Steel bar planting construction method applied to inorganic anchoring material

A technology of anchoring materials and construction methods, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems affecting the construction quality and service performance, and the water absorption of anchor glue in paper bags is not easy to control, so as to avoid inconvenience and Effects of uncertainty, stable anchoring performance, and wide range of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

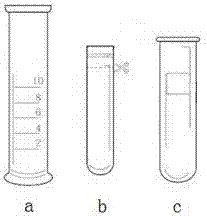

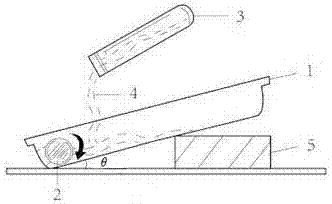

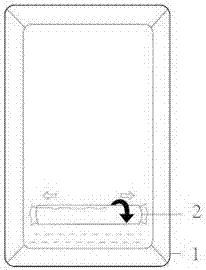

Embodiment 1

[0027] Choose an anchor bag containing about 40g of magnesium phosphate cement-based anchoring material, fill the tube with a quantitative plastic hose with a full volume of 5.2mL (add water according to its optimal water-to-powder ratio of 0.13), and pour it into a square plate with rounded corners , And put a cushion block on the bottom of the square plate so that the bottom surface is at an inclination angle of 10°~30° with the horizontal; put the anchor bag parallel to the top of the position of the water in the square plate, let it stick to the bottom surface of the square plate, along The bottom surface of the square plate slowly rolls down into the water, and rolls in place and on the left and right sides, so that the anchor pack can evenly absorb the water; then the anchor pack with quantitative water absorption is stuffed into a concrete hole with a diameter of 20mm and a depth of 100mm. Ribbed steel bars with a diameter of 16mm are slowly inserted in the same direction...

Embodiment 2

[0030] Choose an anchor bag containing about 140g of magnesium phosphate cement-based anchoring material, fill the tube with a quantitative plastic hose with a full volume of 18.2mL (add water according to its optimal water-to-powder ratio of 0.13), and pour it into a square plate with rounded corners Place a cushion block on the bottom of the square plate so that the bottom surface is at an inclination angle of 10-30° to the horizontal; place the anchor bag parallel to the top of the position of the water in the square plate, and let it stick to the bottom surface of the square plate, along the The bottom surface of the square plate slowly rolls down into the water, and rolls in place and on the left and right sides, so that the anchor pack can evenly absorb the water; then the anchor pack with quantitative water absorption is stuffed into a concrete hole with a diameter of 25mm and a depth of 300mm. The ribbed steel bars with a diameter of 20mm are slowly inserted in the same ...

Embodiment 3

[0033] Choose an anchoring bag containing about 29g of sulphoaluminate cement-based anchoring material, fill the tube with a quantitative plastic hose with a full scale of 8.7mL (add water according to its optimal water-to-powder ratio of 0.30), and pour it into a round chamfer In the square plate, put a cushion block on the bottom of the square plate so that the bottom surface and the horizontal direction are inclined at 10-30°; place the anchor bag parallel to the position of the water in the square plate above the bottom surface of the square plate , Slowly roll down the bottom surface of the square plate to the water surface, and roll in place and on the left and right sides, so that the anchor pack can evenly absorb the water; then the anchor pack with quantitative water absorption is inserted into the concrete hole with a diameter of 20mm and a depth of 100mm , Use a ribbed steel bar with a diameter of 16mm to slowly rotate and insert in the same direction until the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com