Roadway support truss and mounting method thereof

A roadway support and truss technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems that the support performance cannot meet the safety requirements, and achieve the effects of convenient transportation, reduced labor intensity of workers, and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

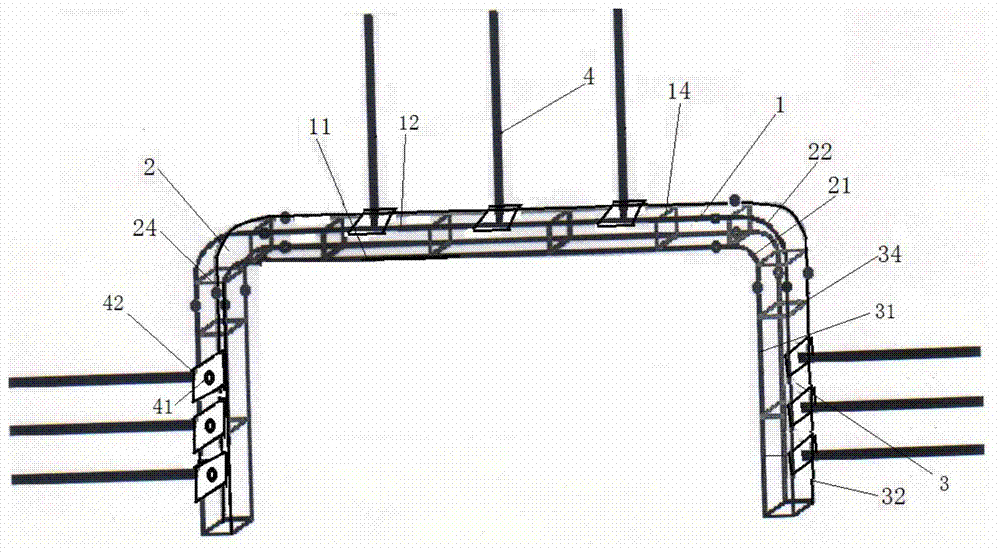

[0016] Such as figure 1 As shown, the present invention includes a top beam frame 1, two shoulder arc frames 2, two column leg frames 3, several anchor rods 4, several pin shafts 5 and concrete cladding layers 6.

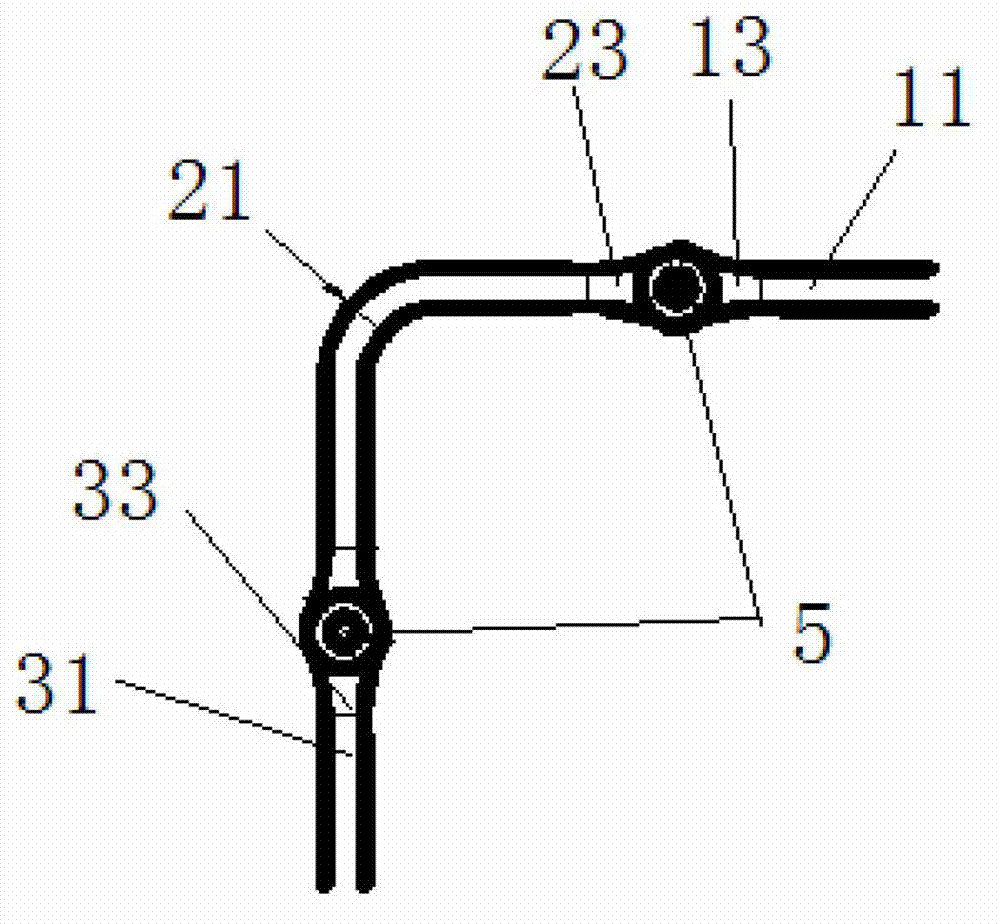

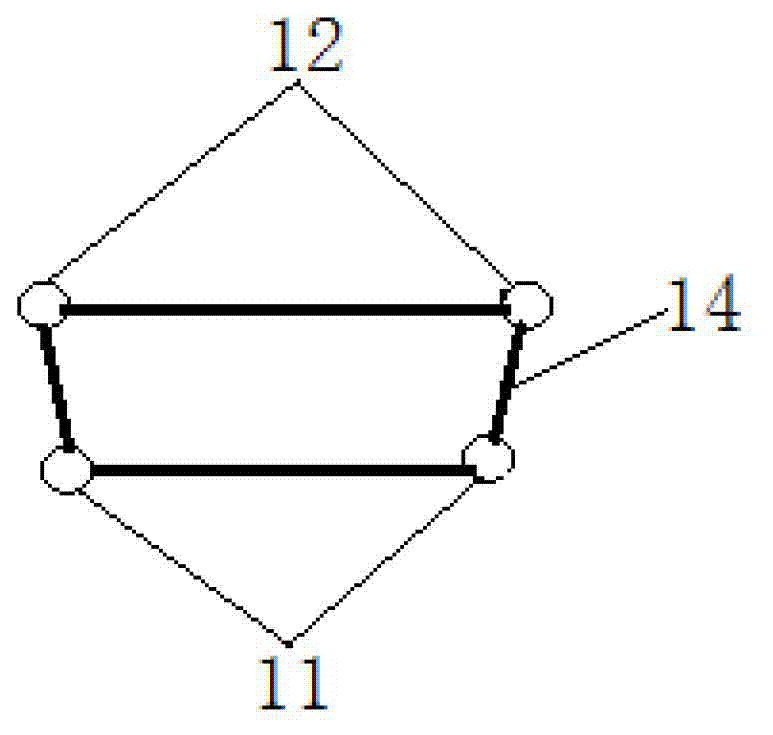

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the roof beam frame 1 of the present invention includes two roof beam main ribs 11 arranged at intervals below and two roof beam auxiliary ribs 12 arranged at intervals above, and each roof beam main rib 11 and two roof beam auxiliary ribs 12 A connecting piece 13 with a hinge hole is welded at each end, and a plurality of reinforcement bars 14 connecting the main rib 11 and the auxiliary rib 12 of the roof beam are arranged at intervals along the length direction of the main rib 11 of the roof beam and the auxiliary rib 12 of the roof beam.

[0018] The shoulder arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com