Fairing for nonmetal expansion joint expansion gap

An expansion joint, a non-metallic technology, applied in expansion compensation devices for pipelines, heat preservation, pipes/pipe joints/fittings, etc., can solve problems such as distortion, expansion joint skin cracking, sparks, etc., and achieve expansion coefficient Minimize the effect of eliminating deflector deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is further described:

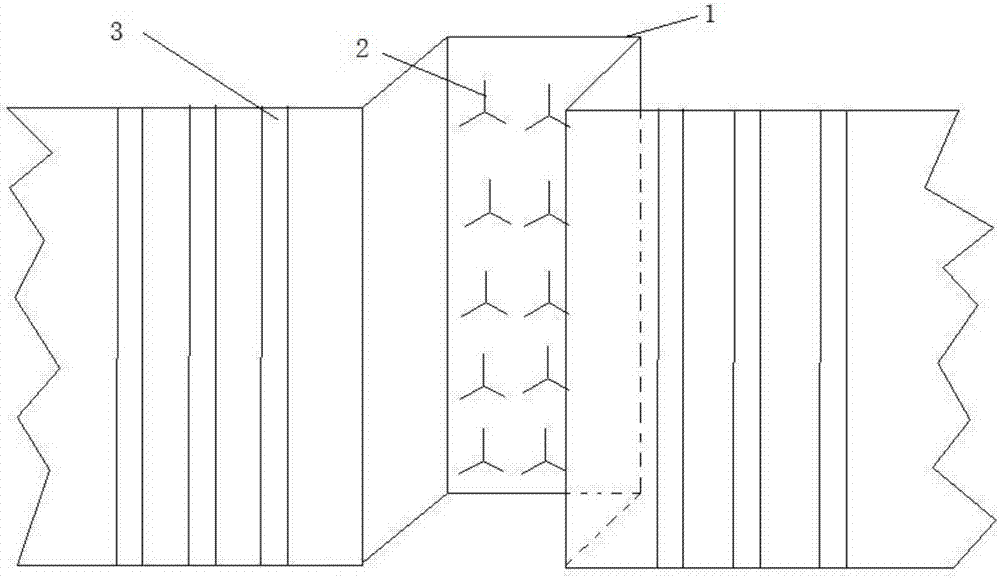

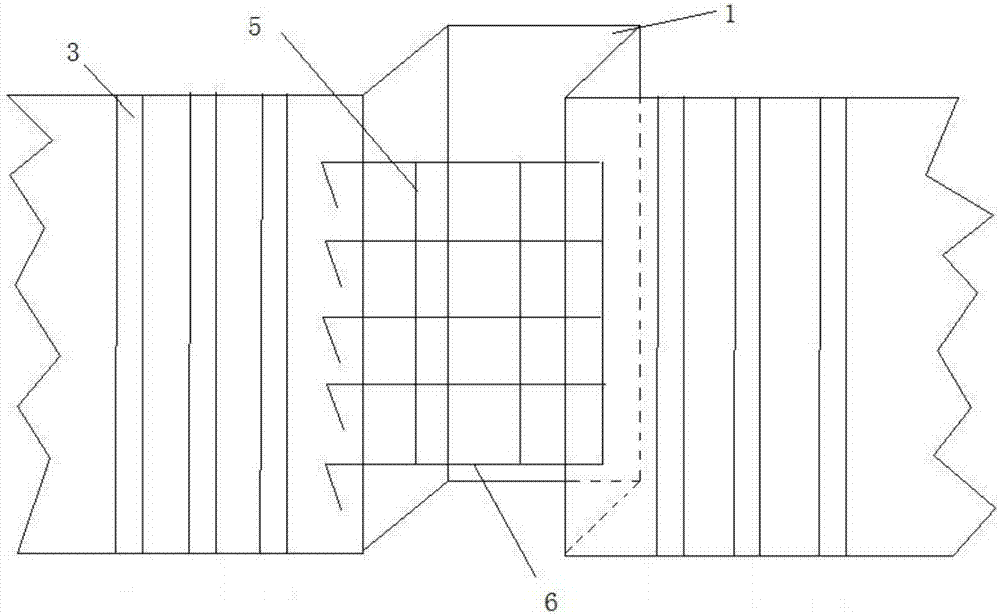

[0019] see figure 1 and figure 2 , a deflector for the expansion gap of a non-metallic expansion joint, including a steel plate 1, L-shaped steel bars 6, tie bars 5 and corundum mullite self-flowing castable; the steel plate 1 is a steel plate with a groove, and the bottom of the groove is poured There are corundum mullite self-flowing castables; several L-shaped steel bars 6 are welded across and arranged above the groove, and are parallel to each other; several tie bars 5 are vertically welded on the L-shaped steel bars 6 to form a steel mesh; the steel mesh is poured Corundum mullite self-flowing castable, an expansion gap is formed between the steel mesh and the groove.

[0020] A number of V-shaped nails 2 are welded on the bottom of the groove and the tie bars 5 , the V-shaped nails 2 are evenly arranged, and the corundum mullite self-flowing castable is poured togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com