Composite waterproof material and waterproof system with composite waterproof material applied

A technology of waterproof material and waterproof film layer, which is applied in the field of composite waterproof materials and waterproof systems, which can solve the problems of short service life, aging and damage of waterproof materials, and achieve convenient construction, prevent damage and aging, and avoid construction damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

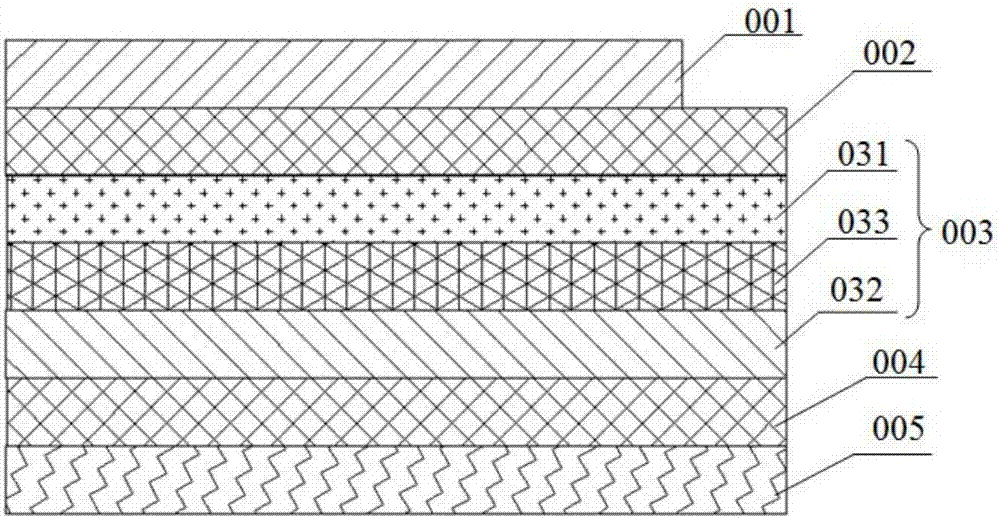

[0061] Embodiment one: a kind of composite waterproof material, such as Figure 4 As shown, it includes non-woven fabric layer 001, first modified asphalt layer 002, grid cloth layer 033, PET non-woven fabric layer 032, second modified asphalt layer 004 and tearable film layer 005 from top to bottom. Wherein, the width of the non-woven fabric layer 001 is 3cm shorter than the width of the first modified asphalt layer 002; by weight percentage, the raw material components of the first modified asphalt layer 002 and the second modified asphalt layer 004 include No. 90 asphalt 50%, SIS thermoplastic rubber 15%, talcum powder 35%, the tearable film layer 005 is PE film, and the thickness of the composite waterproof material is 1.0mm.

