Method and device for determining setting depth of heat preservation, heat insulation and eccentric wear prevention oil pipe

A technology for thermal insulation and oil pipe grinding, which is applied in drilling equipment and methods, earthwork drilling, measurement, etc., and can solve the problems of increased energy consumption, increased load of pumping units, and poor fluidity of crude oil wells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

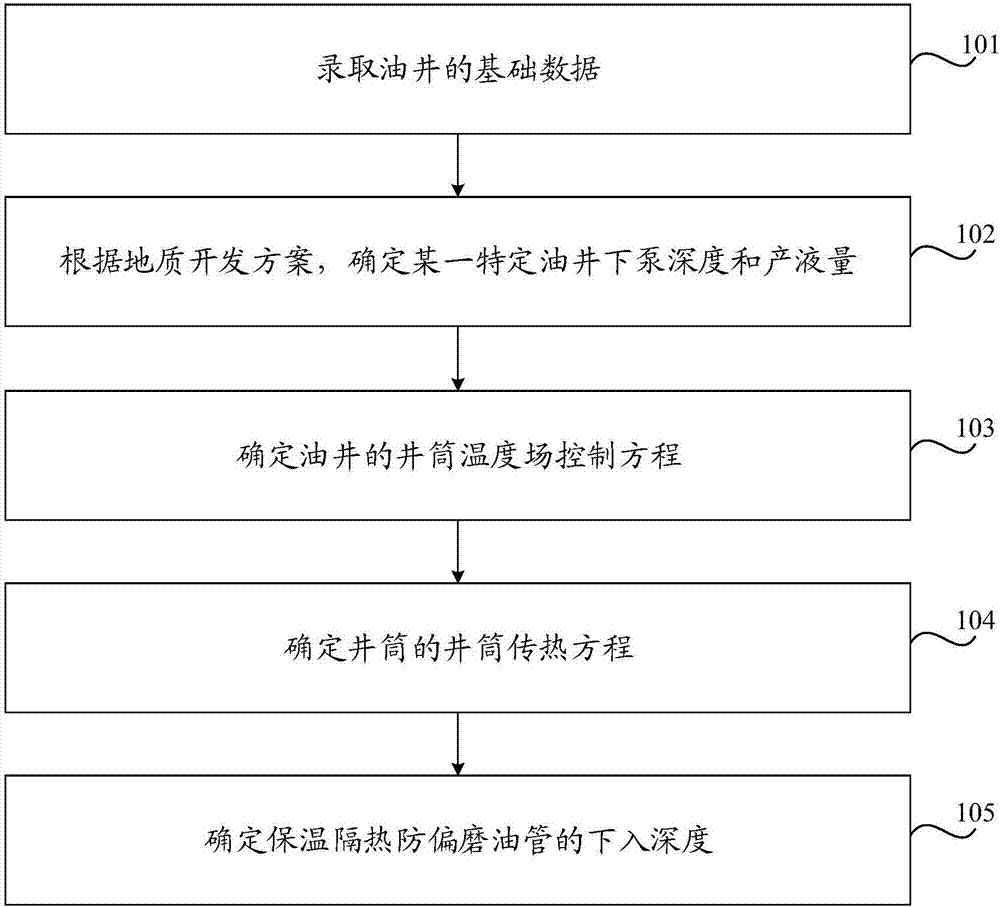

[0070] Embodiment 1: The embodiment of the present invention provides a method for determining the running depth of thermal insulation and anti-eccentric wear tubing. The embodiment of the present invention takes the method applied to Well Jin XXX-12 as an example to describe the method. Such as figure 1 As shown, the method can include:

[0071] Step 101: Enroll basic data of the oil well. The basic data of the admission can include: the depth L of the oil layer of a specific oil well, the geothermal gradient t d , Well deviation angle α, azimuth angle φ.

[0072] Step 102. Determine the downpump depth H and liquid production volume Q of a specific oil well according to the geological development plan 1 .

[0073] Step 103: Determine the wellbore temperature field control equation of the oil well.

[0074] Take the centerline of the wellbore of the oil well as the X-axis, and its positive direction is from the bottom of the well to the wellhead; perpendicular to the centerline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com