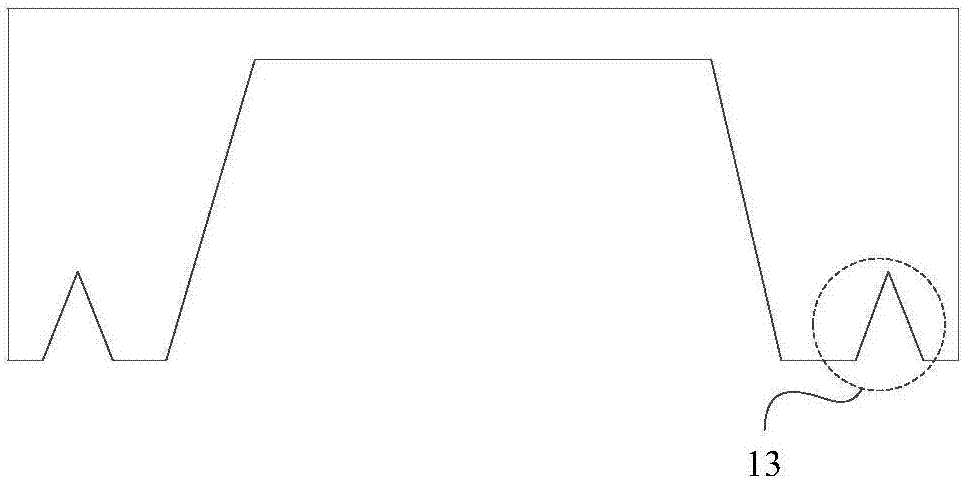

[0034] On the back side of the MEMS sensor wafer, there is a split channel 13 between any two adjacent rows of MEMS sensor units 11 , and there is a split channel 13 between any adjacent two rows of MEMS senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com