A multi-stage screening fiber beater

A beater and fiber technology, which is applied to fiber raw materials, fiber raw material processing, textiles and papermaking, etc., can solve the problems of single type of pulp production and low production efficiency, and achieve a wide range of applications, simple structure, and improved output efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

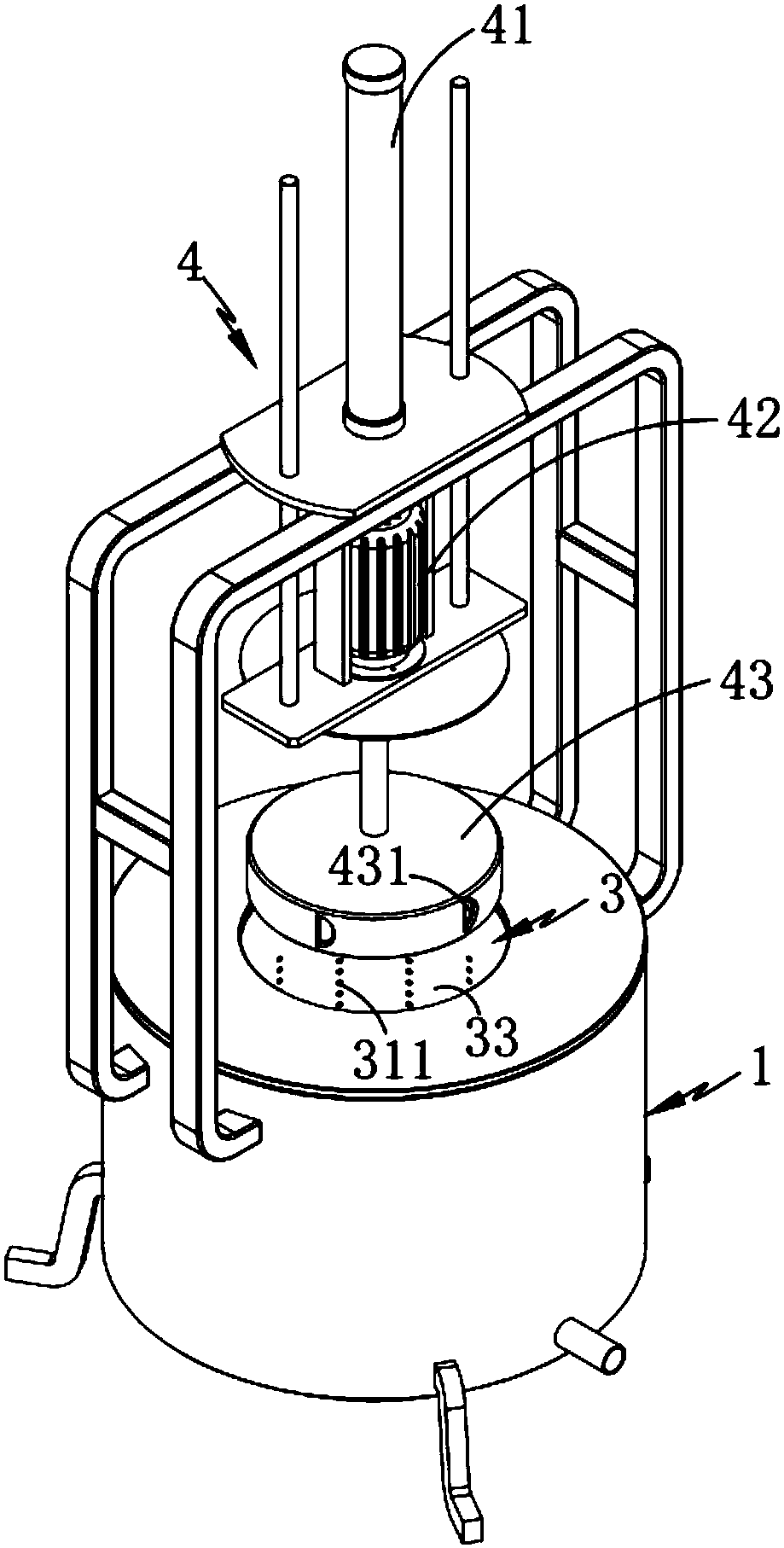

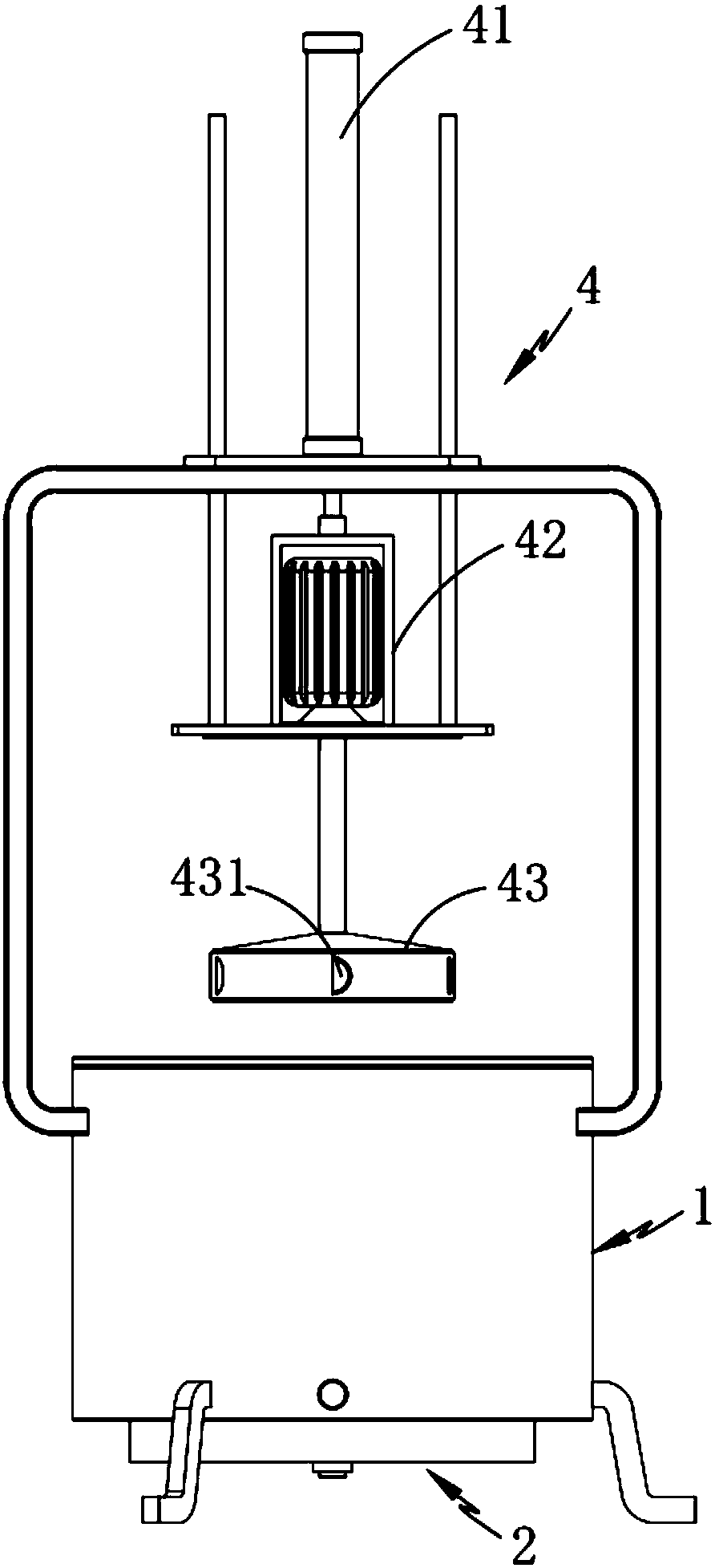

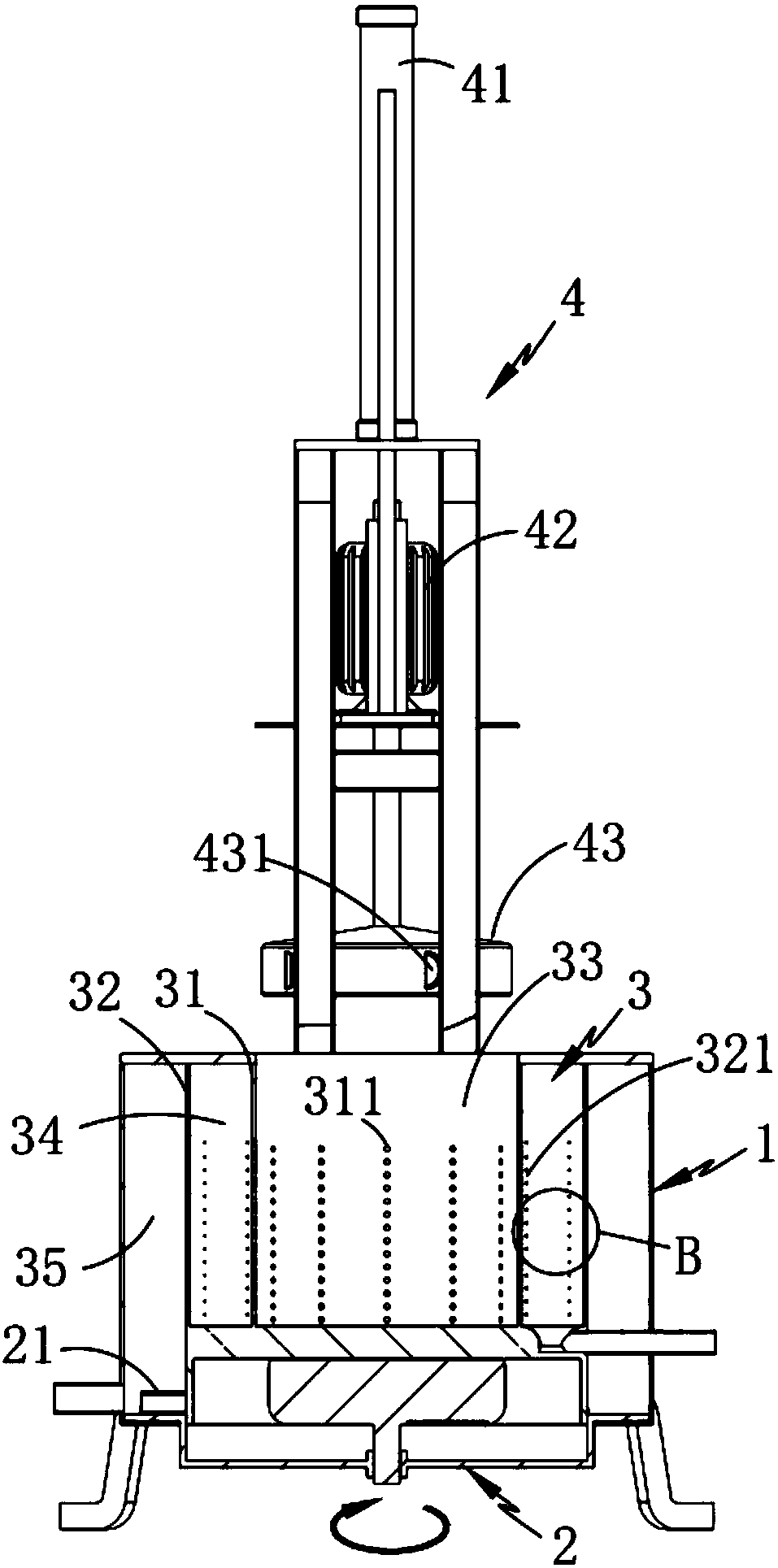

[0037] like figure 1 , 2 , 3, 4 and 5, a multi-stage screening fiber beater includes a beating chamber 1, an output assembly 2, a screening assembly 3 and a grinding assembly 4, the output assembly 2 is circularly arranged, and its rotation is installed on At the bottom of the beating chamber 1, the screening assembly 3 is arranged