Gradient and porous magnesium alloy material used for bone defect repair

A gradient porous, magnesium alloy technology, used in the field of medical devices, can solve problems such as denaturation, easy formation of oxides or inclusions, and easy corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

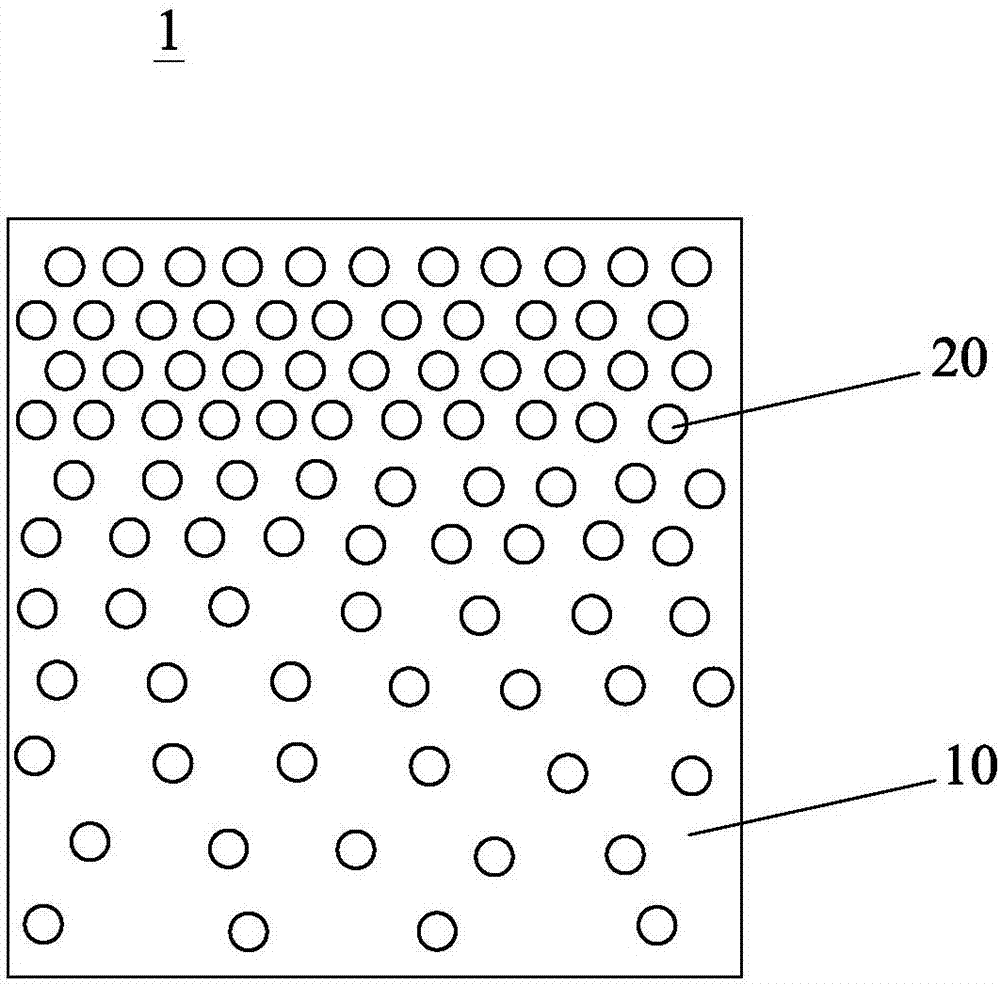

[0021] The present invention aims to provide a gradient porous magnesium alloy material 1 for repairing bone defects, whose degradation speed and mechanical properties can match the bone tissue of the implanted site.

[0022] Such as figure 1 As shown, the gradient porous magnesium alloy material 1 of the present invention is used for bone defect repair, and the gradient porous magnesium alloy material 1 is composed of two kinds of magnesium alloy powder and NaHCO 3 It is prepared by vacuum sintering after powder mixing, including a material body 10 and a number of connected pores 20 distributed inside it, which are distributed in a gradient. The pores include main pores and micropores. The diameter of the main pores is 150-1000 microns The diameter of the pores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com