Embodiment 2

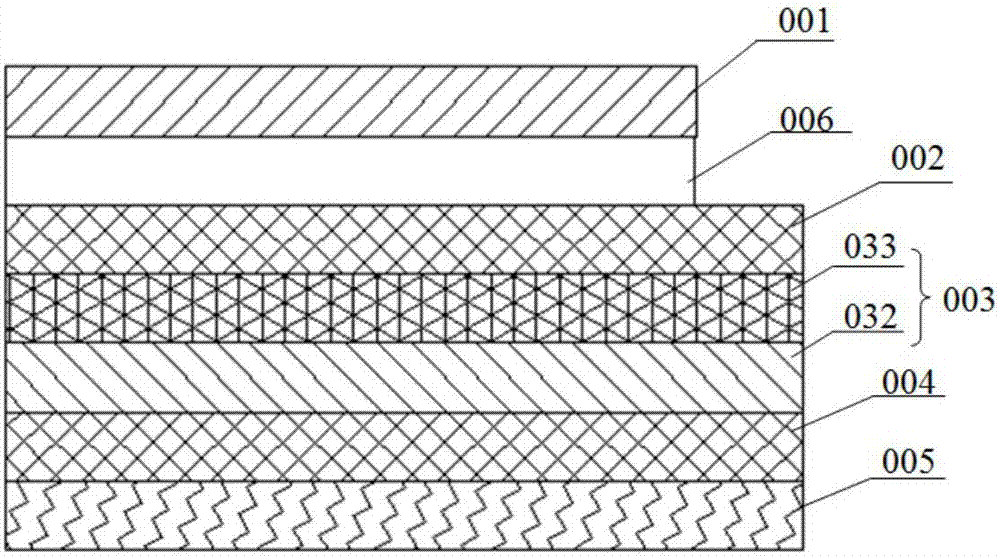

[0062] Embodiment two: a kind of composite waterproof material, such as figure 2 As shown, from top to bottom, it includes non-woven fabric layer 001, waterproof membrane layer 006, first modified asphalt layer 002, grid cloth layer 033, PET non-woven fabric layer 032, second modified asphalt layer 004 and can be Tear film layer 005. Wherein, the width of the non-woven fabric layer 001 and the width of the waterproof film layer 006 are 5cm shorter than the width of the first modified bitumen layer 002; the waterproof film layer 006 is a PET film; in terms of weight percentage, the first modified bitumen layer 002 And the raw material components of the second modified asphalt layer 004 include 55% of No. 80 asphalt, 18% of SBR thermoplastic styrene-butadiene rubber, 27% of talcum powder, and the tearable film layer 005 is PE film, and the thickness of the composite waterproof material is 1.2mm .

Embodiment 3

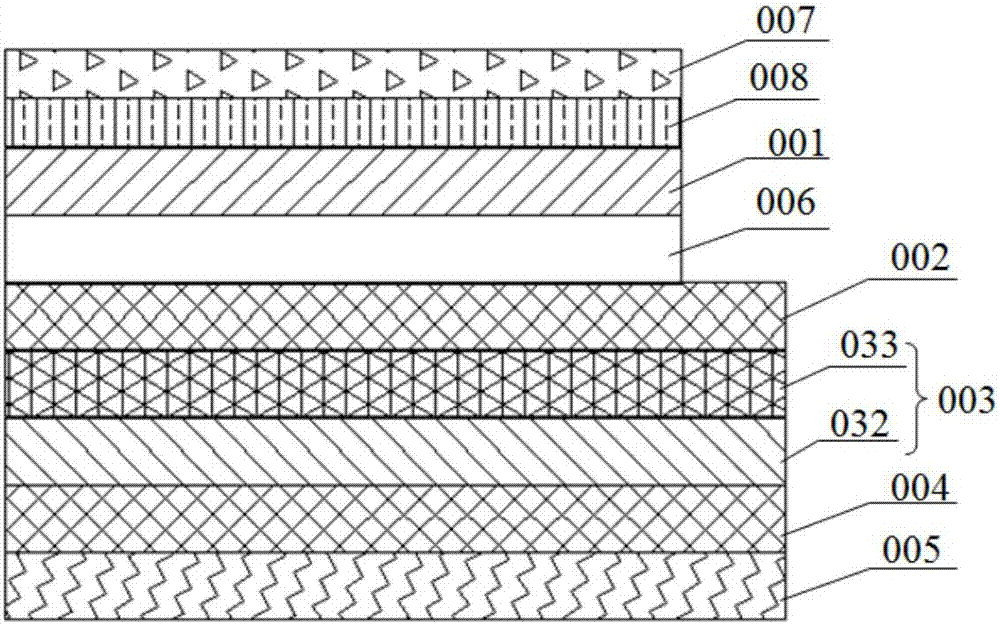

[0063] Embodiment three: a kind of composite waterproof material, such as Figure 5 As shown, it includes a non-woven fabric layer 001, a first modified asphalt layer 002, a PET film layer 031, a second modified asphalt layer 004, and a tearable film layer 005 from top to bottom. Wherein, the width of the non-woven fabric layer 001 is 7 cm shorter than the width of the first modified asphalt layer 002; in terms of weight percentage, the raw material components of the first modified asphalt layer 002 and the second modified asphalt layer 004 include No. 90 asphalt 40%, APP thermoplastic rubber 18%, talcum powder 42%, tearable film layer 005 is PE film, and the thickness of the composite waterproof material is 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com