in an annular shape and is fixedly arranged inside the beating chamber 1. The screening assembly 3 includes a set of The second sieve plate 32 and the first sieve plate 31, the inside of the first sieve plate 31 forms a material addition zone 33, forms a coarse pulp zone 34 between the first sieve plate 31 and the second sieve plate 32, and the second sieve plate 32 A fine pulp area 35 is formed between the outer wall of the beating chamber 1, the material addition area 33 communicates with the coarse pulp area 34 through a number of coarse selection holes 311 provided on the first sieve plate 31, and the coarse pulp area 34 communicates with the f...

Embodiment 2

[0039] The inventor believes that in order to better implement the technical solution, further specific implementation methods are necessary, so the inventor describes the second embodiment on the basis of the first embodiment.

[0040] like figure 1 , 2 , 3 and 4, a multi-stage screening fiber beater, including a cylindrical beating chamber 1, also includes:

[0041] An output assembly 2, the output assembly 2 is arranged in a circular shape, which is rotatably installed on the bottom of the beating chamber 1;

[0042] A screening assembly 3, the screening assembly 3 is ring-shaped and fixedly arranged inside the beating chamber 1, the screening assembly 3 includes second sieve plates located in the beating chamber 1 and arranged at intervals from outside to inside 32 and the first sieve plate 31, the material addition area 33 is formed inside the first sieve plate 31, the coarse pulp area 34 is formed between the first sieve plate 31 and the second sieve plate 32, the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com